Filtration Process In Gold Processing Plants

mineral processing

mineral processing mineral processing Dewatering: Concentrates and tailings produced by the methods outlined above must be dewatered in order to convert the pulps to a transportable state. In addition, the water can be recycled into the existing water circuits of the processing plant, greatly reducing the demand for expensive fresh water. Filtration is the separation of a suspension into a ...

Appliions of filtration in the ...

· Appliions of filtration in the pharmaceutical industry. March 16, 2020. As technology advances, both existing and new methods of filtration can capitalize on better, more efficient filters and methods of employing them within the pharmaceutical industry. Mark Ligon. Load More Content.

filtration process in gold processing plants

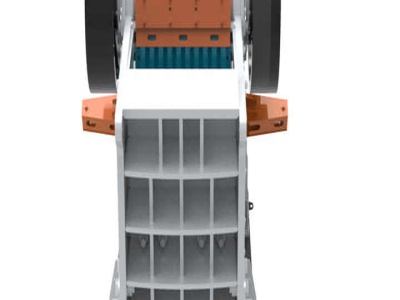

filtration process in gold processing plants ; Latest Projects. K Series Mobile Crushing Plant. K Series Portable Crusher Plant, also known as K Series Portable Crusher, Crawler Mobile Crusher. Crawler Mobile Crusher is a fully hydraulic tracktype mobile crusher developed and completed in order to satisfy higher user demands. Mobile Vibrating Screen . Mobile Vibrating Screen is equipment ...

Processes

Focussing on the gold industry, Gekko replace highenergy whole ore treatment of gold by carboninleach (CIL) methodologies with beneficial lowenergy process solutions. Harnessing both gravity separation and floatation, as well as dramatically reducing the initial mass to be processed by preconcentration, Gekko flowsheets increase the grade for downstream intensive processing. This ...

What is nanofiltration?

· These processes took the separation spectrum from the traditional cut point limit of standard filtration of around mm (10 μm) to the very finest distinct solids, a few nanometres in size, and enabled the separation of large molecules from solution. The actual size ranges vary somewhat from source to source, but there is general agreement that microfiltration covers the range 10 μm down ...

Mineral Processing Equipment

For over 45 years, Multotec has focussed on supplying process technology solutions aimed at reducing the operating costs of mineral processing plants.. Driven by a global team of process engineers and metallurgical specialists, Multotec designs, builds, manufactures, installs and maintains equipment throughout the entire value chain of mineral processing plants across all commodity sectors ...

Optimizing juice processing

The most common process in conjunction with apple juice concentration is evaporation. Reverse osmosis can be used here to provide a better total solution. Reverse osmosis is normally capable of removing 50% or more of the water content prior to evaporation, making it possible to significantly reduce overall costs. Concentration levels of up to 20–22 Brix can be achieved. Juice processing ...

Minerals And Mining (Health, Safety and Technical ...

Risk assessment for gold processing plants that use cyanide 221. Training of staff working in gold processing plants that use cyanide 222. First aid in gold processing plants that use cyanide 223. Personal protective equipment 224. Technical support to be supplied by manufacturers, suppliers and distributors of cyanide 225. Procurement of cyanide 226. Transportation of cyanide 227. Warehousing ...

Membrane Filtration Plants

SiccaDania Filtration customised standard solutions approach allows for a unique, yet standardised design. All filtration plants are "Plug Produce", easy to maintain, operate and adapt to future requirements. The membrane filtration plants are all designed to .

Nano filtration and Reverse Osmosis

Nano filtration and Reverse Osmosis are both techniques to bring into action univalent and bivalent ions. Nano filtration. Nano filtration is a technique that has prospered over the past few years. Today, nano filtration is mainly applied in drinking water purifiion process steps, such as water softening, decolouring and micro pollutant removal. During industrial processes nano filtration ...

Wastewater Treatment and Management

Sedimentation must precede all biological filtration operations. The organic matter remaining after primary treatment is extracted by biological secondary treatment processes to meet effluent standards. Secondary treatment commonly is carried out using activatedsludge processes, trickling filters, or rotating biological contactors. In the activatedsludge method, wastewater is fed ...

Lihir Facts

Lihir processing plant is designed to process Mtpa of ore containing % sulphide sulphur at a gold grade of up to 13 g/t and a plant availability of 86%. The instantaneous design feed rate is 375 t/h of ore containing 27 t of sulphide sulphur. There is a legal obligation under the mining permit to examine the potential for a production expansion. A simplified ...

MECHANICAL DEWATERING USING FILTER PRESSES TECHNOLOGY

Thanks to its plant of 8000 and a very complete manufacturing equipment, FAURE EQUIPEMENTS works in accordance with the specific standards in force and its own quality procedures. Communiion and computing are widely developed. FAURE EQUIPEMENTS Filter presses Page 3 MECHANICAL DEWATERING USING FILTER PRESSES TECHNOLOGY Introduction I ) Conventional filter .

Membrane filtration solutions | Tetra Pak

Membrane filtration is the natural way to optimize the value of dairy and plant based products and to reuse water. The technology is used for creating fermented products such as skyr and Greek yogurt, whey proteins for infant, sports, and senior nutrition, for concentrating plant based proteins – and for recovering water from milk and fruits to be used in the production process instead of ...

Membrane technology

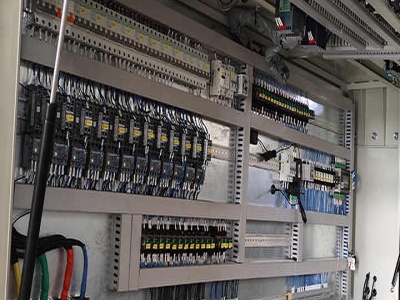

Process management of membrane filtration systems Membrane filtration systems can be managed in either deadend flow or crossflow . The purpose of the optimisation of the membrane techniques is the achievement of the highest possible production for a long period of time, with acceptable pollution levels.

Incineration Processes and Environmental Releases

Other processes for mercury removal are granular activatedcarbon filtration in fixedbed reactors, selenium porousmedia filter, goldamalgamation filter beds, sodium sulfide injection, and wet scrubbing with mercuryreactive solutions. None of those techniques is used commercially in the United States, but fixedbed carbon adsorbers used in Europe often produce mercury and dioxin removal ...

Oil Processing Plant Suppliers | Refinery Plant ...

Mectech is one of the leading Oil Processing Plant Manufacturers Suppliers in India and abroad. We are into manufacturing of customized plant machinery, turnkey projects for Oil Fats Industry. The projects offered by Mectech include, Solvent Extraction Plant, Oil Processing Plant, projects for value addition, Bio Diesel Filters, and Edible Oil Refinery Plant in India and abroad. In its ...

Membranetechnology | Dairy Processing Handbook

All the above techniques feature pressure driven membrane filtration processes in which the feed solution is forced through the membrane under pressure. The membranes are egorized by their salt retention (RO and NF) molecular weight cutoff (NF and UF) or nominal pore size (MF). The cutoff is supposedly the molecular weight of the molecule that has a 90 % rejection by the membrane. .

9 Step Process for Discovering, Mining Refining Gold

· It seems that many have thought on the "gold" mentioned in the Bible and having done so, think further about the processing of it spiritually in one's own life. The temple was covered in gold. We go through processes in our lives too so that God can clothe us in His righteousness – not our own, and it is a costly process and timeconsuming but the value of it will one day be revealed ...

Latest Posts

- تهتز الشاشة spesifikasi

- الطمي مصنع معالجة الذهب

- 200 الهيدروكربونات النفطية المنتجة كسارة الفحم المحمول في مصر

- معالجة خام الحديد بمطحنة الكرة

- بيع كسارة الحجر renta

- مصنع الصين في العلامة التجارية المعدات الزراعية

- برنامج التدرج الكلي للخرسانة

- مصغرة كسارة الحجر المستعملة السعر

- كسارة الفك الصناعية 36x20 الأعمال

- معلومات خط تكسير الجرانيت

- معالجة المعادن من الحجر الجيري

- تعدين الذهب كوم الصين

- مخطط تخطيط محجر الجرانيت

- شاشة تهتز دوارة من الفولاذ المقاوم للصدأ للمغناطيسي

- العالم أفضل الصانع صخرة محطم

- Jaw Crusher Bearings Manufacturers

- Proses Corex Smelting Reduction

- Coal Crusher Plates

- Crusher Grinder X From Termokimik

- Design Of Coal Fired Power Plant Mini 50 Mw Power Plant

- Stone Counterattack Broken Grinder

- Gold Trommel Wash Plant For Sale

- Gold And Dimond Mining In South Amerca In Century

- A R Gutierrez Feed Mill Plant Batal Santiago City Isabela Map

- Cement Grinding Aid Propycol

- Silica Quartz Environmental Impact Study Mine

- Mets Vsi Crusher Spares Part List

- Ltd Kunshan Branch Fine Grinder

- Mount Kalayo Iron Ore Mining

- Used Lagler For Sale