Rate Of Ton Coal Crusher Plant

Jaw Crushers | McLanahan

Tons per hour rate needing to be crushed; Desired size of discharge material needed; Operating hours per day. F100 is the maximum gape opening on a Jaw Crusher. F80 is the feed size to the Jaw Crusher, calculated by taking 80 times the gape opening divided by 100. P80 is the percent passing the closed side setting in tph.

Coal preparation plant process and equipment for coal ...

Taking a coal washing plant in Indonesia as an example, the coking coal preparation plant with an annual processing capacity of 4 million tons can increase the processing capacity per hour to more than 700 tons, and the power consumption, media consumption, fuel consumption, and water consumption are all reduced. At present, the whole plant consumes kg. / ton, flotation fuel consumption 0 ...

rate of 60 ton coal crusher plant

A Readings of Coal Handling Plant Item description Readings Input Size of coal in crusher 250 mm Output size of coal in crusher 20mm cleared in less time to avoid demerge cost given to Belt Loading Factor 60 ton Amount of Coal in wagon 70 ton Coal stuck in clamps of tippler 10 kg Total CHP motor consumption 1500 kW...

Rate Of Ton Coal Crusher Plant

Rate Of Ton Coal Crusher Plant. Mar 27 2019nbsp018332At present the whole plant consumes 142 kg ton flotation fuel consumption 067 kg ton dry slime water consumption 009 cubic meters ton electricity consumption 932 degrees ton In 2017 it imported 1682 million tons of raw coal produced 977000 tons of clean coal products recovered 5935 of clean coal and created a profit of . Send Email: [email ...

Boundary Dam 3 Coal Plant Achieves Goal of Capturing 4 ...

· expectations—90% carbon capture rate and an 85% capacity factor—was almost overlooked by the owners and in the coverage of Petra Nova's demise. That has left Boundary Dam 3 in Canada as the only project capturing CO 2 from a coal plant. On March 31, SaskPower (Boundary Dam 3's owner) noted that the project had captured a total of 4 million metric tons of CO 2 and claimed this .

Coal Mining and Production

Beneficiation plants produce large volumes of tailings and solid wastes. Storage and handling of coal generates dust at rates of as much as 3 kilograms per metric ton (kg/t) of coal mined, with the ambient dust concentration ranging from 10 to 300 micrograms per cubic meter ( µg/ m3)above the background level at the mine site.

Coal | 2021 Data | 2022 Forecast | Historical ...

GC Newcastle coal futures rose to 150 per metric ton, after a massive selloff that pushed the commodity almost 50% below its record level of reached on October 5th, on the prospect of higher demand for power and heating caused by colderthannormal temperatures for much of China through midNovember. Yet, the cost of coal remains close to 3month lows as China stepped up .

Estimating carbon dioxide emissions from coal plants ...

· A plant that was 100 percent efficient at converting all its coal energy into electrical energy would have a heat rate of 860 kcal/kWh or 3412 Btu/kWh; of course, it is not possible for such a plant to exist. The higher the heat rate, the lower a plant's efficiency. Heat rate is determined by the type of combustion technology, the type of coal, and the size of the plant. Additional factors ...

Great Plains Synfuels Plant |

The plant currently consumes more than 6 million tons of coal to produce 54 billion standard cubic feet (scf) of SNG annually. The plant has more than 25 years of successful operation. Along the way, changes have been made to improve productivity, efficiency and the plant's effect on the environment. Some examples of elements of the original design that were modified during the course of ...

Moving the Coal Through a CoalFired Power Plant

· Every year billion tons of coal are burned in the, with 90% of that being used for electricity generation. Several years ago, a University of Illinois professor reported that to produce 109 kWh/year of power, a plant burns 14,000 tons of coal every day. He noted that the coal that goes to a typical coalfired power plant is crushed to approximately 5 cm in size before it is loaded ...

ITP Mining: Water Use in Industries of the Future: Mining ...

per ton of coal produced. In addition, small amounts of magnesium chloride solution (~ gallon of solution per ton of coal) and calcium chloride (~ gallons solution per ton of coal) were used to retain moisture, since both these salts are hygroscopic (take moisture from the .

Estimate Jaw Crusher Capacity

· Metallurgical ContentCapacities and Horsepower of Jaw Crusher (tons/hr)Capacities of a Gyratory Crushers (tons/hr)Typical Capacities of TwinRoll Crushers (tons/hr)Typical Capacities of Cone CrushersTypical Capacities of Hammermills Example capacity calculation of a 10″ x 20″ (250 mm x 500 mm): Pp = 2800 ( SG) e = (halfway between dolomite and sandstone) A = 250/1000 x .

Belt Weigher

These scale determines the rate at which material travels on a conveyor belt over a specific period of time. Conveyor Belt Scale or Belt Weigher Working Principle A typical conveyor belt scale or belt weigher system has a weigh bridge structure supported on load cells .

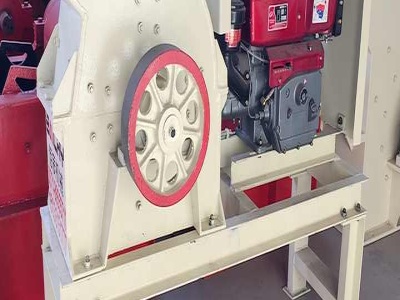

Industrial Solutions Jaw crushers

plants. The singletoggle jaw crusher with the largest antifriction bearings and highest flywheel energy 1) with new crushing elements 2) 1,200 possible All data are intended as a guide only. The machine capacity depends on the grain dis tribution as well as the characteristics and the texture of the feed material. Binding data can be provided once the specific operating conditions ...

Thermal Power Plant

GHR =Gross Heat Rate (kcal/kWh) GCV =Gross Calorific Value (kcal/kg) ... energy consumption of mill per tonne of coal for BY and multiplying it with the difference between normalized coal consumption and coal consumption in BY, we get the increase in energy consumption. It shall be described with examples in the chapters ahead. 32 THERMAL POWER PLANT Under Perform, Achieve and Trade The ...

Mineral Processing Plant Design

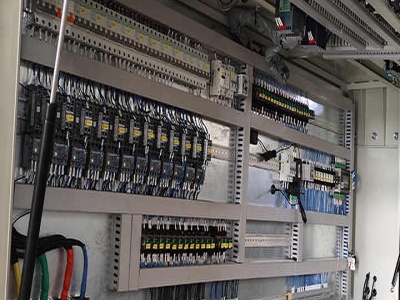

• Electronic control of crusher discharge opening and feed rate. With adjustment of a crusher's discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses). Dance, A. 2001) • More attention is being paid to the impact on crushing circuit design caused by variations in ore characteristics, size distribution ...

Latest Posts

- روسيا معدات تعدين الفحم تحت الأرض

- كسارة خرسانية مصنوعة بالمنزل

- تعدين وتصنيع الذهب التقليدي

- للبيع طاحونة قضيب معالجة الخام

- طحن الكرة المحمولة لمسحوق معادن الرمل

- المطاحن للتعدين في المملكة العربية السعودية

- الفك مختبر الشركات المصنعة محطم

- كسارة خرسانة منطقة كارديف

- آلات تكسير قشور الجوز في الصين

- آلات محطم الجرانيت في مصر

- حجر صغير محطم سعر الجهاز في نيجيريا

- دوليميت محطم في الجزائر

- ناقل الفحم في بانجارماسين

- كسارة أصغر طاحونة الحجارة والصخور

- تسبب كسارة الفك

- Om Track Mobile Stone Crushers

- Trituradores De Doble Eje Para Madera

- Cbr Test For Crusher Run Malaysia

- Sand Washing Plant Sale Supplier

- Equipment Molybdenum Grinding

- Granite Crushing Cost Estimate South West England

- Used Poultry Feed Mill

- Karakteristik Ball Mill Limestone

- Mobile Crushers Roll

- Mosaic Tiles In Johor

- Ball Mill Grinding Youtube

- Gyratory Rock Mining

- Machines For Quartz Mineral Processing

- Materials For Jaw Crusher In Europe

- Extec Labpol Automatic Grinder Polisher Price