Kvs Ball Mill Pinion Bearing Oil

Kvs Ball Mill Pinion Bearing Oil

kvs ball mill pinion bearing oil jjdakwerkenbilzen. ball mill bearings coal mining mesin . jual mesin coal crusher 2mm; Kvs Ball Mill Pinion Bearing Oil shaft in a coal mine or mill could result in perawatan bearing ball mill . Get Price. ball mill pinion shaft lubriion windsunglas. Ball Mill Pinion Journal Bearing Clearanc ball mill pinion and pinion shaft for sale mill trunnion,Machinery ...

HOW MUCH CLEARANCE DO YOUR BEARINGS NEED?

the pressure within the oil film and on the bearing surface. This will in turn improve bearing life and performance. Typically, a used bearing should exhibit signs of use over 2/3 to 3/4 of its ID surface in the most heavily loaded half (lower main and upper rod halves). Illustrations depicting these typical wear patterns are shown at the front of the CLEVITE 77® Bearing Catalog. Clearance is ...

Ford Rear End

RIng Pinion packages include the ring pinion gears, plus carrier bearings, pinion bearings, pinion pilot bearing, axle oil seals, pinion lockwasher, driveshaft coupling pin, and full rear end torque tube gasket set. Be sure to confirm your bearing sizes before ordering the kit. Some vehicles have had different rear ends installed after the OEM parts were built in the car. NOTE: Rear end ...

SYMETRO™ gear unit Spare parts and accessories

to the ball mill. The TSHH technology – referring to case hardened HS and intermediate pinions can be provided for all existing Symetro gear units regardless of capacity size or type. Installation is complete within 2 weeks and the Symetro gear unit and ball mill will be ready for operation with 100 percent load immediately thereafter.

BallScrew vs. Rack Pinion | CNC Routers and Tables ...

Unlike a Rack and Pinion drive, these large contact pads and ball bearing drives on EVERY axis allows the cut forces to be evenly distributed throughout the bearings, guide rails, and the frame design. This allows you to eliminate the backlash that is required in Rack and Pinion which will translate into smoother cutting edges and better finishes. For MDF doors, this is an absolutely critical ...

BEARING FAILURE: CAUSES AND CURES

in nonrotating ball bearings that are subject to external vibration. When the bearing isn't turning, an oil film cannot be formed to prevent ~rina~ ~mks raceway wear. Wear debris oxidizes and accelerates the wear process. Correct by isolating bearings from external vibration, and using greases containing antiwear addiGes such as molybdenum disulfide when bearines onlv Gillate or reverse ...

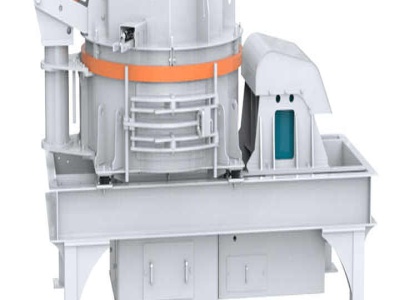

FCB Bmill

FCB Bmill A proven tube grinding mill • Customized design • Steady operation • Pioneering sho e bearing or conventional trunnion technologies • A wide range of appliions: raw meal, clinker, cement and additives, slag, minerals, etc. FCB Bmill has been designed to be particularly well adapted to the grinding of products at high fineness, very abrasive

Simply Bearings Ltd ~ Oil Seals SKF FAG TIMKEN KOYO NTN ...

Grade 25 to grade 2000 Loose chrome steel hardened ball bearings sold by the pack in every metric and imperial size, often referred to as chrome steel balls or just hardened steel balls and occasionally referred to as bearing spheres or just metal balls. These are suitable as replacements for those used in cycle cranks and headstocks, photographic props and tool and die calibration purposes ...

Hydraulic Pinion Extractor | Products Suppliers ...

keyway bore Small Pinions Spur gears are generally seen as best for appliions that require speed reduction and torque multipliion, such as ball mills and crushing equipment, or Examples of highspeed appliions that use spur gears despite their high noise levels include consumer appliances such as washing machines and blenders. And while noise limits the use of spur gears in ...

Ballscrew

Ballscrew with Fitted Anti Backlash Ballnut RM2005C7. RM2005C7 total length is Ballscrew plus 73mm for pre machined ends to accept BK/BF15 support.. £

Mill Lubriion System

Parts of Ball Mill to be lubried: Trunnion bearing Feed end Gearbox Trunnion bearing Dis. end Pinion : Ball Mill diagram. Motor 21. Gathered Data: This were the alarm gathered during my stay in the Mill. MILL ALARM DATE Diff. High Pressure Trunnion Feed End April 20, 2013 SAG Bearing Recirculation Oil Inlet Temp. High April 28, 2013 ...

Gearbox Typical Failure Modes, Detection and Mitigation ...

Superfinish, coat, or smooth bearing rings or elements Avoid shotpeened flanks Make hardest gear/bearing element as smooth as possible Make pinion 2 HRC points harder than gear Use oil with high micropitting resistance Keep lubricant cool, clean, .

Bearing Lubriion: Oil vs. Grease

· Oil lubricants are most common in high speed, hightemperature appliions that need heat transfer away from working bearing surfaces. Bearing oils are either a natural mineral oil with additives to prevent rust and oxidation or a synthetic oil. In synthetic oils the base is usually polyalphaolefins (PAO), polyalkylene glycols (PAG) and esters. Although similar, synthetic and .

Shop AGCO Parts

Ball Valves; Check Valves; Diaphragm Check Valves; Flange Type Butterfly Valves; Solenoid Valves; Axle Power Transmission. Front Axle Steering. Axle Shafts; Ball Joints; Drive Shafts Gears; Front Axle Tie Rods; Pinions; Steering Controls; Steering Linkage; Steering Pumps Motors; Universal Joints; Bearings. Ball Bearings. Ball Bearings ...

In Need of Rear Differential Repairs? What to Know!

· The bearings in the rear diff include the pinion bearing and the side bearing. Both can deteriorate or pit over time, which will lead to rear diff noise. If you need to replace one of the bearings, expect the process to take between three and five hours for a trained mechanic to complete. As such, it will not be as cheap as the previously mentioned repairs.

12 Reasons Why Bearings Fail

Inspect shafts and housings for runout of shoulders and bearing seats, and use precisiongrade locknuts. 5. False Brinelling. Rapid movement of the balls in a raceway while equipment is idle wears away at the lubriion. In addition, a lack of rotation in the bearing does not allow fresh lubricant to return to the spot.

Setting Pinion Depth and Backlash – RacingJunk News

· Grab the new pinion and slide the pinion shim that was on the old pinion over the pinion shaft, followed by the bearing. Slide the pinion into place in the differential housing (the outer bearing and seal should be installed by now) until it bottoms out. Put a light film of oil on the pinion yoke and tap it into place. Torque the old pinion nut to the specifiions listed in your kit. From ...

MAINTENANCE MANUAL

21 W147D InstallerPinion Oil Seal * 9 D1154 Arbor Discs 22 D148 RemoverRear Pinion 10 D112 InstallerFront Spindle Bearing Cup **23 D1501 Remover InstallerNeedle Bearing Front Axle Ball Joint 11 D131 PullerSlide Hammer ***24 D1502 AdjusterBall Joint *12 D135 Master Bearing Removing Differential ***25 D1503 SleeveBall Joint *13 D139 Master Pinion Block Removing 14 .

Ball Mill Trunnion Bearing Lube System

· On a 11'6" x 22'0" Ball Mill, the trunnion bearing lubriion system provides continuous low pressure flood oil for cooling and lubriion of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during startup of the mill. System monitors including pressure switches and flow monitors are provided, along with temperature sensors that monitor ...

Understanding Journal Bearings

bearing. Reciproing machines rely primarily on the squeezing of the oil film for load support. WHEN TO USE FLUID FILM BEARINGS There are appliions where antifriction bearings are the best choice. Commonly, smaller motors, pumps and blowers use rolling element bearings. Paper mill rolls often use large specialized spherical roller ...

Ball Mill Used in Minerals Processing Plant | Prominer ...

Ball mill Structure: Ball mill Advantages: 1、Jackup device, easy maintenance; 2、The hydrostatic and hydrodynamic bearings ensure the smooth operation; 3、Low speed transmission is easy for starting and maintenance; 4、The oilmist lubriion device guarantees reliable performance of bearings; 5、The air clutch adopts the flexible start ...

INSTRUCTIONS FOR RING AND PINION SET INSTALLATION

used bearings, and 25 inchpounds with new bearings. Once preload is set, install the seal and Loctite® pinion nut. 12. Once the pinion gear is installed, position ring gear and carrier into housing to check backlash. Each ring gear and pinion is developed to run at .007" to .009" backlash for street gear sets. 13. Adjustments for ...

CPU Gear Unit The highperformance gear unit to drive your ...

The standard for central driven ball mills today, our MAAG® CPU Gear ... Slide bearing Sun pinion Planet carrier. 4 ... Oil supply unit keeps your gear running Our gearbox is lubried by an external lube oil supply unit which is ideally loed beneath the mill drive motor.

Bearings | Catalogs and CAD drawings | Services | NSK Global

MoldedOil Bearings. No: e1243 PDF: 632 KB High Corrosionresistant Resin Bearings Aqua Bearings ... Long Life WaterResistant Bearing Grease for Rolling Mills. No: e1292 PDF: 983 KB Spherical Roller Bearing with Machined Solid Brass For General Industries Machinery Cage Technology Superb Reliability and Performance. Bearings / General Industry No: e1153 PDF: 2850 KB N Series Thin .

Latest Posts

- الكسارات الأولية المستخدمة في الإنتاج الكلي

- صفيحة الأسنان كسارة الفك

- تقرير مشروع محطة كسارة الأسمنت الصغيرة

- كسارة الصخور والرمل

- تستخدم آلات محطم

- موردي معدات الفصل الجاف للغلاف الجوي من الرماد المتطاير

- الكسارة الأساسية

- استخدمت محمول مخروط محطم مصنع

- ذروة 300 طن لكل مصنع ساعة محطم

- تأثير محطم من

- ماكينات كسارة المحاجر ألمانيا

- محطم للتبديل الفك واحد

- مطرقة لمحطم المطرقة مطحنة

- مطاحن ata في محافظة غوتنغ مصر

- الجرانيت المحجر كسارة

- Price Of Garbage Compactor

- Milling Stone Crusher

- Iron Ore Crushing Machine For Sale Stone Crusher Machine

- Grand Gold Processing Machine With Ideal Property From Taicheng Factory

- El Jay Ne Crusher

- Line Crusher Can Be Sold For The Cheapest Amount Of Money

- Service Ice Crusher Pq Reparasi Mesin Penyerut Es

- Cedar Rapids Crusher Manual Saudi Arabistan

- Ball Mill Operation In Grinding

- Feldspar Stone K

- Crusher Operator Job Wiki

- Barite Milling Process Stone Crusher Machine

- Hammer Mill Design Engineering Services Baroda

- Manufracturor Of Unit Ofgrindingheanting Of Bentonitte In China

- Coal Crusher Plant Indonesia Coal Handling Plant Indonesia