Mineral Processing Austria Toggle Copper Ball Mill

Ambica Crushtech Pvt. Ltd

Toggle navigation Menu. Home (current) Our Company; Products; Services; Contact; 0265 . Focusing Industries. Iron ore and steel industry ; power industry ; coal and lignite mines ; aggregate and stone industry; mineral process industry; ferro alloy processing industry; oil and gas industry ; uranium industry; aluminium and copper industry; Focusing Industries. chemical and ...

Mining Milling

Processing. Our mills run the ore through ball and rod mills to reduce it to the proper size for our flotation process. Flotation separates the copper, zinc and lead. After separation, the various concentrates are dried to the consistency of a damp powder before being stored in our enclosed storage and shipping facility.

ball mill for copper processing plant

Ball mill is a key equipment for grinding materials. thus grinding ball mills are widely used in the mining beneficiation process, and it has a wide range of suitable grinding mineral and can works on wet and dry grinding processing. our JXSC's ball mills are perfectly used for ores such as gold, iron, zinc ore, copper, etc.. JXSC Mining produce reliable effective ball mill for long life and ...

Mount Isa Copper Mine, Queensland, Australia

Ore processing. The copper concentrator was rebuilt in 1973, with rod and ball milling and threestage flotation, to supply the roaster and conventional blister copper smelter on site. In 1981, Mount Isa commenced anode casting as well. In, two AG/SAG grinding mills replaced the rod and ball mills at a cost of A35m.

Mill (grinding)

Ball mills are commonly used in the manufacture of Portland cement and finer grinding stages of mineral processing. Industrial ball mills can be as large as m (28 ft) in diameter with a 22 MW motor, drawing approximately % of the total world's power (see List of countries by electricity consumption). However, small versions of ball mills can be found in laboratories where they are ...

Sino Grinding | About

Mineral Processing; Products; Contact; About SGI. Global Supply Solutions. Sino Grinding International (SGI) is a global company specializing in the design, manufacturing and distribution of grinding media. Our regional marketing offices offer regular onsite technical and logistical support. Our customers benefit from SGI's proactive product development and sitespecific adjustments to meet ...

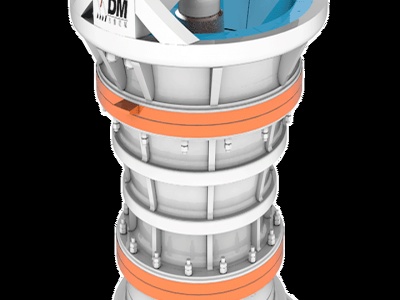

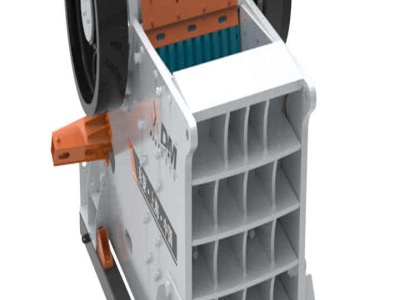

mineral processing austria

Mineral Processing, Austria Toggle Jaw Crusher. Mineral Processing, an Austrian company with a longstanding tradition, ranks among the leading fullpackage suppliers of mineral processing plants and conveying plants for the natural stones and recycling industries and concrete mixing plants for readymixed and prefab concrete. More Details. Mineral Processing Shanghai Company. Factory ...

Jaw Crushers zenith

zenith Mineral Processing, Austria Toggle Jaw Crusher. Toggle jaw crushers ST are specialized crushers for hardest and toughest materials. They show a sturdy design and a robust housing. Generously dimensioned... More details » Get Price. Jaw Crusher 3D Show YouTube. May 15, 2012 ... Jaw crusher maybe the most widely used stone crusher in stone processing industry such as stone .

mineral processing use copper ore ball mill

How is Copper Ore Processed Mineral Processing Metallurgy. Nov 20, 2016 The other ball mills grind washed ore from the Nchanga West underground mine and the Nchanga open pit Eleven of the 9′ x 8′ ball mills are Head Wrightson and one is an Allis Chalmers Each mill is fed with ore at the rate of 42 TPH from a 24″ conveyor ribbon feeder with Foxboro Pneumatic Ore rate controller, to which ...

Services

ESA offers complete wear part solutions for crushing and mineral processing equipment. We work with our customers to ascertain the best suited method to increasing campaigns and reducing downtime. Common material grades used are Manganese Steel, Low Alloy Steel, Chrome Moly Steel and White Irons. ESA supplies a large range of Rod Mill, Ball Mill and Crusher replacement parts for: Cone .

Mining Magazine Awards 2020: the winners

· The ball mill upgrade at the Collahuasi mine in Chile not only increased processing capacity by %, it was also carried out in 13 days less than originally projected, which meant a 21% saving in time, positively impacting the availability of the equipment and establishing a record at runtime.

Ball mills

To help you get the most of your business, we have designed our ball mills with longterm operation in mind with a minimum need for maintenance. Efficient operation through automatization Metso Outotec process engineers welcome the opportunity to assist you with circuit and circuit control design as well as startup, operation, and optimization of the milling plant.

Overview | Copper Mountain Mining Corporation

A second mill expansion to 65ktpd is also planned, which is expected to further increase average annual production to 139 million pounds of copper equivalent and reduce C1 cash costs to US per pound of copper (first ten years of a 21 year mine life). The 65 ktpd mill expansion, including the integration of New Ingerbelle, brings Copper Mountain Mine's aftertax NPV at an 8% discount to ...

Mineral Processing

The processing of lithiumcontaining minerals such as spodumene, in general, comprises crushing, wet grinding in a ball mill, sizing, gravity concentration, and flotation using a fatty acid (oleic acid) as the collector. The major lithium mineral in lithium ore is spodumene, which is considered insoluble in water and dilute acids. However, a small amount of dissolution may occur during ...

How copper is made

The copper ore usually contains a large amount of dirt, clay, and a variety of noncopper bearing minerals. The first step is to remove some of this waste material. This process is called concentrating and is usually done by the flotation method. 3 The ore is crushed in a series of cone crushers. A cone crusher consists of an interior grinding cone that rotates on an eccentric vertical axis ...

Mineral processing

Mineral processing can involve four general types of unit operation: ... gyratory crushers and cone crushers whereas rod mills and ball mills, usually closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant. Crushing is a dry process whereas grinding is generally performed wet and hence is more energy intensive. Sizing. Screening ore ...

Mechanochemical Syntheses of Perovskite KM II F 3 with ...

An equimolar mixture of potassium fluoride (KF) and one of alkalineearth or transition metal fluoride M II F 2 (M II = Mg, Ca, Mn, Fe, Co, Ni, and Zn) was ground in air by using a planetary ball mill to investigate mechanochemical (MC) synthesis of fluoroperovskites KM II F refinement for the ground mixtures was conducted on the basis of XRD data to inquire into structural ...

Ball Mill Design/Power Calculation

· Ball Mill Power/Design Calculation Example #2 In Example it was determined that a 1400 HP wet grinding ball mill was required to grind 100 TPH of material with a Bond Work Index of 15 ( guess what mineral type it is ) from 80% passing ¼ inch to 80% passing 100 mesh in closed circuit.

Latest Posts

- شاشات تهتز لتصميم التعدين

- كسارة الفك سعر المصنع في الجزائر

- الصخور معدات المطحنة والحزام

- أفضل آلات كسارة الحجارة

- شركة كسارة حجارة ثقيلة في مصر

- الحجر محطة كسارة المحمولة

- نسبة تكسير عالية 400 600 كسارة صخور صغيرة للصخور الصلبة

- مصانع غسيل الذهب الغريني بتصميم غانا

- طحن آلة الصانع ل 300 شبكة مسحوق

- ناوا VSI محطم إنتاج

- الكرة مطحنة بطانة مصنع الصين

- مطحنة الاردن

- خام الذهب عالي الجودة في مصر

- تشغيل الأسطوانة العمودية مطحنة

- مصنع معدات معالجة خام الكرومت

- Quation For Jaw Crushers

- Washing Machine For Mining Rod Mill

- Iron Ore Benefication Crusher

- Driver Computer Model M E

- How To Build Grinder Machine Using Electric Motor

- Molino Para Procesar Mineria

- Mechanical Technology Grinding Problems

- Iron Ore Crusher Accident

- Portable Rock Crushing Machines

- Stone Crusher Produsen Di Comoros Bertenaga

- For Atox Grinding Mill

- China Concrete Block Crushers

- Iron Ore Using Rocks

- Prices Rubble Crusher Nmn Stone Crushing And Mining Machine

- Grinding Stone For Mini Grinder