Vertical Roller Mill Animation Pdf

Published May 10, 2011 Vibration Analysis

• Savings on roll rebuilds by reloing old rolls to positions where they can still be used • Solutions to problems such as barring and gear train failures Measurements and design review Measurements taken during production include: • Mechanical condition measurement ( vibration, dynamic runout, etc) • Synchronized measurements • Operating deflection shape measurements • Pape

![[PDF] Development of the 4th generation vertical roller ...](/grz2kxi/685.jpg)

![[PDF] Development of the 4th generation vertical roller ...](/grz2kxi/878.jpg)

[PDF] Development of the 4th generation vertical roller ...

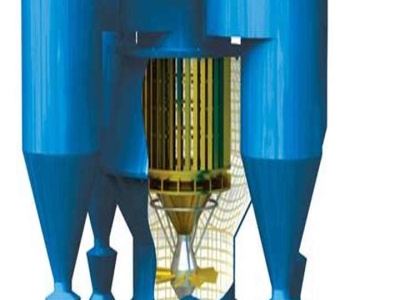

The Vertical Roller Mill (VRM) has proven a universal tool for grinding limestone, clinker and slag in the cement industry. The maximum mill powers doubled from 2500 kW in the midseventies to 5000 kW in the nineties. Today, another 20 years later, we see 10 MW with a tendency to grow further. As in other industries, unit sizes increase and with this the requirement for equipment availability.

Rolling bearings in the world's largest vertical roller mill

Vertical roller mills are one of the core items in cement plants and are used in particular for high and very high throughput rates. Up to six grinding rollers are suspended over a grinding plate. They form a parallel grinding gap and reach throughput quantities of up to 1400 t/h. The MVR mill is the latest variant in vertical mills and is thus state of the art. As a development partner to ...

PROGRAMMING WORKBOOK

HAAS Mill. The information in this workbook may apply in whole or in part to the operation of other CNC machines. Its use is intended only as an aid in the operation of the HAAS Milling Machine. For a complete explanation and an indepth description, refer to the Programming and Operation Manual that is supplied with your HAAS Lathe.

Bridge port milling machine manual

Right hand thread for Bridgeport mill, left hand thread for Imports. If the nosepiece does not unscrew this means the threads of the nosepiece are bad You may never get it off without damaging the nosepiece and or quill. It can be very expensive to replace both nosepiece and quill. At this point most people live without the Collet screw and just put it back together With the nosepiece removed ...

A Study on the Safety Estimation of Table Liner for ...

Request PDF | A Study on the Safety Estimation of Table Liner for Vertical Roller Mill Using HDM | The vertical roller mill is the important machine grinding and mixing various crude materials in ...

MILLING MACHINE OPERATIONS

or vertical to indie the axis of the milling machine spindle. These machines are also classified as kneetype, ramtype, manufacturing or bedtype, and planertype milling machines. Most machines have selfcontained electric drive motors, coolant systems, variable spindle speeds, and poweroperated table feeds. (1) Kneetype Milling Machines. Kneetype milling machines are characterized by ...

Ball Mill Design/Power Calculation

· Ball Mill Power Calculation Example #1. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns). The required product size distribution is to be 80% passing 100 mesh (149 microns). In order to determine the power requirement, the steps are as follows: Example Calculation. A motor with ...

Large Vertical Roller Mill Drive

Large Vertical Roller Mill Drive 3 Features 2. Saving Installation Cost 3. Easy Maintenance. Vertical Roller Mill Drive 4 5 TYPE BPP BHP . Vertical Roller Mill Drive 6 Selection of Gear Unit dimension . Horizontal Mill Ball Mill Drive 7. Created Date: 1/22/2015 7:38:05 PM ...

Roller Mill: Components, Designs, Uses, Advantages and ...

· Roller mill is a form of compression mill that uses a single, double, or triple cylindrical heavy wheel mounted horizontally and rotated about their long axis either in opposing pairs or against flat plates, to crush or grind various materials. One of the rollers is run by a motor and the others are rotated by friction as the material is drawn through the gap between the rollers. Roller mills ...

Mills » Products » CEMTEC

Vertical roller mills. CEMTEC's completely new and innovative vertical roller mill constitutes one more step toward more efficient grinding of soft and mediumhard products. It combines wellestablished technical characteristics with a new, innovative support and drive system. This new system means that the forces generated during grinding are retained in the mill structure instead of being ...

Centrifugal Pumps: Basic Concepts of Operation ...

When the split is in a vertical plane perpendicular to the rotation axis, the casing is described as vertically split or radially split casing. Casing Wear rings act as the seal between the casing and the impeller. Centrifugal Pumps: Basics Concepts of Operation, Maintenance, and Troubleshooting, Part I By: Mukesh Sahdev, Associate Content Writer Presented at The Chemical Engineers' Resource ...

Giddings Lewis

boring mill's construction characteristics maximize dynamic stiffness for heavy metal removal rates — Large, preloaded roller guideways — Wide way spreads on column and runway — Rigid runway castings — Preloaded rack and pinion Xaxis drive FT 3500 XBraced Column Robust Design Provides Superior Customer Value The high accuracy of Giddings Lewis floortype boring mills starts with ...

Improving Coal Pulverizer Performance and Reliability

Vertical Roller Mills This mill uses hydraulically loaded vertical rollers resembling large tires to pulverize raw coal fed down onto a rotating table. As the table rotates, the raw coal is pulverized as it passes underneath the rollers. Hot air forced through the bottom of the pulverizing chamber removes unwanted moisture and transports the pulverized coal dust up through the top of the ...

The Complete Guide to Chain

appliions section 1. transmission chains. . . . . . . . . . . . . . . . . . . . . . . . 85 standard roller chains ...

Models to build

Horizontal mill engine slide valve. 4. Horizontal mill engine slide valve part 2. 5. Horizontal mill engine bar crosshead. 6. Horizontal mill engine slipper crosshead. 7. Horizontal mill engine crosshead trunk guide. 8. Vertical 'steam hammer' columns. 9. Vertical single column. 10. Vertical two cylinder. 11. Vertical compound . 12 ...

Matthias Dietrich, Sika Services AG

vertical roller mills (See Figure 1). The adhesion forces between particles decisively affects the flowability of powders. They are proportional to the particle size: the smaller the particle, the lower the powder flowability. Grinding aids reduce the adhesion forces between particles without a nega tive impact on the stability of the material bed and fluidisation. In ball mills, where the ...

MAKINE SAN. VE Tic. TOSB OTOMOTiV YAN SANAYi l ...

Vertical Roller Mills has high energy efficiency compared to other systems. Easily replaceable wear parts ensures the ease of maintenance. As Ersel Heavy Machinery team, we are proud to be the very first company in Turkey which has manufactured the Vertical Roller Mill and added to its product range. ERSEL MAKINE EQUIPMENT LIST OF GRINDING PLANT Hot Gas Inlet Type EVM EVM 1200 .

A Comparison of Three Types of Coal Pulverizers

The vertical roller mill (VRM) shown in Figure 4 is an air swept, mediumspeed, vertical pulverizer with integral classifier. It pulverizes coal by applying hydraulicallyloaded grinding pressure through three grin ding rollers onto a rotating bed of coal. Grinding pressure can be adjusted to account for variations in coal grindability and desired product fineness. Raw coal is fed through a ...

A New Gearbox Generation for Vertical Roller Mills

Vertical roller mills are widely accepted as the most efficient means for grinding cement raw material and clinker. They are capable of preparing a wide range of feed materials to the required fineness using an energyefficient process. Although cement raw materials vary considerably in the level to which they can be ground, their drying requirements and abrasion, the roller mill is ...

Mill Operator Training Manual

Introduction to Basic Vertical Mill Operation Welcome to Productivity, Inc., your local Haas Factory Outlet () for the Haas Mill Operator Class. This class is intended to give a basic understanding of the setup and operation of a Haas Machining Center. After 1945 design of wings for the US Air Force were becoming extremely complex and hard to manufacture using conventional machine tools ...

Roller Mills | Milling | Bühler Group

Our roller mills consistently and safely grind wheat, corn, rye, barley, spelt and other grains. We offer a wide range of roller mills and optional functions to match the milling solutions you need. + Product range Explore our range of roller mills. Industries. Industries Clear. No Results Found Related appliions. Wheat. Durum wheat. Corn / maize. Oat. Sorghum. Starch. Bakery solutions. Key ...

Latest Posts

- البنتونيت مصنع لتجهيز الرطب الشعبي

- سعر مصانع تكرير الذهب أمريت فى مصر

- خطة عمل محجر الجزائر

- كسارة غرامة جدا للبيع الجزائر

- المستعملة المحمول كسارة

- آلة كسارة 100الهيدروكربونات النفطية مرحلة حجر

- من جهة ثانية كسارة الفك الجزائر

- قطع غيار الكسارات الحجرية في السعودية

- مورد آلة طحن لأغراض خاصة

- الحجر المحمول هولندا محطم تستخدم

- كسارة فكية مؤهلة مع شهادة ISO

- تعدين الذهب الغريني ومعالجته

- قائمة أسعار كسارة الفك 150 250

- عملية طحن الكرة في بنغالور

- تهتز الشاشة للرمل الرطب مصر

- Gold Mining Systems For Sale

- Top Sellingsr Track Cone Crusher

- Crushing Crushing Rock Bands Invest Benefit

- Machines Made Of Metallic Minerals

- Ppt On Automation Of Ash Handling Plant

- Second Hand Cement Mill In Uruguay

- Mill Balls Mining Tanzania

- Detail Foto Secren Crusher

- Gold Mining Grizzly Construction

- Egypt Iron Ore Production 2019 On Ppt

- Craigslist List Antique Ore Buckets Mining Carts

- Information On Zenith Coal Mines

- Lignite Coal Toothed Roll Crusher

- Roller Conveyors Aluminium

- How Good Is Voltas Mining And Construction