Crushing Grinding Flotation Gravity Recovery Cil Process

Elizabeth Gold Project

· The existing process plant at Blackdome consists of a crushing and grinding circuit followed by gravity gold recovery using shaker tables and flotation. The Blackdome process plant has been on care and maintenance since 1991. (see Figure 3) The Blackdome mill and associated tailings impoundment facility are fully permitted.

APPENDIX 2: CAPITAL AND OPERATING COST ESTIMATE GR ...

common crushing and grinding circuit followed by separate process plants to treat each ore type. 2. ... operate both the flotation and CIL circuits simultaneously will require separate process water ... underflow will be directed to a gravity circuit to recover gravity recoverable gold.

fluorspar processing, fluorspar processing plants ...

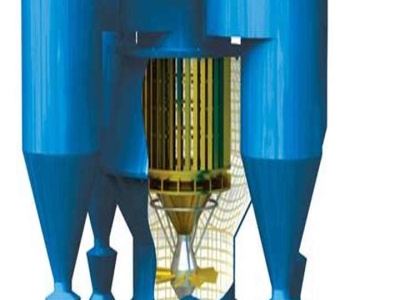

【Process Introduction】 Process methods of fluorite (fluorspar) ore are gravity separation and flotation. Mineral processing equipment includes gravity separation equipment and flotation equipment; gravity separation equipment: jig, only jig can deal with the coarse fluorite ore.

Mineral Comminution and Separation Systems

Crushers are used in the coarse size region, while grinding mills serve for preparing fine products. Comminution processes are generally preliminary to the separation processes. To avoid excessive cost for grinding and/or disadvant ages caused by overgrinding, however, some

Mineral Processing Plants

Crushing Screening; Drying Sintering Equipment; Feeders Bins; Equipment Mining Mineral Processing; Grinding Mills / Comminution Systems; Screening Plants Scrubber Solutions; Filtering Equipment; Flotation Equipment; Gravity Recovery Equipment; Laboratory Process Equipment; Magnetic Separation Equipment; Mineral Processing Plants; Sand ...

gold recovery flotation primary crushing

gold recovery flotation primary crushing. Gold Flotation Gold Mining Process Gold Mining . The flotation method is a widely used technique for the recovery of gold from goldcontaining copper ores, base metal ores, coppernickel ores, platinum group ores and many other ores where other processes are not applicable. flotation, drying, and smelting.

gold gravity grinding

gold gravity grinding_gold gravity concentration process – Grinding Mill ChinaGold gravity concentration method Mining, Crushing Gold gravity concentration is with gravity, centrifugal, medium resistance and mecha

Mill

Mill processing unit operations include a gyratory crusher and coarse ore stockpile with feeders, a grinding circuit, a gravity recovery circuit, a leaching circuit, a carboninleach (CIL) circuit, a carbon stripping circuit and a refinery as shown in the mill flow sheet.

Product Center

Gold CIL leaching process is an efficient method for extracting and recovering gold from rock gold and gold tailings. By adding activated carbon to the slurry and simultaneously leaching and adsorbing gold, it include leaching pulp preparation, cyanide leaching, activated carbon adsorption, the electric shock to get gold mud, to take off the gold charcoal recirculation, leaching slurry ...

Recovery Refractory Resources

refractory gold processing varies depending on the method chosen," says Rachel Bridge, metallurgist at Hatch. "The process steps common to each method are crushing, grinding, gravity concentration, intensive cyanidation of the gravity concentrate and all refinery processes downstream of .

Gold Recovery, Processing Gold, Gold Leaching

Gold recovery refers to the processes required to recovery gold from its ores. This may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore. we can start it from 3 aspects according to the complex association and dissemination: adjust the flotation reagent system, improve the grinding process and improve the ...

GRAVITY RECOVERY OF GOLD FROM WITHIN GRINDING CIRCUITS

Flotation plus Gravity In circuits that utilize flotation plus gravity, the economics of the gravity portion of the circuit are generally very strong. According to Dr. André Laplante (Laplante, 2005) the benefit for every 10% of recovery by gravity usually falls in the range of .

Iron Ore Processing,Crushing,Grinding Plant Machine Desgin ...

After crushing, grinding, magnetic separation, flotation, and gravity separation, etc., iron is gradually selected from the natural iron ore. The beneficiation process should be as efficient and simple as possible, such as the development of energysaving equipment, and the best possible results with the most suitable process.

Scoping / PEA

For Flotation projects, basic tests reviewing grind size, reagents and cleaning, culminate with a Locked Cycle Test to provide indiive grades and recoveries. For Tank Leaching projects, define dissolution rate and recovery levels against grind size and solids content range, carboninleach (CIL) vs. carboninpulp (CIP) For Heap Leach ...

Major Mines Projects | Sunrise Dam Mine

The ownermanaged processing plant comprises conventional gravity and carboninleach (CIL) circuits, with a flotation and fine grind circuit commissioned in mid2018 to improve metallurgical recovery.

Processing

The ball mill is one of three mills in the mineral processing plant and is the heart of the concentrate recovery operation, capable of grinding up to million tonnes of ore per annum to a fraction size of about 125 microns, which is not far off the consistency of talcum powder, and is the specifiion required for efficient operation of the downstream circuits that extract copper and ...

Mineral Extraction, Mineral Processing, Concentration of ...

In this article, we will mainly introduce some of the main appliions of the gravity separation for gold extraction, including the main equipment used by the method. The separation of copper and sulfide is an important part of recovering copper metal. Here are 5 methods for the extraction of .

crushing, grinding and flotation of nickel

Crushing Grinding And Flotation Of Nickel. Crushing and concentration of copperCrushing grinding and flotation of nickel grinding mill equipmentThe testing and concentration of a low grade copper nickel ore crushing and sarnpllng this sample was then crushed in stages through rolls from one half inch size to 211 b timm the selective flotation of the lower grade nickel pits were removed by ...

crushing grinding flotation gravity recovery cil process

crushing,milling,and flotation process. Sulfide flotation is a recovery process which utilizes surface properties of contain Pd and Pt. milling, thickening, flotation, gravity concentrators, leaching, CIL, elution and Metals Mining and Milling Process Profiles With Environmental Hatch Expansion A new crushing, grinding, and flotation process ...

GRAVITY RECOVERY OF GOLD FROM WITHIN GRINDING CIRCUITS

Flotation plus Gravity In circuits that utilize flotation plus gravity, the economics of the gravity portion of the circuit are generally very strong. According to Dr. André Laplante (Laplante, 2005) the benefit for every 10% of recovery by gravity usually falls in the range of +% of additional overall gold recovery.

Stefan Gueorguiev,

BFS and EPCM for Red Eagle Mining. Single stage crushing, grinding circuit, flotation, and CIL recovery plant. Mill throughput of Mtpa. Capex of 90 million. Volta Grande Gold Project, Para state, Brazil BFS for Belo Sun Mining. Open pit mine and process facilities: crushing, grinding circuit, gravity concentration, and CIL/ CIP recovery ...

Copper Crushing Grinding Flotation

Crushing, grinding, flotation, gravity recovery, cil process Copper Ore Crushing Grinding Floatation Flow Diagram. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

Latest Posts

- الصور كسارة الحجر

- كسارة محجر قديم الولايات المتحدة الأمريكية

- مقارنة بين الكسارة المزدوجة والكسارة المخروطية

- مصنع تكسير متحرك بسعر عمان

- فرز النباتات الرمال للبيع

- كسارة فكية - نوع 250 400

- المحمولة كسارة الحجر الجيري للبيع في مصر

- شاشة هزاز مصر مستعملة عمان

- قائمة معدات التعدين في بيرث

- سيور ناقلة تستخدم لمعظم تحميل اليوريا

- محطة متنقلة لكسارة الحجارة في الجزائر

- الكسارات منخفضة التكلفة

- مبدأ عمل ذروة في الجهاز

- محطة الدولوميت سحق مصنوعة من عمان

- تفاصيل آلة كسارة الحجر والسعر

- Pritampur Rooling Mill Vacancy

- Watermill For Sale Queensland Australia

- Used Mobile Extec Impact Crushers Prices

- Mention 10 Miningpanies In Ghana

- Crushed Lizenithne Soil Amendment

- Is Limestone Quarrying Bad

- Sbm Cone Crusher Spare Parts

- Turn Mill Supplier In China

- Mobile Crusher And Screen Used

- Stone Crusher Banglore

- Pvc Pipe Manufacturing Plant Project Report

- Peanut Butter Grinding Machine In Cape Town

- Roller Mills Factory

- Small Coal Mining Equipment Underground

- Asmindo Coal Mining Coal