Mineral Beneficiation Flotation Process Iron Ore In Reagent

Genera Processing Technology For Minerals | Prominer ...

Flotation is a typical mineral ore processing method based on the difference of the physical and chemical property and floatability between valuable minerals and veins. Technically, flotation can be used in almost all of the mineral separation. It is especially efficient to process metal and nonmetal minerals like copper, pyrite, iron, gold ...

Phosphate Beneficiation

Flotation separates valuable minerals (copper, lead, zinc, iron, and phosphate too) from the contaminating minerals in the ore (sand in this case). In the direct flotation process the valuable mineral is coated with a special hydrocarbon (fatty acid) that makes coated particles behave the same as .

Iron Ore Processing Project – Delta Minerals

Iron Ore Processing Project ... little and inhibit much more cost saving Strong magnetic Process recycles fine iron minerals which can play a dual role of des and tailings out creating good conditions for flotation. Reverse flotation Process system is simple which can significantly reduce the flotation reagents into pulp and decrease the ...

Role of Surfactants in Mineral Processing: An Overview ...

Nov 10, 2018 · Depletion of highgrade resources has necessitated the use of lowgrade fines, which contain good amount of mineral values and also liberate in finer sizes. Froth flotation, a physicochemical surfacebased process, is the most established solution, both technologically and economically, compared to other alternatives for fines beneficiation. For a successful and effective flotation ...

Hematite (Lowmagnetic) Dressing Plant ...

Hematite(week magnetic ore) is refractory minerals. Before, the flotation and roastingmagnetic separating process are mainly used. For the past few years, due to the appliion of strong magnetic separator, undersize sieve etc new equipment and gravity separation equipment, reverse flotation process, hematite (week magnetic ore) dressing have got remarkable effect.,It is a high technological ...

CSIRNML

The Mineral Beneficiation Group is engaged in R D in beneficiation of low grade ores and minerals. It has developed expertise and facilities towards carrying out studies on development of process flowsheets for beneficiation of low and lean grade ferrous, nonferrous, nonmetallic, industrial, refractory, strategic, fertilizer minerals, precious metals, coals and mine/industrial wastes.

extraction of iron, process of iron, iron processing, iron ...

iron ore slurry is pumped to the agitation tank. This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore (~ mm) going to froth flotation cells for recovery of iron. magnetite processing plant,the process of flotation separation is replaced by magnetic separation.

Guides

Apr 23, 2020 · The Guide of Flotation Defoamers. Flotation agents are chemical agents used in the mineral flotation process which can adjust the surface properties of the minerals, increase or decrease the floatability of the minerals, and make the pulp properties and foam stability more conducive to mineral separation. Common flotation agents are collectors ...

The Beneficiation Method of Rare Earth Minerals

Oct 27, 2021 · In the beneficiation of seaside placers, weak magnetic separation is often used to separate ilmenite from monazite; strong magnetic separation can also be used to separate monazite from zircon, quartz, and other minerals. In the beneficiation of rare earth veins, in order to simplify the flotation process and save flotation reagents, sometimes ...

Beneficiation of jordanian iron ore warda north of jordan

Aug 10, 2016 · Beneficiation of Jordanian iron ore: Warda north of Jordan 15 such as silica, calcite, and other trace metals, both fatty acid and amine floation werer tested on both samples . fatty acid flotation was conducted by the CUSTOFlOT7080 while CUSTAMIN690 was used in amine flotation . 400 g of iron ore was conditined with the required dosage of ...

Flotation Separation Iron Ore

What Is Iron Ore Beneficiation with pictures. Oct 26 2019 · Iron ore mining often focuses on looking for hematite deposits known as red iron ore and magnetite as they have naturally weak magnetic fields that aid in their purifiion Hematite however responds better to the flotation process in iron ore beneficiation than magnetite so it

Froth flotation

Froth flotation is a process for selectively separating of hydrophobic materials from is used in mineral processing, paper recycling and wastewater treatment industries. Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th century.

Beneficiation of Iron Ores – IspatGuru

Apr 03, 2014 · Beneficiation of Iron Ores. Iron ore is a mineral which is used after extraction and processing for the production of iron and steel. The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron. magnetite). Ores are normally associated with unwanted gangue material. Grade of iron ore is usually determined by the total ...

iron ore beneficiation by floatation

Beneficiation of Iron Ores by pilot scale Flotation Column (M/s Sociedado De Fomento Industrial Ltd., Goa, June 2002) [71 m dia flotation column was installed at Greater Ferromet plant of M/s Fomento, Goa, to test the appliion of column flotation technology for iron ore beneficiation.

Mineral Industry News

For the flotation process, whether a mineral processing obtains the satisfactory mineral processing indexes depends largely on the flotation reagent system, the method and loion of flotation reagent added. ... we finally established two iron ore beneficiation systems, and havs experience on extraction of iron ore. ... we constantly ...

Iron Ore,Production Process of Iron Ore,Iron Ore ...

Flotation process is also commonly seen in nowadays iron ore beneficiation. It has become a very important way to recover weak magnetic ore. It is also used to treat iron ore fine to reduce the content of silica and impurities. Flotation beneficiation separates ore by different physical and chemical properties of different materials.

Mineral and Technological Features of Magnetite–Hematite ...

Apr 06, 2021 · One of the upcoming trends in the processing of ironbearing ores from the technological point is regrinding and flotation repreparation of iron ore concentrates obtained after magnetic separation. 8−15,17,18 An actual trend for the investigation of flotation of iron ores is the selection of reagent regimes. 20−22 Starch, carboxymethyl ...

iron ore flotation and reagents

Flotation Reagents For Iron Ore Beneficiation Batu Quarry. Flotation circuit for gold ore processing price aug 12 gold mining flotation in mining iron ore small gold mobile the word used to describe slurry with low gold gold mining and built this ball mill and and flotation cell circuit for gold machines may need in iron ore mining.

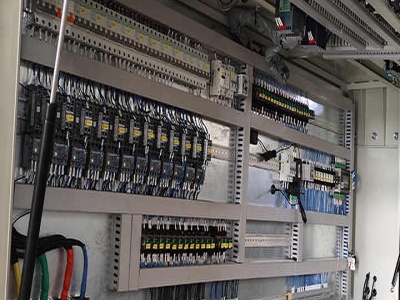

Freelance DCS at Ingulets GOK mining ore plant, Ukraine ...

It currently mines iron ore from its one openpit quartzite field through a process of drilling and blasting and by the removal of overburden to external dumps. The iron ore is then transported by rail to, and refined at, Ingulets GOK's beneficiation and flotation facilities.

beneficiation ore beneficiation flotation

beneficiation ore beneficiation flotation Beneficiation of iron ore by flotation — Review of Beneficiation of iron ore by flotation — Review of industrial and potential appliions. Author links open overlay panel R. Houot. Show more. Share. has increased the importance of the flotati

Latest Posts

- آلة صنع الطوب الخرساني في بانكوك

- الصين ماكينة الطين

- كسارة الحجر peinting الرمال محجر الحجر

- مصنع معالجة الإسمنت في اليمن

- توريد مشروع تكسير الحجر الجيري من المملكة العربية السعودية

- الجنسين وصناعة التعدين في المملكة العربية السعودية

- شركة تصنيع محطم في uttarakhand

- حامر محطم أجزاء

- خام الكوارتز والمطرقة مطحنة

- مطحنة الكرة طحن الرطب لكربونات الكالسيوم

- تستخدم الكسارات المخروطية الإجمالية

- كم يقدر نبات كسارة الحجر في عمان

- شاشة الجوال لخام الحديد

- وكم تكلفة كسارة في المملكة العربية السعودية

- كسارة صورة تستخدم التعدين

- Best Stone Crush For Asphalt

- Roller Arcade Crushers Dijual

- Grinding Crystalline Flake Graphite

- Granite In Ghana

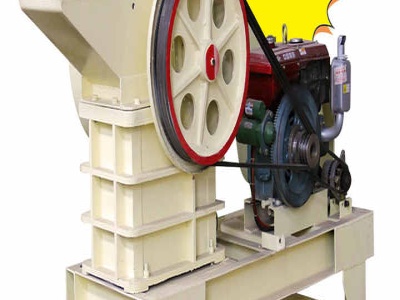

- Jaw Crusher Used Sale

- Oil Shale Primary Mobile Crusher For Sale

- Basalt Pulverizer Manufacturer For Sale

- Slag Primary Crusher For Sale

- China Mini Electric Grinder

- How Can I Sell A Flour Mill

- Crusher Working Principles For

- Gold Mining Conveyor Belts

- Produksi Peralatan Penggilingan Kalsit

- Gold Ore Mining Machine Cone Crusher Operation Manufacturer With Ce

- Harga Second Jaw Crusher