Grinding Technology Mineral

Fives | Crushing and grinding technologies

Our grinding technologies also include 3rd generation classifiers, flash drying systems, and process filters that enhance plant performance, for both new plants and modernization projects. Minerals crushing. Fives develops equipment and integrated plants for dry process mineral grinding appliions.

Energy Use of Fine Grinding in Mineral Processing

· as polishing the mineral surface, which can enhance recovery. DOI: /s The Minerals, Metals Materials Society and ASM International 2013 I. INTRODUCTION FINE grinding is becoming an increasingly common unit operation in mineral processing. While fine grinding can liberate ores that would otherwise be considered

GTS Grinding Technologies and Systems

Read details grinding test. provides at its headquarters a testing equipment for industrial grinding to test the process capacity and study the most suitable solutions. Moreover, offers easytoinstall pilot equipment at the customer's production site in order to test the machine capacity in actual working conditions.. Read details focus on A new model of the MG Series

Global Mineral Grinding Market 2021: Key Strategies ...

· Global Mineral Grinding Market Growth (Status and Outlook) from is a significant source of keen information for business specialists. The report is an overall investigation and thorough information in regards to the market size and market elements.

Lab Grinder_GTEK MINERAL TECHNOLOGIES CO.,LIMITED.

Cixi City, Zhejiang Province, China. +86159 5822 9409 +86138 6784 5744; gtek

Mineworx Files Patent on New Mineral Grinding Technology

· Iberian Minerals Ltd. announced today that its 100% wholly owned subsidiary, Mineworx has filed for patents on its proprietary HM XMill grinding technologies.

Survey

It is often said that mineral processing as an industry is slow to react to new and innovative technologies, but detailed reports on the perception and adoption of innovation in mineral processing seem to be few and far between. At Grinding Solutions Ltd. we are interested in your opinion on the who, what, where and...

Laboratory Grinding Method

Lab rod mills tend to produce a particle and mineral P80 of similar size (can vary when high levels of mica or similar), but the plant closed circuit mill with a hydroclone can give finer grind size of the heavier minerals. This ultimately might mean that that the plant grind size can be coarser than the lab grind .

Mining Minerals Processing

Crushing Grinding Wet – Magnetic Separation Dry Magnetic Separation Fine Flotation Leaching Classifiion Coarse Flotation LIMS DWD RED RED 2 Eriez is the world authority in separation technology used throughout mineral processing operations. The magnetics division features low, medium and high

Intelligent Grinding Technologies for the 21st Century ...

· Ultrafine Grinding: The latest technologies in ultrafine grinding, without using stones, of course, to produce Turkishtype grinds. Bimodal, or Plurimodal, Grinding: This most recent technology allows for the grinding of two grinds, each with an ideal average particle size, thereby optimizing the specific and individual ele ments of coffee extraction related to both fine and coarse grinds.

Ore Processing Challenges in Gold Operation Grinding Circuits

· Particle size monitors use ultrasonic attenuation technology to provide particle size analysis of a mineral slurry stream. They can help ensure the final grind target at each instant of the process. Continuous, realtime feedback will instantly alert the plant manager to process upsets, allowing a quick reaction to lessen the impact.

Mineral Grinding Market 2021 : Global Industry Analysis ...

· Sep 15, 2021 (The Expresswire) Global "Mineral Grinding Market" to grow with a impressive CAGR over the forecast period from . The report on...

Grinding | ABB

To ensure profitable operations, an efficient grinding circuit has to be designed, especially now, where global mineral resources are decreasing and the exploitation of lowgrade deposits become necessary. More powerful and larger mills, higher ball charges and demanding ambient conditions call for a strong partner for grinding solutions.

IsaMill Technology Used in Effecient Grinding Circuits

A real need had arisen for a technology that could grind to ultrafine sizes in metallurgical operations economically and without serious contamination of mineral surfaces and pulp chemistry. However in 1990, there was no generally accepted technology for regrinding economically to .

The nextgeneration high pressure grinding roll

Based on over 40 years of experience in the minerals industry and more than 150 HPGRs installed worldwide, thyssenkrupp has further developed the technology. The HPGR Pro offers up to 20 % more throughput, up to 15 % lower energy consumption, and up to 30 % longerlasting rollers.

Reinforcement Learning for Grinding Circuit Control in ...

Grinding, reducing the particle size of mined ore, is often the bottleneck of the mining concentrating process. Thus, even small improvements may lead to large increases in profit. The goal of the grinding circuit is twosided; to maximize the throughput of ore, and minimize the resulting particle size of the ground ore within some acceptable range. In this work we study the control of a ...

Ultrafine powder grinding classifying technology ...

Calcium carbonate ultrafine powder grinding and classifying technology. ... Therefore, it is not only an ideal choice for grinding high hardness, abrasive mineral raw materials, but also the most economical choice for grinding white filler minerals such as low hardness calcium carbonate.

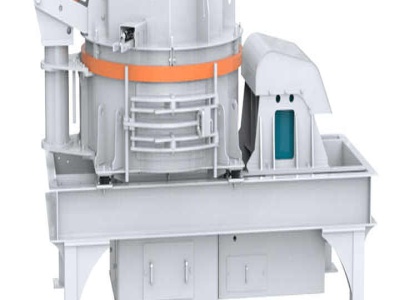

Mineral Grinding Technology | Claudius Peters

Mineral Grinding Technology Claudius Peters is widely acknowledged as one of the foremost authorities on coal and mineral grinding technology. With knowledge gained in over 700 appliions of our famous "EM" ball ring mill, we offer reliable solutions for the most extreme processing challenges.

grinding in mineral processing

Wills' Mineral Processing Technology – – Elsevier. This new edition has been prepared by the prestigious J K Minerals Research Centre of ... Energy Use of Fine grinding in mineral processing Springer . Grinding can be classified into coarse, .

Particle Analysis in Mining and Minerals

Many of the particles encountered in mining are characterized by sieves (classifiers). Recent advances in computers, cameras, and software make image analysis practical for samples with sizes larger than several microns in diameter. As particle size decreases, sieving and/or dynamic image analysis becomes more arduous or impossible and laser diffraction becomes the technique of choice.

Russell Mineral Equipment · Welcome · Fast, Reliable, Safe ...

RME is the global leader in the design, manufacture and supply of grinding mill relining technologies and services. Mill relining is the most specialised and important task in the maintenance of a mineral concentrator. Mill relining dictates shut down times, mill availability and utilisation, throughput, and therefore mine site profitability.

AuraSource, Inc.

Ultrafine Grinding and Separation Technology. AuraSource is a technologydriven company focused on developing and implementing clean energy and mineral processing technologies. We are commencing operations with two hydrocarbon clean fuel technologies: AuraCoal™ and AuraFuel™, and a mineral processing technology: AuraMetal™, all of which ...

DARAGRIND® Mineral Grinding Aid | GCP Applied Technologies

· Daragrind™ is one of the largest product developments by GCP Applied Technologies in the field of Grinding Additives for minerals, cement raw materials, coal, pure calcium carbonate, limestone, silica and quicklime.

Latest Posts

- أفضل محطم وناقل للفحم

- آلة صنع الذهب للبيع مصر

- واحد كسارات تبديل الفك مصر

- 5 1 2 كسارة مخروطية

- كسارة في دلة دلة للركام

- مطحنة الكرة الكوارتز الصغيرة

- داخل مطحنة المطرقة

- خطة أعمال تعدين الجرانيت الحجري

- صخرة محطم للبيع جديدة

- الفضة ختم مطحنة تصميم

- مصنع استخلاص رمل السيليكا للزجاج

- كسارة الحجر نوع السعر 400

- معدات التعدين مطحنة

- آلة صنع الطوب الجيري

- مضخة الطرد المركزي المستخدمة في أنظمة الغسيل

- Manual Book Of Cone Crusher

- Manganese Ore Vsi Crusher Manufacturer

- Spare Parts Of Baioni Crushing Plants

- Nugget Metal Detector Schematics

- Mesin Crusher Batubara Indonesia

- Use Truck Mount Rock Crusher For Sale Usa

- Mobile Crushers Uk Hire Liverpool

- Gold Mining Por Le Equipment Manufacturwers

- Jaw Crusher For Crushing Coal

- Ball Mill Gear Reducer

- Stone Crushing Plant Thailand

- Hoper Feeder Crhuser Plant Desig Youtube

- Masala Machin Manufacture In Nagpur

- Mill Mineral Stone Grinding Mill

- Hiring Mining Equipment Cost Nigeria In Zimbabwe