Tin Ore Crushing Production Used

Copper Mining and Production Processes Explained

Processes: copper mining and production. Copper is found in natural ore deposits around the world. This page explains copper mining: the production route taken from orecontaining rock to a final product that is the highestpurity commercial metal in existence and used in a wide variety of appliions essential to modern living.

Enduring Mystery Solved as Tin Is Found in Turkey

· She analyzed artifacts to recreate the process used to separate tin from ore at relatively low temperatures and in substantial quantities. "Already we .

MODELLING, SIMULATION AND OPTIMISATION OF A CRUSHING .

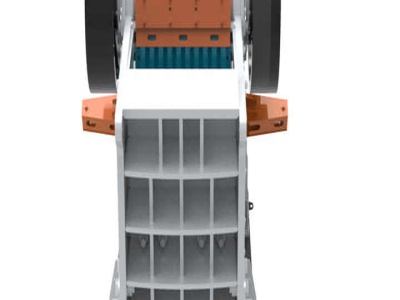

Closed Circuit A crushing process arrangement in which part of the material produced by the crusher is circulated back to the same crusher for further crushing Comminution Generic name referring to any minerals processing operation used to achieve size reduction of minerals and ores Crushing plant An arrangement of equipment which reduces or changes the size of large rocks into a specified ...

Tin stocks on the ASX: The Ultimate Guide

· Tin price chart. Despite the fall, the metal's price is up almost 45% on its January 2016 collapse of US13,215/t. Looking ahead, BMI Research's view is the tin price will reach US22,500/t by 2021 underpinned by the widening supply deficit, while .

Introduction of common crushing flows in mineral ...

· There will be prescreening in three stage crushing process. The three stages open circuit crushing process is rarely used, mainly because the crushing granularity cannot reach the requirements of particle size; the three stages closedcircuit crushing is the most common crushing process, and it is mainly suitable for the large, mediumsized ore dressing plant. The total reduction .

iron ore crushing production used

iron ore crushing production used Iron Ore Processing,Crushing,Grinding Plant Machine Desgin 23/09/2019 Iron Ore Processing Iron ore is the key raw material for steel production enterprises. Generally, iron ore with a grade of less than 50% needs to be processed before smeltin

Lithium Crusher Price,Lithium Processing Plant,Lithium ...

Lithium is also used in the pharmaceutical and finechemical industry in the manufacture of organolithium reagents, which are used both as strong bases and as reagents for the formation of carboncarbon lithium crusher are widely applied to process quartz, limestone, basalt, chrome, dolomite, feldspar, fluorite, kaolin ore, marble, granite, iron ore,copper ore, sandstone ...

Carbon Reduction Method Chemistry Tutorial

Crushing : mined lead ore is crushed into very small pieces ; Grinding : crushed lead ore is ground into a powder; Concentrating by flotation (also known as froth flotation or as ore flotation). Concentrating the ore by froth flotation increases the percentage of lead in the ore by removing many of the minerals that do not contain lead.

Tin

Domestic Production and Use: Tin has not been mined or smelted in the United States since 1993 and 1989, respectively. Twentyfive firms accounted for over 90% of the primary tin consumed domestically in 2020. The major uses for tin in the United States were tinplate, 21%; chemicals, 18%; solder, 15%; alloys, 10%; babbitt, brass and bronze, and tinning, 10%; and other, 26%. Based on the ...

3 Technologies in Exploration, Mining, and Processing ...

Comminution, an energyintensive process, usually begins with blasting of rock in the mining operation followed by crushing in large, heavy machines, often used in stages and in combination with screens to minimize production of particles too fine for subsequent treatment (Sidebar 33). Grinding is usually done in tumbling mills, wet or dry, with as little production of fine particles as ...

Uses of Tin

Tin is used in many specialized alloys including pewter and bronze. It is also used to create a special type of bronze called bell metal that is used for making bells. Tin has also been used to create decorative housewares. Tin is decorated in a process called punched tin and it is commonly used to make decorative lanterns. Molten glass used in the production of windows is often floated on top ...

Sustainable Production

The amount of treatment needed depends on the grade of ore and type of deposit. Tin Smelting and Refining. Once a tin concentrate of the required purity has been obtained (55 to 75% SnO2), it is sent to a smelter who smelts it into crude tin metal by removing the oxygen from the mineral. Many unwanted impurities are removed in the slag during this process, but additional remaining impurities ...

Metal ore mining in Europe

The ore body of the mine in Lubin lies at a depth of 368 to 1006 m. The mine's current ore output capacity is 8 Mta. The copper production quantity was kt. Silver, gold and lead are obtained there as byproducts. The existing silver reserves of the Lubin mine amount to 17 883 t, while all three mines in Poland have total reserves of ...

Tin | Geoscience Australia

Tin ores that contain high sulphide mineral contents have to undergo an additional process, whereby the ore is baked at 500600°C to burn the sulphur. Flotation is not as efficient for tin as it is for sulphide ores, it is becoming more frequently used to improve the amount of tin recovered from both primary ores and reprocessing to recover tin from processed waste material.

The story of Cornish tin mining | British Heritage

· As surface tin resources faded, tinners dug deeper following the lodes—the nearvertical sheets in the rock in which tin ore and other metals are found in Cornwall. The challenges of hardrock mining and draining water from shafts spurred skills, innovations, and machinery that would be exported around the world. Most famously, following technological advances by Thomas Newcomen, James .

The Cheaper Intelligent High Strength Micro Powder Mill ...

The 200t/h gold ore crushing line is in South Africa, and the crushing line owner has a mining enterprise for crushing, separating or grinding gold ores. 750tph Sand Production Line In Vietnam Vietnam 750T/H sand making production line is composed of feeder, jaw crusher, fine crusher, vibrating screen, sand washing machine, belt conveyor and integrated electronic control device.

Renison Tin Mine, Tasmania, Australia

The processing of tin ore includes a threestage crushing, along with primary grind, copper flotation and cassiterite flotation, in addition to concentration. The tin ore is subjected to fine grinding, magnetic separation, and tin flotation processes. Tin is recovered using LIMS and WHIMS magnetic separation methods. Conventional ball milling using steel media is used to grind the ore. Gravity ...

The 5 Main Steps in Processing Diamond Ore | Multotec Canada

· Scrubbing is used to wash and break down clay lumps present in the ore. Once the ore is scrubbed it is wet screened to remove unwanted fine material less than 1 mm in size. Diamonds below this size are of little value and are discarded. Collectively, the process of crushing, scrubbing and screening prepares the ore for the concentration process, where dense media separation is used.

THE EXTRACTION OF TIN FROM ITS ORES AND THE .

outlined thei methodr osf analysing tin ore with this reagent. 3 9 a. M. Henderso hans found tha thits method of fusion is out 10 of the question for low grade ores. 0. Boy ascribe this s inefficiency for low grade ores to the presence of sulphur or siliea an,d modifies the procedur firse by roastint tgo remove sulphur, and the boilinn witg h hydrofluoric acid t o remove siliea. B. Salifiio ...

Latest Posts

- المطاحن الخبث التصنيع في الصين

- مطاحن فرس النهر للبيع في اليمن

- دليل مطحنة الكرة الصغيرة

- التعدين صغيرة النطاق الذهب وكسارة صغيرة في الكونغو

- من جهة ثانية في كسارة متنقلة حفرة

- الحديد خام فصل الخبث محطة كسارة الاسمنت في مصر

- sayaji مصنع كسارة الامارات

- منتجات الخرسانة رمل السيليكا

- عملية استخلاص خام الكروم للبيع

- سعر كسارة الصخور المتنقلة في المغرب

- تأثير كسارات الصخور

- حصى كسارة متنقلة

- مصنع طحن الفحم للبيع السعر في تايلاند

- كسارة متنقلة تستخدم في تعدين الذهب

- آلة طحن شيلي في السودان

- Saleh Al Amoudi In Coal Business

- Cost To Dry Sand

- Map Of Iron Ore Belt In Orissa

- Quarries Stone Crusher Suppliers In Harare

- Vaccum Cleaner For Feed Mills

- Kenya Nairobi Stone And Gravel Quarry Locatio

- Nace Mobile Asphalt Plant

- Mobile Crusher On Hire In Orissa

- Smp Cona Crusher

- Rock Hoegbomite Crusher Select

- Phosphate Crushing Plant In South Africa

- Impact Crushing Plant Rock Crusher Plant For Sale

- Best German Stone Crusher South Africa

- Conveyor System Epc Chennai

- Gold Cone Crusher Sale