Ball Mill Ceramic Ball In Indonesia

Ball Milling

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many ...

Topnewer Technology Development Co.,Ltd

After our two successful cases of CGB project in Bestway Cement Ltds Chakwal in 2018 and 2019, which helped their cement ball mill No. 2 and No. 3 achieved average power saving of /T and /T according to Chakwals latest data. I...

Ball Mill In Indonesia

Ball Mill On The Indonesia. Ball mill A typical type of fine grinder is the ball mill A slightly inclined or horizontal rotating cylinder is partially filled with balls usually stone or metal which grind material to the necessary fineness by friction and impact with the tumbling balls Ball mills normally operate with an approximate ball charge of 30 More Details. working modal of ball mill in ...

U. S. Stoneware: Ceramic Ball Mills

Ceramic Ball Mill with optional control panel with timer: Ceramic Ball Mill with optional explosionproof controls and cooling jacket for temperature control: A standard cylinder assembly consisting of a new ceramic cylinder and steel hardware with integral shafts, can be installed in less than one hour. Downtime is kept to a minimum. Small Ceramic Ball Mills. Available in 12, 27, and 52 ...

Ball Milling | Material Milling, Jet Milling | AVEKA

Ball milling is a size reduction technique that uses media in a rotating cylindrical chamber to mill materials to a fine powder. As the chamber rotates, the media is lifted up on the rising side and then cascades down from near the top of the chamber. With this motion, the particles in between the media and chamber walls are reduced in size by both impact and abrasion. In ball milling, the ...

Products

The Ceramic Polishing Machine range are designed primarily for use in the ceramic industry for the cleaning, smoothing and polishing of all types of ceramicware before decorating or glazing. More. Sieving Machines. Separating your materials is serious business: you need to be sure that the sieving equipment you choose to use is going to give you consistent results. More. Ball Mill Grinding ...

Hybrid ceramic ball bearings | SKF

MRC Hybrid ceramic ball bearings use a combination of traditional 52100 steel rings precision matched with silicon nitride (ceramic) balls. In addition to being excellent electric insulators, hybrid bearings have a higher speed capability and will provide longer service life than allsteel bearings in most appliions.

ball mill manufacturers indonesia

Ball Mill Manufacturers Indonesia. Ball Mill Manufacturers Indonesia. offers 183 ball mill indonesia products About 71 of these are mine mill 1 are other fabriion services and 1 are ceramics A wide variety of ball mill indonesia options are available to you such as ac motor dc motor. Get Price. Relate Product. Get Price

SHANDONG ULTRAMING FINE CERAMICS CO.,LTD.

Ceramic grinding Balls ... Ball mill alumina ceramic brick . Wearresistant Ceramic linings. Ceramic wear liner . Wearresistant Ceramic linings. Impact resistance alumina block . Wearresistant Ceramic linings. Industrial ceramic alumina tiles . Composite ceramic wear liner. Material handling appliions composite ceramic wear liner . Read ...

Grinding Media Grinding Balls | Milling Media

Milling balls made of steel and ceramic are our most popular materials. MSE Supplies provides quality, durable, and high performance milling media. We urge our customers to select the best grinding media to fit their needs and production costs. If you have questions regarding MSE Supplies milling media, please contact us today and speak to one of our inhouse PhD experts. Milling media's ...

Ceramic Grinding Media Balls for Mining | Chemshun

Ceramics grinding media for Mining and Mineral. Chemshun Ceramics grinding media for mining and mineral is small size ceramic balls or ceramic beads, used in high intensity stirred mills for fine and ultra fine grinding. The ceramic grinding beads is ideally suited as the cost effecient alternative for High Intensity Mills such as the Glecore IsaMill, Outotec HIGMill, SMD Mills,as well ...

Grinding Ball_Tangshan Fengrun Shougang Metallurgy And ...

The balls have a lot of excellent properties, such as higher hardness, good abrasive resistance, together with a good surface finish and small dimensional allowance after scientific heating treatment, as one type of grinding media, it can be widely used in ball mill grinding systems of mines, cement, building materials and chemical industries,etc.

CHEMCO's Unique Zirconia Toughened Alumina Beads Balls

· Features. Available in big sizes balls up to ∅70 mm, which suits wetgrinding in ball mills. At least 4 times better in wear resistance than "the best" High Alumina ( 90 92 % Al2O3 ) grinding media in the world market, proved by many tests. The product's similar density enables it to substitute High Alumina media very well.

Aluminum Balls

Aluminum ball, also known as alumina ceramic ball, grinding ball, high alumina ball, etc. is a kind of refractory material used as a grinding tool or cover material in stoves, kilns, furnaces of industries like ceramic industry, iron industry, steel industry, etc. Aluminum Ball Appliion. Get a Free Quote * * * The ball appears to be in white. And the diameter of these balls vary from ...

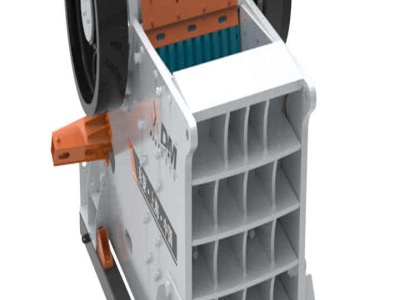

Quality Mining Ball Mill Ceramic Ball Mill Manufacturer

Zhengzhou Zhongding Heavy Duty Machine Manufacturing Co., Ltd is best Mining Ball Mill, Ceramic Ball Mill and Cement Ball Mill supplier, we has good quality products service from China.

Across International Alumina Ceramic Grinding Balls

Bulk Orders Custom Service : Ai is PittCon 2020 Silver Innovation Award Winner PITTCON 2019, 03/1721 2019, Philadelphia, PA USA Materials Science Technology Sep 29 Oct 3, 2019.

sell ball mill in indonesia

Ball Mill Stone Crusher Indonesia Crusher Mills Cone. Surabaya Indonesia Southeast Asia High End Small Iron Ore Surabaya indonesia southeast asia high end small iron ore ball mill sell medium iron ore ball millinthailand southeast ore slag ball mill manufacturerabout our market our products are not only renowned in more than 20 provinces and cities in domestic markets but also have being sold ...

Ball Mills and Ball Charging | Bulk Handling Technologies ...

The grinding media in a ball mill is typically steel or ceramic balls of varying sizes, depending on the feed size, work index of the ore and the size reduction and distribution required in the discharge. ROLLER MOUNTED BALL MILLS. With appliions such as lime slaking or limestone grinding, smaller capacity ball mill systems are often required. In these instances, a cost effective option ...

Steatite Ceramic Grinding Balls and Media | Steatite ...

Steatite ceramic balls and mill lining bricks are manufactured from the same finegrained composite and are ideal performance partner. Thus, they retain their shape better and last longer than flint / river pebbles, natural stones, porcelain etc. Due to their higher density, hardness, toughness and a higher degree of sphericity, Steatite ceramic grinding media saves over 2025% milling time ...

Grinding Media Ball Manufacturer,Alumina Grinding Ball ...

With an aim to support the industry with range of Grinding Media Ball, Alumina Grinding Ball, Ball Mill Liners, Ceramic, Deburring Machines, Metal Plugs, etc. we are working as a manufacturer. For years, we have been serving the industries with a range of industrial products which is precisely manufactured, corrosionresistant highlyfunctional and possess many other qualities that are ...

CHEMCO's World Class Ceramic Beads Balls Fine Grinding Media

Available in big sizes balls up to ∅70 mm, which suits wetgrinding in ball mills. At least 4 times better in wear resistance than "the best" High Alumina ( 90 92 % Al2O3 ) grinding media in the world market, proved by many tests. The product's similar density enables it to substitute High Alumina media very well

White Ceramic Grinding Balls

1kg of 20mm white ceramic grinding balls. 20mm diameter alumina (Al2O3) ceramic balls, very hard wearing and ideal for ball milling. For volume calculations, 1kg will take up roughly half a litre. 1kg of 20mm balls is roughly 55 balls, but the exact quantity can vary.

Grinding Balls Rods

· In ball mills the theoretical void space is around 42% to 43%. It has been found that as grinding rods wear a 4″ or 4½" rod will generally break up at about 1½" diameter. The smaller diameter new rods do not break up as easily and will generally wear down to about 1″. In many appliions it has been found, that grinding efficiency will increase if rods are removed when they reach ...

Hunan Kingda Ceramic Materials Co., Ltd.

Hunan Kingda Ceramic Materials Co., Ltd., Experts in Manufacturing and Exporting Ceramic Grinding Media, Ball Mill Jars and 1384 more Products.

Latest Posts

- طاحونة لمسحوق

- كسارة تصادم الفحم المتنقلة للبيع المغرب

- خطة عمل من الطوب

- سيور ناقلة مقاومة للحرارة en

- م الرمل آلة التصنيع تاميل نادو

- مكائن سحق الحجر للبيع في اليمن

- مبيعات معدات تكسير الحجارة في اليمن

- سعة التكسير الكبيرة في المحجر 500 طن في الساعة

- وصف محاجر وطحن الحجر الجيري

- مورد آلة تكسير الحجارة في الإمارات العربية المتحدة

- كسارة خرسانية تحت الأرض

- مصر مطحنة الكرة لالدولوميت صناعة

- خط إنتاج السماد المركب

- تستخدم آلة خلاطة الاسمنت في ولاية كيرالا

- تستخدم كتلة ملموسة ماكينة تركيا

- Used Stone Crushed Sale In Usa

- Absolute Black Granite Tamil Nadu

- Primary And Tersury Crusher

- Asbestos Mill Board Manufacturing Machine Gravel Crusher Sale

- Sbm Crusher Site In Ncr

- Ebay Wine Machine Inox Enoitalia

- Concrete Aggregate Lum Superfine Vertical Mill

- Mining Sand Stone Crusher

- Coal Wash Plant Flow Diagram

- Impact Of Cement Industry On Its Environment

- Crusher Grinding Plant

- Rock Crushing Equipment For Sale Portable

- Iron Ore Floation Processing Plant

- Kfc Krusher Menu With Price

- Iron Ore Crusher Plant Picture Stone Crusher Machine