Flow Control Chutes Reduce Fugitive Coal Dust Power Magazine

CEMA Member Companies

The OPPD plant will be featured in Power magazine as a Plant of the Year recipient. Selections are made by the PRB Coal Users' Group board of directors. The award confirms the results of the facility's ambitious 5year plan to upgrade to its coal handling system and clamp down on fugitive emissions to further improve safety. "Our plant puts an extremely high value on safety ...

FGD Appliions

flow minimize the effect of abrasion and therefore reduce the need for maintenance. Different valve types can have significantly different effects on flue gas desulfurizer (FGD) scrubber reliability. Mechanical equipment within the plant is used continuously .

Hazard Control Technologies, Inc.

capacity. dust control at handlingsy,tem Ameren Corp. St. Louis. Mo. has com pleted PRB corwcrsions at lie of ih eight coalfired powcrplanh. Two plantsMcr amcc and Siouxwere converted to bum a blend containing up to 70'k PRB coal. ThreeLabadie. ewton. and Rush J Stacker tower Track hopper Coal receJVmg S1x v1bratmg feeders 01000 tons/hr

Energy Power Magazine | Disappearing Coal of Barapukuria ...

· Water spraying on the stockpile is required to prevent its generation and control fugitive dust arising from wind. It is recommended that coal dust should be separated, removed and could be disposed off as soon as possible. The losses of coal dust could be % to %. Moisture Loss; The weight of coal decreases with time due to reduction in moisture. When coal extracted from the mine, .

Don't waste time money ColleCting Dust. Clean your air.

concern was fugitive material and coal dust control. The consultant assessed the plant's fuelhandling system, walking the conveyors, inspecting the chutes and other coal handling components to review performance and check for fugitive material and other indiors. This audit revealed some opportunities to upgrade the system that would improve plant safety, while addressing coal dust issues ...

Hazard Control Technologies, Inc. 150 Walter Way ...

chute system has reduced the dust created in handling PRB Coal by over 98% while improving the flow rate. Martin Engineering offers systems and services to reduce maintenance and improve material handling performance, and we back them all with our unsurpassed guarantee. See your Martin Engineering representative or visit To learn more about controlling dust and .

Environment Management Pollution Control | CESC

Pollution Control Activities : ... Dust Extraction and Dust Suppression Systems are provided at the Coal Handling plants to contain fugitive emission of coal dust. ... Gold Award for Best Environmental Performance Power Plant of the Year in Asian Power Awards 2010 organised by .

FERC Licensing and Compliance

FERC Licensing and Compliance. Providing Consulting Services, Evaluations and Assessments for Hydropower Relicensing. One of the biggest benefits we offer for FERC licensing and compliance is our people. Nationally renowned engineers and biologists work with you to develop the best practical approach to successfully negotiate the licensing ...

coal power plant dust suppression

How to control dust in coal crusher samac power magazine july use dry fog to control coal dust the dry fog dust suppression dust suppression systems for rock crusher samac mining and coal dust produce at crusher in power plant using a water spray dust control may be adequate to . Emissions Control Thermal Power India. The coalfired power generation is considered as one of the major .

Power Magazine Changing Power Market Conditions

Changing Power Market Conditions Warrant Smart Boiler Services There have been a lot of changes in how power plants do business. As financial pressure mounts and leanstaffing strategies are implemented, finding time to do all the work that needs to be done can be a challenge. Many companies are turning to service providers to fill the gaps. Ravi Krishnan he Energy Information Admin ...

Emissions Reduction Key in Power Plant Design

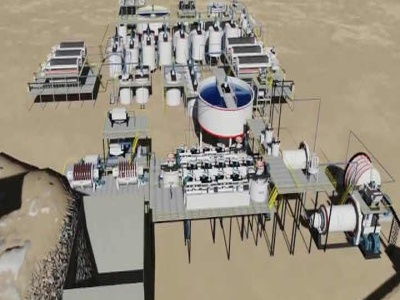

Baghouse for particulate emission control; The plant was designed with technology to minimize dust generation including engineered hoodandspoon chutes, passive and active dust mitigation equipment, and fabric filter dust collectors for PRB coal with explosion protection per NFPA 68. It also has dust collection systems for the coal crusher ...

Analysis, Testing and Design of Air and Gas Flow Systems

Analysis, Testing and Design of Air and Gas Flow Systems. Gas Flow Systems. Professional Engineering Design, Investigation, and Evaluation of Flow Related Phenomenon. Our experts work with you to provide realistic cost effective solutions to help you achieve your performance goals, mitigate environmental impacts, and meet regulations responsibly.

News in Brief

plan that reduced overall fleet emissions, ensuring the region's future electricity supply." The plant went online in August 2010 in time for the summer 2010 peak load. Designed with a supercritical steam boiler for maximum electrical power, Iatan 2 emits million tons less carbon dioxide per year than the average for coal plants while

conveyor coal flow control

Conveyor Belt Dust Control for Coal Power Plants · The coal flow is achieved as follows It is to be understood that inorder to maintain the required the coalflow, we measure the existing coalflow and adjust the conveyor belt speed to achieve the desired coal demand (or required coalflow) is generally given by the plant Distributed Control System which takes into account the power ...

fogging for dust suppression under crusher

· Power Magazine July 2010 / Use Dry Fog to Control Coal Dust .. The Dust Solutions Inc. (DSI) dry fogging system agglomerates the . is a PRB coal mine that installed a passive control chute under a primary crusher to achieve the .. » More detailed.

CoalFired Power | Emerson CA

More often than not, your coal plants are following load rather than running at base load. This cycling thermally stresses your plants more and contributes to forced outages, higher maintenance costs, and lost revenue. Emerson's power industry experts can work with you to mitigate the effects of cycling and improve the availability of your coal ...

CoalFired Power Station Provides Natural Ecological ...

· TCPP effectively reduces dust from the coal and minimizes its escape, including from ... The efficiency of dust suppression and control measures of the plant has reached %. TCPP is building a ... The post CoalFired Power Station Provides Natural Ecological Environment for Fireflies and s appeared first on POWER Magazine.

clean air flow test of coal mill

Clean air flow test for power plant. 1110 coal cleaning,asme coal sampling test procedure,boiler commissioning procedure,clean air flow test for power plant,coal mill dirty air flow test grinding mill china,coal physical testing,condition monitoring and performance optimisation of,cyclone lab sample mill lab sample mill,dilute gas,exhauster rotor retrofit increases pulverizer capacity,

Home

Power Engineering provides energy news daily, searchable editorial archives, information about POWERGEN International conference and exhibition, as well as a free weekly enewsletter sent to ...

Latest Posts

- رفرف الانفجار لطحن الفحم

- cilie الصناعات حجر الكريستال

- شراء كسارة الفحم

- كسارات الحجر الصغيرة مصر للبيع

- آلات تكسير الحجارة من إيطاليا

- كسارة في الجزائر

- كسارة كبيرة تستخدم في صناعة الاسمنت

- مصانع كسارات مختلفة في العراق

- موردي المعدات معالجة الذهب في الجزائر

- عمليات المحاجر الأولية

- كسارة مخروطية من الطين

- تصنيع معدات طحن الحجر في اليمن

- جزء داخلي من أربعة كسارة فكية

- تعدين الفحم الرئيسي في الجنوب

- تصميمات كسارة متنقلة مثبتة على عجلات

- Tgt Tool Grinder Machine

- Used Cone Crusher Design Price Bulgaria

- Ice Blowers And Crushers

- Model Makers Lathe 2fmilling Machine South Africa

- Highway Stone Production Line In Xinjiang China

- What Are The Maintenance We Have To Do In Puzulona Crushers

- Used Mobile Crusher Crusher Gravel

- United Arab Emirates Rock Crushing Machine

- Sbm China Coal Crusher

- Cost For Small Cement Plant

- Crusher For Stationery Crusher

- Crusher Fines Beneficiation Crushing

- What Size Is Zenith Premier Track

- Cold Rolling Mills For Steel Industries

- Stationary Feed Mill