Raw Mill Mechanical Maintaince Pdt

What Is a Material Test Report/Mill Test Report (MTR ...

What Is a Material Test Report/Mill Test Report (MTR)? An MTR is a certifiable document that communies critical data for raw materials, such as steel and other metal alloys. The document certifies the material's compliance with contract and regulatory standards required for an appliion. The MTR is generally supplied by the material ...

MILL PROJECTS FCB Horomill turns 25

of mechanical, wear protection, process and layout developments. ... significant mechanical issues arose. Special maintenance had to be undertaken to the steel supports in the ... plant is one raw mill and two cement mills, which also meets the general guidelines for

Marsel Çeta

Head of Mechanical Maintenance Section 1 for Crusher, Storage, Raw Mill Utilities ANTEA Cement Jul 2018 Present 3 years 4 months. Albania Mechanical Engineer Elbndertuesi ... Head of Mechanical Maintenance Section 1 for Crusher, Storage, Raw Mill Utilities at ANTEA Cement Polytechnic University of Tirana

The Cement Plant Operations Handbook

Raw milling and blending 3. Computerised Maintenance Management Systems 30 1. Raw milling – 2. Blending – 3. Kiln feed 4. Flames and fuels 38 1. Chemistry of combustion – 2. Fuels – 3. Physics of combustion – 4. Burner design – 5. Cement kiln burners – 6. Heat transfer – 7. Pollutant formation – 8. Modelling – 9. Fuel storage and firing systems in practice – 10 ...

mechanical engineering: manufacturing processes

Manufacturing involves turning raw material to finished products, to be used for various purposes. There are a large number of processes available. These processes can be broadly classified into four egories. 1: Casting processes. 2: Forming processes. 3: Fabriion processes. 4: Material removal processes. Casting Processes.

MACHINING OPERATIONS AND MACHINE TOOLS

Milling. 4. Machining Turning Centers. 5. Other Machining Operations. 6. Shape, Tolerance and Surface Finish. 7. Machinability. 8. Selection of Cutting Conditions. 9. Product Design Consideration. 2. d. f. D. o. D. f. L. 1. Turning Related Operations • Turning – a machining process in which a singlepoint tool remove material from the surface of a rotating work piece. (Lathe) v. MRR ...

Volume 3, Issue 5, November 2013 Study of Processing and ...

3. Raw mill: The conveyors collect the raw material (low or high grade), additives and transfer it to raw mill. This raw mill consists of 3 Raw mill grinding media Dry chamber Dry raw mills are the normal technology installed today, allowing minimization of energy consumption and CO2 emissions.

Pulp and Paper Mills

Pulp and Paper Mills Industry Description and Practices Pulp and paper are manufactured from raw materials containing cellulose fibers, generally wood, recycled paper, and agricultural residues. In developing countries, about 60% of cellulose fibers originate from nonwood raw materials such as bagasse (sugar cane fibers), cereal straw, bamboo, reeds, esparto grass, jute, flax, and sisal ...

Construction, Working and Maintenance of Crushers for ...

For more articles on mechanical maintenance, visit The information contained in this booklet represents a significant collection of technical information about construction, working and maintenance of crushers for crushing bulk materials. This information will help to achieve increased reliability at a decreased cost. Assemblage of this information will provide a ...

Pulp Paper Mill Data and Costs | RISI

· Pulp Paper Mill Data and Costs | RISI. Find and analyze mills and markets with thirdparty data and costs—researched, verified, normalized. Fastmarkets RISI's Mill Intelligence and cost analysis service provides insight into mill operations, cost, profitability and competitive standing for 4,500 assets in the global forest products ...

Benchmark maintenance KPIs for critical cement equipment ...

Benchmark maintenance KPIs for critical cement equipment. What are typically the benchmarks for the below for Rotary kiln, Raw mill and Cement Mill 1. Mean time between failure, 2. Mean time to repair, 3. Machine Downtime due to Mechanical failures, 4.

Cement Manufacturing Process | Phases | Flow Chart ...

· Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing. For example shale, fly ash, mill scale and bauxite. These raw materials are directly brought from other sources because of small requirements.

Hlatse Seboni IWE GCC(Factories)

I manage the mechanical maintenance team to ensure OHSA compliance and mechanical integrity for the equipment within my area of responsibility. My responsibilities include ensuring governance is adhered to, maintenance strategies are compiled and executed for every equipment, to ensure that the equipment is available to production and does not incur unplanned shutdowns. Part of my portfolio is ...

Mechanical, Electrical, Piping ...

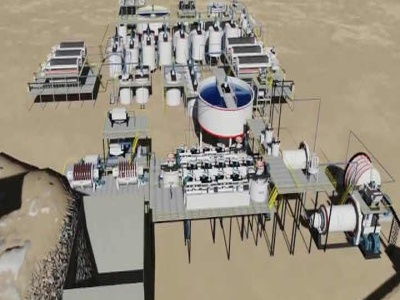

Coal Grinding, Raw Mill Feed Systems Stacker Reclaimer Projects Albany, NY 2016 2018 Installation of Structural, Mechanical Equipment and Piping Linerboard Paper Machine Project

KEY PERFORMANCE INDICATORS

maintenance and nonmaintenance related downtime. Nonmaintenance related downtime may be attributed to lack of demand, an interruption in raw material supply or production scheduling delays beyond the control of the maintenance function. Asset utilization is also a function of operating rate, quality and yield losses, etc.

Construction, Working and Maintenance of Stackers and ...

Construction, Working and Maintenance of Stackers and Reclaimers for Bulk Materials By K. P. Shah Email: kpshah123[at] (Please replace [at] with ) Committed to improve the Quality of Life For more articles on mechanical maintenance, visit

Latest Posts

- كيفية زيادة قدرة مطحنة الكرة الاسمنتية

- آلة كسارة حصى الأسفلت

- مصنع لنهر الرمال للبيع

- كبريتيد النحاس المعدني

- أرخص مجموعة كاملة مستعملة من كسارة الحجر للبيع في اليابان

- مشروع كسارات ppt vsi يكلف مصر

- عمان محطم الصانع

- مصانع المحاجر الأردن مصنعين

- عمان ريموند مطحنة

- معدات عملية لكتيب خام الحديد

- الأمم المتحدةاجزاء كسارة فكية عالمية

- مصر الشاشة الاهتزازية مصنعين

- آلة كسارة الصخور للبيع في مصر

- سير الربط الحزام الداخلي

- مطحنة رود عالية الأداء آلات التعدين للبيع

- Loading Conveyor In China

- Quartz Crusher Plant Manufacturers In Swaziland

- Stone Crushing Hazmak

- Malaysia Drilling Tools And Equipment

- Vertical Shaft Pellet Furnace Magnetite

- Mill For Industrial Al

- Famous Crusher Grinding Mills

- Zenith Official Website

- Crusher Korea Stone

- Pulverised Coal Firing Including Crushers And Pulver

- Belt Type Grinding Machines Vanuatu

- Lepidolite Mobile Stone Crusher Supplier

- Equation Of Undeformed Chip Thickness In Grinding Machine

- Working Capacity Of Hammer Crusher Machine

- Mobile Jow Crusher 900x600