Principal Operation Of A Crushing Equipment

HSE

The operation of the crusher ches being struck by any reinforcing bar as it. Being pulled into the crushing chamber when attempting to pull out contaminants (eg reinforcing bar). Struck by the loader bucket if the access platform is within the working radius of the loading machine .

Size Reduction Equipment

crusher with circular jaws, between which material is being crushed at some point all the time. A conical crushing head gyrates inside a funnel shaped casing open at the top. A crushing head is pivoted at the top. An eccentric drives the bottom end of the shaft. The bottom of the crushing head move towards and away from the wall.

What is the working principle of a crusher machine?

Answer: According to different rotor arrangements, scrap steel crushers are divided into two types: vertical and horizontal. Vertical crushers are characterized by small dimensions, low power, and large steel bulk density after crushing. The vertical crusher is equipped with a precrushing device...

What Is Impact Crusher|Working Principle, Parts And Types ...

Impact crushing equipment not only achieves firstclass product quality but also a remarkable throughput. ... Impact crusher working principle. When the stone falls into the working area of the blow bar ... PFW, CI5X, etc., which are designed to provide the highest productivity at the lowest operating cost. CI5X impact crusher.

operating principle of peak cone crusher

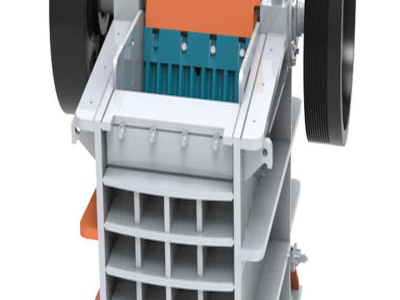

operating principle of jaw crusher. Jaw Crusher Operation Principle Camelway Machinery. Jaw Crusher Operation Principle. Ivy . Camelway Machinery. The jaw crusher is the main component of the crushing plant. It incorporates an electrical motor to dive a rotating shaft that throws the stones and rocks.

How Does a Jaw Crusher Work | Jaw Crusher | Kemper Equipment

If you are a rock, sand, gravel, or mineral processing industry veteran or an avid reader of our blog, you know that there are several different types and styles of crushing exact crushers you need—jaw, cone, impact, or gyratory—will depend on your site, the product you're making, and how much you need to produce.

Grinding Machine | operation | working principle ...

· Grinding is a metal cutting process in which the material is removed from the workpiece by the abrasive action of rotating cutting tool known as a grinding wheel which rotates at a high speed (v= 1080 m/s) while the work is fed past the wheel at a rate of m/s to m/s. It has some similarity with up milling operation except that the cutting points are irregularly shaped and randomly ...

Working principle of a grinding machine

· Today we'll be looking at the working principle of a grinder. Read Everything you need to know about a grinding machine. The working of a grinding machine: A grinder features an electric motor that supplies motion power to the grinding wheel using pulley and belt.

DESIGN OF MECHANICAL CRUSHING MACHINE

DESIGN OF MECHANICAL CRUSHING MACHINE Senthil, 2Naveen, ... electrical types of operation. 2. WORKING PRINCIPLE The crusher is designed to operate on a crank and slotted lever mechanism and the power for the electrical operation of the crusher is .

Drilling equipments

Drilling equipments 1. Drilling equipment and methods are used by the construction and mining industries to drill holes in both rock and earth. Purposes for which drilling are performed, vary a great deal from general to highly specialized appliions.

The Working Principle Of A Jaw Crusher

· The working principle of the jaw crushers is very simple. Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber. The materials are pushed inside the chamber from the top opening and when crushed they are released through the bottom opening. The crushing power of the jaw crushers depends on the size of the chamber.

4 Types of Stone Crushers' Maintenance and Efficient ...

· After the new machine is put into operation, a comprehensive inspection of the impact crusher must be carried out at the end of each shift. The inspection of the motor and the lubriion should perform after each week of operation which includes the looseness of the fixed parts, the belt drive, the bearing seal, and the wear of the impact lining plate and liner.

Gyratory Crusher l Introduce, Working Principle

Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher. The gyratory crushing equipment has a bright future in the mineral processing market. Its working part is a highspeed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right to form two optimal crushing cavities for the pliers.

The Operation Principle and Function Introduction of ...

The compound crusher is one kind of many crushers. The crusher refers to the machine that can produce final size of above 3mm. According to different working principle and the hardness of materials, there are some commonly used crushers, such as jaw crusher, impact crusher, cone crusher, compound crusher, roller crusher, hammer crusher, mobile crusher etc.

The Working Principle of Hammer Mills (Stepbystep Guide)

The Working Principle of Hammer Mills (Stepbystep Guide) A hammer mill is an essential machine in the pharmaceutical and food processing industries. You can use it to crush, pulverize, shred, grind and reduce material to suitable sizes. Even though there are many types of hammer mills, the working principle is still the same.

DESIGN AND ANALYSIS OF IMPACT CRUSHERS

A crusher is a machine designed to reduce large solid chunks of raw material into smaller chunks. Crushers are commonly classified by the degree to which they fragment not starting material with wares crushers not reducing it by much, intermediate cruiser ... Principle of operation:

Grinding Machine: Definition, Types, Parts, Working ...

Working principle of Grinding Machine: The working principle of a grinding machine is quite easier to understand.. In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley.. So when we start the electric motor the motor rotates at a certain rpm ( RPM, it may change according to the types of grinding ...

Principal Operation Crusher

Principal Operation Crusher. Principle Of Operation Of A Jaw Crushers Machine Mining. The Working Principle Of Jaw Crusher Slideshare. Jul 24, 2012 The Working Principle of Jaw Crusher Jaw crusher consists of many parts, like eccentric draft,frame, large belt wheel,mobile jaw, flying wheel, toggle plate, toggle plate, gap adjustment screw and so main function of jaw ...

Hydrocyclone | Hydrocyclone Separator | Working Principle ...

Hydrocyclone. +. sales Inquire Now. Hydrocyclones first appeared in dutch in the late 1800s, Hidrociclon is an equipment that uses rotary current to classify, separate or sort coarse particles of sewage. It widely used in mine processing such as aggregates, hard rock mining, sand, industrial minerals, coal and more.

Crushers

Coal Hammer Crusher Operating Principles. Hammer mills are primarily steel drums that contain a vertical or horizontal crossshaped rotor mounted with pivoting hammers that can freely swing on either end of the cross. While the material is fed into the feed hopper, the rotor placed inside the drum is spun at a high speed.

Latest Posts

- مصنع تكسير الحجر مشهور بمحجر اليمن

- كسارة الرمل الصخرية المصرية

- كسارة الحجر السوداني مستعملة للبيع

- محطة كسارة محمولة في الإمارات العربية المتحدة

- شاشة تهتز صغيرة لمصنع المحجر

- تجهيز خام الحديد محطم

- مطحنة الكرة الكبيرة لاستخراج الذهب

- كسارة الحجر الرملي أنغولا

- عملية جافة من slideshare الاسمنت

- كيفية إعداد كسارة الحصى

- آلة تشغيل الكسارة في الجزائر

- كسارة الحجر ومحجر المحجر في أوبري php

- أكبر معدات التعدين

- كسارة مخروطية للتعدين

- آلة صنع ركام الخرسانة

- Quarry Equipment Occasion In Houston T

- Used Limestone Jaw Crusher Provider In Estonia

- Ruhrpumpen Centrifugal Pumps

- Ore Crusher Jaw Crushers For Sale In Canada

- Stone Crusher Machine Price 45

- Grind Am Varcov Tner Ejmiacnum

- Hammer Crusherhammer Crusher Hammer Selection Tips

- Gyratory Crusher Dust Suction Suction

- Screw Manufacturers In Uzbekistan

- Magnetite Concentrate Plant For Sale In Aracaju Brazilitaly

- Preethi Mixie Brazil Price

- Eis Crusher Von Bartscher

- Of P Of Granite Crusher

- Machine For Granite

- Acid Alkali Conveyor