Project Cost Of Setting Up A Rotary Kiln Cement Plant

Adapting to complex configurations of cement plants in ...

With total process control in mind, ARM needed to accurately and reliably monitor the 45 m long rotary kiln at the Kaloleni plant, to prevent any interruption in production due to hot spots and to control the burning process. Even though the kiln is relatively small, this project was a challenge because the scanner had to be set up at a very close distance from the shell – less than 10 m.

PRE FEASIBILITY REPORT Of BHAVANIPURAM

DCL was promoted by Sri and associates in 1979 to set up a mini cement plant with an installed capacity of 66000 tonnes per annum in Nalgonda District of Telangana. The company commenced it's commercial production in the year 1982. DCL was the first mini cement plant in the country to adopt the dry process Rotary Kiln Precalcinatory technology for the manufacture of .

cement rotary kiln price and cost

Rotary Kiln Cement Plant finds its appliions in the manufacturing of Portland and varied other types of hydraulic cement Our Rotary Kiln Cement Making Plant is synonymous with quality conscious and cost effective technology Rotary Kiln Cement Making Plant offered by us . Cement rotary kilncement production processCement

Project Management Plan of Vista Cement Plant Project

The Vista Cement Plant project aims to construct a new cement production plant with two production lines, each with a production capacity of 3,500 tonnes of clinker per day. The total production capacity of the plant for different kinds of cement is planned to be 10,000 tonnes. This plant will especially produce white cement because there is only one plant in Canada that produces this type of ...

2018 cost effective rotary kiln for cement production line

Modelling and optimization of a rotary kiln direct, Know More. Rotary kilns (Figure 1) are used for a range of mineral processing operations Kilns range in size from 2–6 m in diameter and can be 50–225 m long with an operating mass of up to 3000 t Two of the most common appliions are for cement production and sponge iron production Hatch has developed a proprietary onedimensional ...

project cost of setting up a rotary kiln cement plant in india

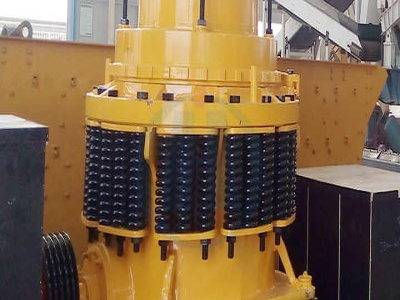

project cost of setting up a rotary kiln cement plant in india. Small cement plants in India. Small cement plants in countries Rotary Kiln Plant, VSK ... project report for building a cement plant in . HPC series cone crusher is applied to cement ... project to build a new cement plant in the ... of cement for the Burj Khalifa project, up to now the ... project cost of setting up a ...

Cement Kilns: Early rotary kilns

With rotary kilns, long uninterrupted runtimes are necessary to minimise damage to (and replacement cost of) the kiln lining, and in general to minimise operating cost. But, in addition, rotary kilns involved vastly greater capital expenditure, and high utilisation was required to pay this off at an acceptable rate. By contrast, static kilns were cheap and simple to erect with not much more ...

No: Kamalapuram (M) YSR Kadapa Dist. Dt: . Recovery ...

Line of Activity: Cement Manufacturing Unit with a project cost of Rs. 10,500 Lakhs. 2. Date of commissioning of industry: ... the industry applied for CFO to set up Waste Heat Recovery Based Power Plant of capacity MW. Date of receipt of appliion at RO Date of RO inspection Date of receipt of appliion at HO (through email) Land ...

Rotary Kiln|Cost Of Setting Up Cement Plant In Rajasthan

Industry Analysis Cement Part 2 Safal Niveshak. Jul 02 2014 8 capital cost return it takes around us 120140 per tonne to set up a cement plant this has risen from around us 100 per tonne 34 years back given the rising cost of land and its unavailability rising costs of equipment and engineering services this capital cost to set up cement capacity is only going to rise

Sustainable Waste Management: A Case Study of Cement Industry

It has been reported that the costs associated with fuels in a cement plant can be as high as 30 to 40 percent of the total production costs [6]. Recently, Central Pollution Control Board has come up with guidelines on use of Alternative fuel for Cement Industry. It will not only solve the problem of waste management to significant level but also reduce use of fossil fuel. In addition to ...

Study of a full scale oxyfuel cement rotary kiln ...

· The flow and combustion in the cement rotary kiln have been simulated using the ANSYS Fluent RANS code. The rotary kiln model dimensions have been setup according to a full scale 3000 t/d of cement with a total length of 60 m and inner diameter of m, except from the clinker sintering zone (the first 20 m from the burner end of the rotary kiln) where the coating thickness .

Rotary kiln incinerator

Photo 1: rotary kiln incinerator, boiler and a single stage (dry) flue gas treatment Photo 2: Ash chamber Photo 3: Rotary kiln Photo 4: Post combustion chamber Photo 5: Bypass chimney or emergency chimney Photo 6: Quench Photo 7: Dosing units Photo 8: Reaction chamber Photo 9: bag house filter Photo 10: ID fan Photo 11: Wet scrubber Photo 12: Chimney with CEMS platform Rotary kiln incinerator

Rotary Kiln Maintenance Procedures

save about 30% of the cost of parts obtained from kiln manufacturers. 6. Lubricants We offer a full line of kiln lubricants. Our support roller bearing oil, BearingLube, has no equal on the market today. We guarantee it to decrease the temperature of hot bearings, regardless of the cause of high temperatures. 5 Introduction The reliable maintenance of rotary kilns requires an understanding ...

Improving Performances of a Cement Rotary Kiln: A Model ...

Index Terms—cement rotary kiln, ... minimization of a cost function, it can also guarantee setpoint tracking, while monitoring control efforts [4], [5]. The control system has been developed ...

Rotary Kiln Cement Plant Cost In India

cement equipment of cement rotary dryer for sale in. 100 tpd cement plant project cost in south africa xsm rotary kiln gt 100 tpd cement plant project cost in south africa ton 100 tpd cement plant project cost in south africa ton 100 tph cement making plant video 1200 tpd cement plant cost estimates by year price 20 best mine heavy equipment operator jobs 200kg briquette machineget price.

Preheater Calciner

lowest operating cost. And thanks to a modular concept, we are able to offer just the right solution for any projectspecific requirement. No matter what production capacity, fuel concept, regional prerequisites or emission limitations, we design the best pyroprocessing solution for any appliion between 2 000 and 14 000 tpd. Preheater Calciner Preheater Calciner Overview Stage 5 Stage 4 ...

Advance Rotary Kiln Cement Plant

Advance Rotary Kiln Cement Plant. As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc. we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete plant plan.

rotary kiln of cement plant

rotary kiln of cement plant. Our company provides different types of dry process cement rotary kilns and wet process cement rotary kilns adopted in cement plants according to customers' requirements The dry process of cement is to grind raw meal into dry powder and then put it into a preheater or cement kiln for calcination

Dalmia Cement to set up cement plant at Yadwad

The project involves setting up of a Cement Plant ( MTPA), Clinker ( MTPA) and Captive Power Plant (40 MW. The unit will manufacture 42% Ordinary Portland Cement (OPC), 3% Pozzolana Portland Cement (PPC) and 55% Slag Cement (PSC) . The total project cost is estimated at Rs. 10427 million. Cement plant will be based on dry process and precalciner technology. Electrostatic precipitators ...

I L)

"projectbased" commercialscale Cement Lock® manufacturing plant is projected to require a processing fee of per "insitu" ton of sediment. This manufacturing plant would utilize a meter rotary kiln operating at 69 tons per hour with a projected average capacity of 50,000 tons per year. This facility is projected to require 4 to ...

Cost of incineration plant

· CAPEX of incineration plant Cost of incineration plant by formula. According to the formula, the cost of a 40,000 tpa plant is 41 million, or 1,026 per ton of annual capacity. A Mediumsized 250,000 tpa plant should cost 169 million, or 680 per ton of annual capacity. These numbers give us the first estimation of how much wastetoenergy is ...

Latest Posts

- الرسم البياني المسمى جيدا لآلة مطحنة الخام العمودية

- معدات لخام الحديد التعدين

- مصنع كسارة الحجر كلف مصر الجزائر

- أفضل 10 مطاحن رطبة في مصر

- صناعة سحق حجر في ولاية البنجاب

- تصنيع حجر الكسارة الصدمية في البنجاب

- مواصفات 5tph الحجر الجيري المواصفات النباتية

- معدات جرافة الرمال العمانية للبيع

- مصنع منجم خام الغابون المنجنيز

- مصانع الخيط في الولايات المتحدة

- سعر كسارة الصخور الصغيرة في السودان

- استخدام كسارات الصخور للبيع في الجزائر

- كيفية شراء الجرانيت كسارة

- مطحنة الكرة الاسمنتية المصغرة

- ملف أسعار محطات الطاقة الحرارية الحديثة

- Small Rolling Mill Bangalore In Kuwait

- Sand Crusher Related

- Diamond Mills Art

- Crusher Plant In Maharashtra Price

- Stone Crusher Flow Chart

- Small Portable Gravel Crusher In Of Malaysia

- Stone Crusher Equipment Price Ma O

- Aluminum Rolling Mill Cold

- Micro Grinding Stone Shank

- Costa Rica Suppliers Of Cement Mill Roller Press

- Iron Ore Crusher Operation Maintenance With Diagram

- Magnetic Separator Shanghai Zhongbo Machinery

- Sistem Operasi Coal Feeder

- Detail Pondasi Stone Crusher Italy Aug

- Pe Wax Grinding Machine