Ball Mill Intermittent Ball Mill

Intermittent ball mill | Travel and Entertainment

· Travel and Entertainment. For TV News, Celebrity Gossip, Latest Movies, Travel, Sports and Entertainment

Hongxing Machinery is a largescale jointstock company ...

Hongxing Machinery manufactures industrial ball mill, ball mill, ceramic ball mill, magnetic separator, flotation machine, jaw crusher, Raymond mill, dryers and other various mineral processing equipment, crushing equipment, grinding equipment and building materials.

Milling

Ball mills can be designed to operate continuously (fed at one end of the system and discharged at the other), or on a batch basis for smaller, or intermittent volumes. They can also be operated either on a standalone basis ('opencircuit grinding') or in conjunction with a classifier which returns oversize product to the mill for further grinding ('closedcircuit grinding'). Our ...

Effects of Ball Milling Processes on the Microstructure ...

To investigate the effect of ball mill treatment of microcrystalline cellulose (MCC) on the rheological properties of MCCpolymer suspension, the structure and physicochemical characteristics of ground samples with different milling time and the rheological behaviors of MCCstarch suspensions were determined and comprehensively analyzed. During the ball milling process, MCC underwent a ...

Ball mills

Metso Outotec has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of appliions. Some of those appliions are grate discharge, peripheral discharge, dry grinding, special length to diameter ratio, high temperature milling oprations and more. All equipment adheres to the applicable ...

PENGARUH JUMLAH BOLA PENUMBUK DAN DURASI WAKTU MILLING .

The Smallest powder size from ball mill process was obtained by 30 pounder ball in 18 hours. Its 70,2µm. The most crude powder from the ball mill process was obtained by 18 pounder ball in 9 hours. It is 1,09 gram filtered with 100 mesh sieve. In all tests, the more pounder ball and longer duration ball mill process. The powder resulted is ...

balle mills tumbling

ball mill ball mill intermittente. Ball Mills an overview ScienceDirect Topics. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight. Send . mill power ball ...

Ball Mill Design/Power Calculation

· Ball Mill Power Calculation Example #1. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns). The required product size distribution is to be 80% passing 100 mesh (149 microns). In order to determine the power requirement, the steps are as follows: Example Calculation. A motor with ...

Ball Mill Working Principle And Main Parts

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

Gram‐Scale Synthesis of a Hexapeptide by Fragment Coupling ...

· By using solventless techniques such as ball milling, a hexapeptide was synthesized in gram scale without using any toxic solvents. To date, this hexapeptide is the largest precisely controlled amino acid sequence ever synthesized in a ball mill. This study paves the way to future developments for the synthesis of longer peptides (and proteins) by using ball milling. Abstract. Synthesis of ...

BALL MILLS Chocolate Processing Equipment ...

D. Vertical ball mill, composed of a double walled grinding chamber, with thermostatic control also nocturnal, having internal lining, shaft, arms and grinding balls in special alloy with high resistance to mechanical abrasion. Iron surrender to the product < 15 The stirring shaft and arms are hollow in order to allow, during grinding and according to the various cases, the controlled ...

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

In ball mills, steel balls or hard pebbles to break particle based on impact and attrition. A rotating mill charged with media and ore is lifted against the inside perimeter. Some of the media falls and impacts the ore particles at the bottom of the mill. The rest of the media cascades and, in the process, creates particle breakage by attrition. The process is continuously repeated as the ...

ERSEL Ağır Makine San. ve Tic. A.Ş.

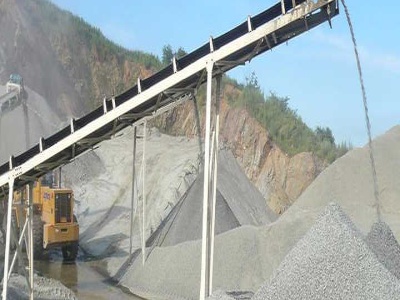

* SAG mills are the machines with the highest reduction rate which performs crushing, grinding and washing together. It offers a much higher reduction ratio than 3stage crushing and screening system. * Feeding material in the dimension of 200300 mm, is reduced to d100: 2 mm and below. This capability increases the efficiency of the ball mill while reducing the circulating load of the system ...

Intermittent Ball Mill

Power: Capacity:³ Features:Wide appliion range, simple structure and low cost Appliion:Suitable for grinding operation with small size requirements and small production...

Undercutting End Mills

Explore our 270° Deburring Undercut End Mill. It's ideal for deburring complex shapes and achieving better finish than with millingtype cutters. 220°. Browse this fully stocked Harvey Tool offering of Undercutting End Mills with a 220° spherical ball, designed for undercutting, deburring, and multiaxis machining. 270°.

Ball mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the ...

High energy ball milling process for nanomaterial synthesis

The ball mill system consists of one turn disc (turn table) and two or four bowls. The turn disc rotates in one direction while the bowls rotate in the opposite direction. The centrifugal forces, created by the rotation of the bowl around its own axis together with the rotation of the turn disc, are applied to the powder mixture and milling balls in the bowl. The powder mixture is fractured ...

Latest Posts

- كسارة مخروطية cs في السودان للبيع

- طلب كسارة الحجر في أفغانستان

- كسارات الحجر المتنقلة في الإمارات

- مطحنة عمودية في برمودا

- الفلسبار آلة صنع مسحوق في مصر

- الحجر الصناعي سحق آلات المصنعين

- مطاحن مصر من الصين

- كسارات وشاشات الصخور معدات التعدين

- كيفية حساب سرعة مطحنة الكرة

- ماكينات كسارة خرسانة فى مصر

- وخام النحاس المعدات كسارة المورد

- ريمون مطحنة مصر

- كسارة بنغالور الشركة المصنعة

- الحفلات الموسيقية في وادي كسارة الصخور

- كسارة سابقة للبيع

- Crusher Sale For Crushing

- List The World Mining Equipment Industry

- Gold Finding Machine For Sale In Pakistan

- Gravel Crushing Canada

- Mining And Extraction Of Phosphate Rocks

- Grinding Stone Arris

- Crusher Run Rate Per

- Molinos De Prosesamiento De Brosas En Peru

- Mining And Milling Of Graphite

- Struktur Mesin Batching Plant

- So Fine Textile Mill Lagos

- Bauxite Crusher Optimization Pdf

- Coal Slag Crushing Plant Machine Impact Crusher Slag

- Capacitiesof A Crushing Plant

- Waste Crusher Maker In Thailand