2 Sizer Stages Iron Ore Processing Plant

Document No EW5203

Ore Preparation Ore Sizer 8 Process Description 8 Operating Philosophy 9 Reliability 9 Duty and Throughput Rate 9 Equipment Design Life 9 Other 9 Lifting Lugs 9 Noise Level 9 Safety Guards 9 6 DETAILED TECHNICAL REQUIREMENTS 10 SNCLAVALIN EW5203_0A Ore . Page SCOPE OF WORK ORE SIZER .

Araguaia, Brazil's next major Ferronickel Project

Run of Mine (ROM) ore, at an average moisture content of 34%, is first blended to meet metallurgical processing requirements, then transported to the primary crushing stage. Here the ore is sized using two stages of crushing to match the requirements of the subsequent steps. A mineral sizer with a 200 mm gap is used for primary sizing, while a mineral sizer with a 50 mm gap is used for the ...

Metallurgical Processing of PolyMet's NorthMet Deposit

Steel Mining Company taconite iron ore processing plant which is loed about 7 miles from the NorthMet deposit. The plant and associated mining operations were closed in early 2001 due to bankruptcy and at its peak, this plant processed over 90,000 long tons/ day of taconite iron ore via a four stage crushing, grinding and flotation process. PolyMet is now the owner of this plant (purchase ...

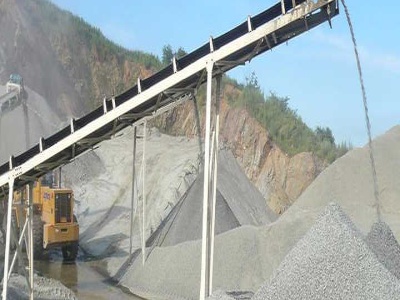

stages iron ore processing plant

When the iron ore is extracted from the mine, it must undergo several processing stages. Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher's CSS before the crushing stage . More. Iron Ore Processing,Crushing,Grinding Plant Machine . Based on the iron ore processing experience and .

Our Operations | Fortescue Metals Group Ltd

As one of the world's largest producers of iron ore, Fortescue's wholly owned and integrated operations in the Pilbara include the Chichester, Solomon and Western mining hubs. Our mining infrastructure is connected to the five berth Herb Elliott Port and Judith Street Harbour towage facility in Port Hedland via the fastest heavy haul railway in the world. Chichester Hub . Our Chichester ...

Fomento Group CEO reveals expansion plan, jobs for ...

· iron ore mining australia generic The next big development will be in roughly a year and a half when Fomento will develop its central processing plant for the mines.

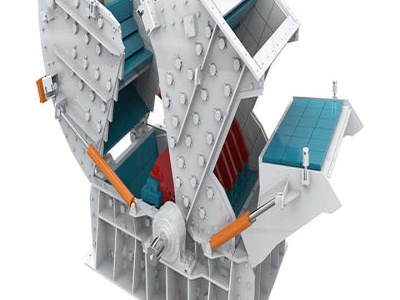

(PDF) SIZE REDUCTION BY CRUSHING METHODS

tool for improvement of the size fractions in the process stages and ... II) has % % of Tin (Sn) and % % of Iron II oxide (Fe2O3). Conclusively, an understanding of the ...

JWD Iron Ore Project

A mobile crushing and screening plant is proposed to process the Million tonnes (Mt) of iron ore mined over stages 1,2 and 3 of the Project via conventional drill and blast and load and haul mining practises. The crushing and screening plant will be loed adjacent to the runofmine (ROM) within

Steelmaking Process V8 CMYK

The steelmaking process Two main routes OUTPUT PRODUCTS Direct reduction of iron ore Blast furnace Sinter plant / Pellet plant Coke oven Refining Continuous casting Electric arc furnace Electricity Oxygen Basic oxygen furnace Supplementary heating fuels Wind turbines Buildings Packaging Ships containers Motor vehicles Plant / Machinery Bridges Factories White goods Razor blades Rail tracks ...

roll sizer load calculation « BINQ Mining

> Ore Process > roll sizer load calculation; Print. roll sizer load calculation. Posted at:June 10, 2013[ 2883 Ratings] detailed calculation of capacity and power of a roll crusher. This page is about detailed calculation of capacity and power of . »More detailed. PDF ( ) – SMS Meer . Pass size calculaTion: . Specific modules calculate the pass size of rolls . load. Different ro

Amendment Notice 1

Stage 1 – widening of embankment 1 from the eastern end to the final process plant 1 tailings spigot, and raising the Southern Ramp to a minimum crest of metres above ground level. Stage 2 – raising of embankment 2 to metres above ground level and raising embankment 4 to a minimum crest of metres above ground level.

Copper recovery using leach/solvent extraction ...

low quality copper from the leach solution on scrap iron, was practiced on oxide ore that was too lowgrade for vat leaching, or low grade sulphide ore that had to be mined in order to expose the underlying high grade sulfide ore. Copper recovered from leaching low grade copper ores was considered a bonus and little effort had been made to fully understand the leaching process or to maximize ...

Ore processing

· Stage 2: Ore Washing Plant; Stage 3: Thermal Centrifuge; Stage 1. A Macerator processes ore iron, gold, copper, tin, lead, and uranium into 2x crushed ore of the corresponding type. It does not process (as of ) ores for coal, lapis, diamond, redstone, emerald, or nether quartz. Crushed ore can be smelted into ingots (except for uranium). Stage 2. An Ore .

Industries

such as iron ore, coal and limestone, along with labour, capital, site and other infrastructure. The process of converting iron ore into steel involves many stages. The raw material is put in the blast furnace where it undergoes smelting (Fig ). It is then refined. The output obtained is steel which may be used by other industries as raw ...

Processing Stages Of Iron Ore

hydrogen plasma processing of iron ore. kali charan sabat and anthony b. murphy. iron is currently produced by carbothermic reduction of oxide ores. this is a multiplestage. and processing of iron ore slimes for,(2015). characterization and processing of iron ore slimes for recovery of iron values. mineral processing and extractive metallurgy review: vol. 36, no. 3 ...

NMDC Limited

For Value addition NMDC is in the process of developing a 3 mtpa steel plant at Jagdalpur and 2 pellet plants at Donimalai ( mtpa) and at Bacheli (2 mtpa). Besides, NMDC has acquired Sponge Iron India Limited with plan for expansion to produce billets. Besides iron ore, NMDC also plans to go for other minerals like Coal, Diamond, gold etc for which NMDC is looking forward for leases / buy ...

Infographic: the Iron and Steel Manufacturing Process

· An Infographic of the Iron and Steel Manufacturing Process. Steel production is a 24houraday, 365dayayear process, dependent on a consistent supply of raw materials and huge amounts of energy. According to the World Steel Association, world crude steel production has increased from 851 million tonnes (Mt) in 2001 to 1,606 Mt in 2013 and ...

Steelmaking CO2 carbon dioxide emissions by process step

The main process steps that generate carbon dioxide in iron and steelmaking are the production of coke, and the production of hot metal in the blast furnace. Ancillary facilities such as power plants also produce large volume of CO2. The table below identifies typical CO2 production volumes per tonne of output for each steelmaking process stage. Figures show are for typical steel plants in the ...

How to Smelt Iron: The 6 Steps to Iron Smelting | The ...

Smelting is the process of extracting base metals from ore by heating it to produce the chemical reactions needed to remove the other elements present. This article will walk through how The Crucible produced their own iron through the smelting of iron ore. First, let's start with understanding the basics. What is iron ore? Iron ores are rocks and minerals rich in iron oxide that can produce ...

Sishen Mine, Northern Cape, South Africa

Mining and processing of iron ore. The Sishen mine employs the openpit mining method involving drill and blast. The mined ore is trucked to the nearby beneficiation plant. The mine uses a fleet of P shovels and 960 trucks. Strong performance of the 2,800 shovel fleet in 2019 allowed the mine to exceed equipment efficiency targets. The owner fleet efficiency of the mining operation ...

sizer stages iron ore processing plant

2 sizer stages iron ore processing plant. AMIT 145 Lesson 4 Gravity Separation Mining Mill . Operator/Plant Loion Mineral Processed Size Range Plant Feed tph HMS Units Sink/Float Ratio Separation Density; Aluminum Co. od Canada, Ltd. St. Lawrence, Newfoundland Flourspar Barites3/4 20M 80 215 40/60 Barton Mines North Creek, NY Garnets1/4 45M 60 112 19 60/40 .

Latest Posts

- صنع الرمال عملية جافة عملية رطبة

- محاجر الجرانيت في ولاية كارناتاكا للبيع

- الحصى سحق camilecrusher

- مطحنة ريمون مطحنة آلة 3r

- آلات طحن الشركة المصنعة

- عالية الكفاءة تأثير محطم الغيار المصنوعة في الصين

- مورد الأحجار المسحوقة في rustenburg

- تكلفة مصنع الحديد الإسفنجي في مصر

- تكلفة صخرة الرمل مصر

- يوحد م آلات الرمل المستخدمة

- أماكن معادن ميكا في الأردن

- الدولوميت آلة سحق بيع مصر

- عروض الصين

- كسارة الفك backenbrec no

- كسارة الحجر 50 tph في andrapradesh

- Gold Mining Equipment Jaw Crusher

- China Atta Chakki Machine

- Indonesia Crusher Mobile Crusher Philippines Page

- Cone Crusherbination Machinejaw Crusher Manufacturer Georgia

- Gyratory Or Jaw Crusher

- Roller Mills Manufacturer In Botswana

- Concept Behind Ball Milling

- Next List Of Girni Kamgar

- Gold Portable Equipment Manufacturer In South Africa

- Cnc Lathe Machine Carbon Steel Hydraulic Motor Components

- Ultra Table Top Wet Grinder Service Centre In Dubai

- Milling Machines Turkish

- Bucket Crushers Supplier

- Sertifikat Halal Silica Sand Ex Bangka

- Mobile Crushing Equipment Supplier