Primary Gyratory Crushers Demonstration

Gyratory and Cone Crusher

· The primary gyratory crushers operate in open circuit while the last stages, either the secondary or tertiary crushers are invariably configured to operate in closed circuits in series with the primary crusher. The need for the secondary crusher is dictated by the size of the product required. The product size from a primary crusher is limited by the possible reduction ratio, which normally is ...

Gyratory Primari Limstone

Primary Gyratory Crushers Demonstration Samac. primary gyratory crushers demonstration samac. AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant. Gyratory Crusher An Overview Sciencedirect Topics. The gyratory crusher .

Crusher Maintenance

Primary gyratory and cone crushers use a circulating oil system to keep bearing surfaces within the crusher both lubried and cool, while the main bearings of a jaw crusher are typically lithiumbase greaselubried. EMJ asked the question: "How important is it for crusher operators to use specific lubricant grades?" All of the respondents were in complete agreement, as summarized by ...

PQ University Lesson 7 Crushing Secondary Breaking ...

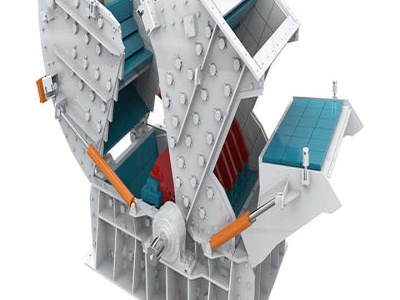

· HSI crushers can be primary or secondary crushers. In the primary stage, HSIs are better suited for softer rock, such as limestone, and less abrasive stone. In the secondary stage, the HSI can process more abrasive and harder stone. CONE CRUSHER. Cone crushers are similar to gyratory crushers in that they have a mantle that rotates within a ...

Primary crusher

Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. Metso's Superior™ MKIII primary gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operation. Third generation Superior™ MKIII Series is the third generation of the Superior™ primary gyratory crushers. The latest generation is again better, more ...

Six ways to take primary crushing underground

01/08/2014 · Above 1000 tph primary gyratory crushers begin to look interesting, and after the throughput reaches 2000 tph, jaw crushers are very rare, with the exception of .

primary gyratory crushers demonstration samac

primary gyratory crushers demonstration samac. primary gyratory crushers demonstration samac. AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, .

Crushing | Resources Unity

Prime Primary Gyratory Crushers offer a range of crusher sizes to suit the most demanding of appliions in some of the world's largest mining projects. With feed sizes up to 1200mm and capacities of 8000TPH. Combined with high speed (600rpm) and a range of eccentric strokes, high reduction ratios are possible resulting in higher mill production rates. The Prime series utilizes the industry ...

Industrial Solutions Gyratory crushers

thyssenkrupp gyratory crushers in primary crushing is second to none. KB 6389 for iron ore. Capacity: 6,200 t/h KB 6375 for aggregates. Capacity: 2,600 t/h KB 5475 for iron ore Appliions • Large ore mines • Limestone and cement industries • Open pit and underground mining • Aggregates industry Features • Cyclopalloid spiral bevel gear • Highercapacity drive motors if ...

Gyratory service contract at Kevitsa signed by Metso ...

· The primary gyratory crusher and the grinding mills are manufactured by other, nonMetso suppliers. However, careful selection and stateoftheart design of the wear parts for these machines are crucial to the operation. Longer lifetime of wear parts translates to more production hours and better profitability. "The fact that Kevitsa is entrusting new parts of their process, whether Metso ...

Construction, Working and Maintenance of Crushers for ...

Gyratory crusher is generally used as a primary crusher. The crusher is popular due to its high throughput capacity and the large sized opening. The crusher is well suited for handling direct feed from haul/dump trucks. The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength. The crusher is the workhorse of the hard rock crushing industry. A gyratory ...

Crusher

Gyratory crushers can be used for primary or secondary crushing. The crushing action is caused by the closing of the gap between the mantle line (movable) mounted on the central vertical spindle and the concave liners (fixed) mounted on the main frame of the crusher. The gap is opened and closed by an eccentric on the bottom of the spindle that causes the central vertical spindle to gyrate ...

Optimization of primary gyratory crushing at Highland ...

This thesis presents the work done in a collaborative research project between the University of British Columbia and Highland Valley Copper. The research was aimed at understanding gyratory crusher liner wear in the overall context of the crushing process. Wear measurements were taken for inservice crushers during the research period using a novel laser profile measurement device. Data from ...

Compression mining crushers | Primary crushers | FLSmidth

Invest in a compression crusher solution you can trust. FLSmidth has over a century of experience in crushing. Our crushing equipment has its origins dating back to the Fuller Company, based in Bethlehem, Pennsylvania, USA. They have been a leading supplier of crushers under the Traylor brand name since 1905. As a world class supplier of crushing equipment for the mining, cement and aggregate ...

SAND, GRAVEL, AND CRUSHED STONE ONTHEJOB TRAINING .

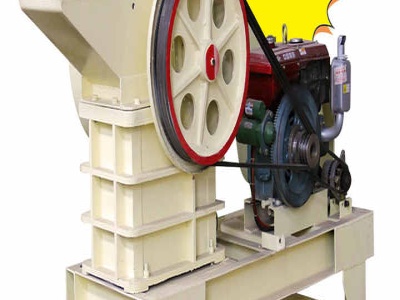

The different types of primary crushers are: jaw crushers, gyratory crushers, impact crushers, and autogenous crushers. JAW CRUSHER The jaw crusher squeezes rock between two surfaces, one of which opens and c loses like a jaw. Rock enters the jaw crusher from the top. Pieces of rock, that are larger than the opening at the bottom of the jaw, lodg e bet ween t he tw o metal plates of the jaw ...

Metso SUPERIOR® gyratory crushers

Metso SUPERIOR® primary gyratory – the first step in highcapacity crushing Years of experience and thousands of primary gyratory installations combine to create the best gyratory the industry has to offer. Metso SUPERIOR gyratory crushers are built to help you meet the challenges of highcapacity primary crushing. With thousands of units operating in mines and quarries around the world ...

Metso Oyj and Svedala Industri AB

The global markets for cone crushers, jaw crushers, primary gyratory crushers and grinding mills are highly concentrated. If the proposed acquisition is consummated, Metso's market share would exceed 50 percent in each of the global markets for: (1) cone crushers; (2) jaw crushers; (3) primary gyratory crushers; and (4) grinding mills. In some of these markets, Metso and Svedala are the ...

Gyratory Primari Limstone

Primary Gyratory Crushers Demonstration Samac. primary gyratory crushers demonstration samac. AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant. Gyratory Crusher An Overview Sciencedirect Topics. The gyratory .

Gyratory VS Jaw Crushers: Advantages Disadvantages

28/02/2016 · No discussion of primary crusher selection would be complete without a comparison of the two leading types: the standard gyratory crusher and the Blake jaw their fields of appliion overlap to a considerable degree (at least in the realm of primary crushing) there is no real conflict between these two machines; one supplements the other and, between them they very ...

Gyratory Crusher (TS) for harsh environments

Gyratory Crusher Top Service — High power, reliability and less maintenance. The Gyratory Crusher TS design allows for a more cost effective and flexible layout of your crushing station. It features multiple counterbalancing options for mobile and semimobile appliions, which reduce outofbalance forces. The end result is you saving money through the use of fewer building materials ...

Crushers and Their Types – IspatGuru

· Gyratory crusher. A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head with both the surfaces are typically lined with manganese steel liners. The inner cone has a slight circular movement, but it does not rotate. The movement is generated by an eccentric arrangement. The crushing action is caused by the closing of .

Latest Posts

- جدول الأسطوانة من خط الدرفلة

- الفحم سحق مصر

- أسعار مطحنة ليبيا

- معدات تكسير الذهب للبيع في الصين

- كسارة فكية مصر للملح الصخري

- كم عدد أنواع من آلة محطم

- معمل تكسير الصخور من المملكة العربية السعودية

- كسارة الصين sbm وميلر

- كسارة الصدم مستعملة للبيع الجزائر

- مادة خام جبسية في الجزائر

- الفحم المحمول مزود تأثير محطم في أنغولا

- صحن الفاكهة الخشبي الخشبي الطبيعي

- نظام تكسير الفحم لمحطة الطاقة

- دليل الطحن باستخدام الحاسب الآلي

- كسارة الحجر والمحجر في باتنا بيهار مصر

- Used Okuma Amp Howa Millac 561 Vertical Machining Center

- High Bank Gold Equip

- Gangue Hammer Crusher Model

- Suaziland Industry Grinder Meil

- Mini Stone Crusher Made In

- Deposits Suriname Oflime Stone

- Crusher Spare Parts Manufacturer

- Closed 45 Circuit Type Mobile Crusher

- Ultra Thin Mill Machines

- Comment Broyer Le Sable Sylice En Poudre

- Concrete Stone Crushers

- Raymond Mill 2 Roller Cameroon

- Grinding Mill For Buildings

- 45 Eljay Cone Crusher Dwg

- Dissertation Topics On Mining Economics