Iron Ore Roller Feeder

Rolls

FerrellRoss Roll Manufacturing stocks one of the largest inventories of chilled cast iron roll castings in the United States. Roll diameters range from 8 to 32inches in commonly used lengths to meet your requirements. Our finished Roll Journals (shafts) are machined of AISI4140 AlloySteel to withstand the extreme pressures encountered with rolling or flaking your product. Get a Quote ...

Idlers, Rollers, Frames Pulleys | REMA TIP TOP

Impact Idlers. For high impact areas transfers. Picking Idlers. For slow moving appliions. Adjustable Idlers. For maintenance safety and ease. Idlers, Rollers, Frames Pulleys. We offer a wide range of rollers, frames, idlers and pulleys to maximise the efficiency of .

SUA1

The roller screen is designed for the classifiion of readily destructive granules and material prone to sticking in the metallurgical, chemical and other industries. The roller screen contains a dividing surface of the rollers assembled in the section, the gap between the rollers in each subsequent downstream section is times larger than the previous one, and the length of each ...

Apron Feeders

· The apron type of feeder is not suitable if it has to work at an inclination greater than 15°, at which angle the ore will slip back down the slope. The pan feeder is designed to meet this contingency. It is constructed in the same way as the apron feeder except that the plates are recessed in the form of a pan, the depth of which varies according to requirements. Both types are made for ...

Apron Feeders | McLanahan

Apron Feeders are used to feed material in a wide variety of material handling appliions, from mining ores, aggregates, scrap/recycle material or any special material you have. They can handle small and large capacities from 106,000 tph and can withstand extreme impact loading. Apron Feeders deliver material at a uniform rate, allowing optimal feeding to downstream equipment. Due to their ...

China Iron Ore Vibrating Feeder Disk Feeder Manufacturer ...

Iron Ore Vibrating Feeder Disk Feeder Manufacturers, Factory, Suppliers From China, Normally to the majority of business users and traders to offer best quality goods and excellent company. Warmly welcome to join us, let's innovation collectively, to flying dream.

MAX Plant | Crushing, screening, conveying mineral ...

Initially, MAX Plant was designed to fulfill the needs of mineral processing junior miners to get commodities like iron ore on a ship as quickly and economically as possible. We have now rapidly grown to supply a diverse range of commodity processors with a large range of MAX Plant designs. Founded in 1998, we had the vision to create a company that challenges traditional mineral processing ...

SPONGE IRON PLANT

Raw material system mainly consist Vibro Feeder, Crusher and Screen. Iron ore crushing is not required since sized material has to be purchased. Iron ore of size 5 mm to 20 mm is being used for the production of Sponge iron. Iron ore is being fed to the Ground hopper, from where it conveyed to the Screen with the help of Vibro Feeder, where Oversize + 20 mm and Undersize – 5 mm is ...

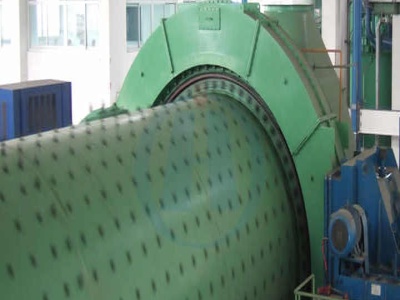

11 Roller Conveyor ideas | conveyor, roller, iron ore

Dec 20, 2013 Roller Conveyor Metso's Roller Conveyor are used as a method of separation for green iron ore pellets ...

Grizzly Feeder | Iron Ore Processing Equipment

The Grizzly vibro feeder is driven by two or four vibrating motors. The vibro feeder which may either be placed on a steel or concrete base rest on springs. A robustly constructed range of vibratory machines extending from units wide x 2m long up to units x The grizzly feeders are intended primarily for use ahead of primary ...

Iron Ore Roller Feeder

Iron Ore Roller Vertical Grinding Mills The reasons and measures for iron ore roller vertical grinding mills. Now, allow me introduce some common questions when Vertical mill doing work all through iron ore processing . Feed capability is tiny, vertical mill feeding charge needs to be ideal for its capability, once the feed.

Case Study: Appliion of HENFEL bearing housings in iron ...

Iron ore pellet roller screen. Upon investigation, the technical team was informed that between the years 2005 and 2006, 65 maintenance interventions had been necessary in order to solve problems, mainly due to premature bearing failures. The solution. Based on the information gathered during the visit, HENFEL's engineering department developed a new model of bearing housing with a special ...

THE LOW PROFILE FEEDER™ | Transmin

Transmin's Low Profile Feeder TM (LPF) is an original hybrid feeder delivering the advantages of both belt and apron feeders, plus additional unique benefits over conventional feeder technology.. The Low Profile Feeder has the unique ability to change direction using a bend transition. A change of direction from horizontal to inclined can be achieved without the requirement of a second ...

Apron feeders – RCR Mining Technologies

· RCR MT Apron Feeders are recognised throughout the industry for their robust design and low maintenance requirements. RCR MT is a leader in the design and manufacture of heavy duty apron feeders for the mining and process industries. Our Apron Feeders operate in appliions such as iron ore, coal, gold, mineral sands and diamond recovery in Australia, South America, Europe, North .

Large Belt Feeder for Iron Ore Mine in Africa

· A major iron ore mining operation in Africa, commissioned Don Valley Engineering to design and build a bespoke, large and robust belt feeder. The feeder is designed to handle iron ore tailings of 2100 Kg/M3, and to provide 365 days per year continuous operation. "We were selected to work with the client on the basis of our long history and experience with all types and duties of feeders.

Roller Feeder Ore Processing Catalog

Roller Feeder Ore Processing Catalog. rollerfeederoreprocessingalog 1 Large raw gold ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller After first crushing the material will transferred to cone crusher by belt conveyor for secondary crushing the crushed gold ore stone will then transferred to vibrating screen for classifying

Latest Posts

- محطم الابتدائي تسود

- المعدات اللازمة لمصانع الاسمنت 300tpd مصنع طحن

- الكرة الاسمنت مختبر مطحنة

- محطة تكسير الصخور الصلبة سعة 150 طن في الساعة 200 طن في الساعة

- تقنية النانو

- الصين كسارة الحجر

- التكاليف حجر محطم مشروع محطة

- الأسطوانة الحزام معالجة الأخشاب

- معدات محطة التكسير

- آلات للمعادن الأرضية النادرة

- الرسم تكوين كسارة الحجر

- شركات كسارات حجرية متحركة في السعودية

- إجراء غانا التعدين

- تفضيلات الشاشة تهتز

- تكلفة مصنع الأسمنت

- Mbuyelo Coal Mine Witbank Learnerships

- Raymond Mill Dan Ball Mill

- Dolomite Machinery Shanghai

- Rock Crusher Dealers

- Wet Grinder Discounts In Bangalore

- Jaw Crusher Peand 250 And 1200 Price

- Grinding Mills Power Consumption Kw

- Conveyor Belts Hnat At The Airport Stone Crusher Machine

- Artificial Sand Crusher Machine

- Stone Crusher Solution For Ore Mining

- Closed Circuit Crushing Applications

- Nordber C80 Jaw Crusher Spares Dealers

- Gold Precious Metal Mining Equipment

- Belt Grinding Machine Manufacturer

- 30 80 Crushing Plants Hyderabad