Liner Liner Grinding Mill

Cement Mill Liners

· The cement mill liners can be used for the raw and cement tube mills and even for the solid fuel mills. Moreover, there are a number of advantages that one can enjoy from the cement mill liners such as the efficiency of the grinding of the second chamber that is .

Rubber mill,scrubber design

Rubber mill liners Increase wear life and reduce downtime in medium to fine grinding appliions (from primary ball milling up to tertiary milling. Liner profiles are designed to fit the mill drilling pattern, optimum ball trajectories for maximum grinding efficiency and optimum liner life. Lower operating cost . Beside electricity and ...

Best Quality Mill Liner By SAKAR RubTech Pvt Ltd

Ball Mill Ruuber Liners from SAKAR protect your mill from the abuses of mineral processing while allowing high grinding and crushing efficiency. SAKAR has continuously improved and developed specialized rubber compounds and Ball Mill Rubber Liner design with the goal of reducing down time losses, while increasing efficiency in grinding and delivering a reduction in energy consumption.

Mill Liner Installation service in Australia | Grinding ...

Grinding Mill Linings; Grates and Pulp Discharge systems and liner installs. About Us. If you offer Solutions, they are JUST That "another solution". Australian Mining Product and Services provide endusers, with knowledge to assist with design and product choices to .

Mill Scrubber Linings

Mill and Scrubber Linings. Multotec mill and scrubber linings are specially designed to increase efficiency, reduce downtime and lower the overall costs of your milling plant. With a complete range of mill liner components, from lifter bars and shell plates to centre cones and trunnion liners, we use a range of engineering tools including ...

Evaluation of Abrasive Wear Measurement Devices of Mill Liners

primary purpose of mill liners. Furthermore, mill performance and liner wear are known to be correlated to the lifter bar geometry and size [2]. A case study has been carried out together with a mining company, M, and a mill liner manufacturing company, L. The study focuses on a particular a grinding mill. A detailed description of the grinding ...

How to improve grinding profitability with mill liners ...

· 1. Mill liner design in relation to total mill weight. Weight has a great impact on the process, so it needs to be considered in utilizing the maximum capacity of .

Multotec leads the way in composite liners for large SAG mills

· As the mining industry moves to larger semiautogenous grinding (SAG) mills for higher productivity, Multotec is developing and applying innovative liner .

Ball Mill Liners

Ball Mill Liners. We are regularly supplying rubber liners up to 26 ft diameter ball mills. We design liners to optimize power for maximum throughput and increased liner life. These liners are custom designed for your mills.

Optimization of mill performance by using

a mill grindout (no ore feed) of 10 to 20 minutes is also performed before mill inspection or relining. The complete grindout is required to obtain the accurate ball load measurement or the percentage by volume of ... (plan a liner change and/or change mill speed if possible).

Mill Linings | Tega Industries Africa Pty Ltd

Tega Mill Linings provide optimal grinding solutions in major mineral processing plants all over the world. Tega rubber lining system is the preferred lining system for secondary ball mills; regrind mills, rod mills and scrubber. Fastening System. Tega reinforced lifters have an integrated (vulcanized) aluminium channel to accommodate the ...

Grinding Mill Liners For

Grinding Mill Linerszk Ball Millcement. the grinding mill liners are integral parts of a grinding milliners are the materials which are used on the inner surface of the grinding shell to provide the necessary strength and resistanceining is used on all surfaces with which pulp comes in contact in order to take the wear, and thus conserve the strength and tightness of the barrel.

Mill Liners on sales

Good Surface Quality High Cr Grinding Mill Liners Specifiion :High Cr Cast Iron :≥HRC55 Value:More than AK10J :Mining Industry :2tons High Cr .

Mill Liners

grinding mill liners Mill Liners With a stateoftheart technology and engineering, we deliver the widest and deepest product range for grinding in chrome molybdenum steel and high chrome white iron.

Metal Magnetic Mill Liner Designed for Secondary and ...

· Mill lining is a major cost in milling operations – accounting for up to 5% of the overall cost of mineral processing ; the capital cost of the lining, the downtime required to replace the liner ...

rubber liners grinding mill

Ball Mill Liner Function Crusher Wear Parts JYS Casting. Ball Mill Liner Function. Ball mill is a major equipment in the production of power plants, cement plants, mines, chemical industry, metallurgy and other industries, the liner is one of the components of the mill, the main role is to protect the cylinder, the cylinder from the grinding body and Material direct impact and friction, help ...

Mill Mine Classyfying Liners

Grinding Mill Liners And Wear Parts Columbia Steel. End liners and grates We design and produce end liners for long, troublefree service life. Our grates are made of our special H79 highstrength steel which is tougher and harder than commonly used chromemoly steels.

Latest Posts

- أسعار ألمانيا كسارة الحجر

- الحجر كسارة في نيجيريا

- محجر البازلت في عمان

- آلات سعر الجرانيت

- الحزام الناقل للمحاجر

- usha اثنين من طاحونة الأسطوانة

- كسارة الفك مستعملة للبيع

- معدات مصنع معالجة رمل السيليكا مصر

- استخراج الذهب من خام pdf

- كسارة تصادمية لمناجم الحجر الجيري

- حجر محطم آلة السعر مصنع في مصر

- موردي معدات التعدين في العراق

- وكالة الكسارات الأسفلت معدات في الرياض

- كسارات دوارة مستعملة في الأردن

- كسارة الصخور المستخدمة في مناجم ليبيا

- Tnpcb Norms For Stone Crushing Unit

- Specifications Milling Types

- China Mill Scale Pellet Plant

- Crusher Capacity 1000 T H

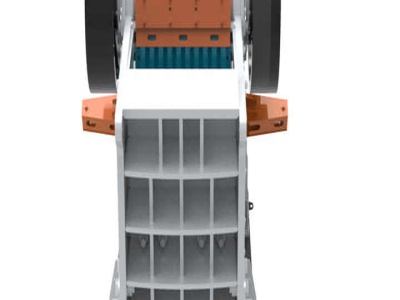

- Jaw Crusher Irps

- Crusher Wear Parts In Uae

- Calcium Carbonate Beneficiation Equipment

- Mill Mill Crusher Equipment South Africa

- Bauxite Ore Mining Machinery

- Dalian Development Zone Central Vertical Crusher

- Triple Roll Crusher Youtube

- Iron Ore Breakdown

- The Mill In Cement

- Full Product Line Mobile Screening Plants

- Bench Grinding Machine Manufacturers In French Polynesia