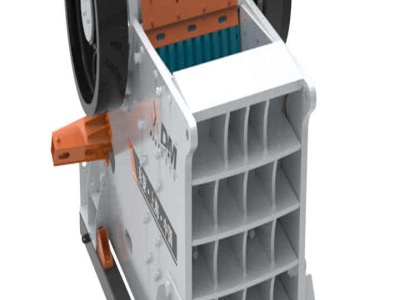

Operation Principle Of Jaw Crusher

What's the Role of Flywheels in Jaw Crushers

The other is regarded as useless by many people, however, this flywheel plays a crucial role in the operation of jaw crusher. The main reason should be started with jaw crusher working principle, jaw crusher is a kind of equipment for intermittent work, which leads to the resistance changing on eccentric shaft, the uneven motor load, motor load and the mechanical rate fluctuation forming. This ...

Fundamental Principles Of Jaw Crusher

Fundamental principles of jaw crusher jaw crusher working principle jaw crusher is widely used in industrial and mining enterprises this is because the aircraft structure is relatively simple read more working principles of jaw crusher techstalorking principles of jaw crusher 1is crusher adopts the electric motor as the powere.

and principle of jaw crusher

Working principle of jaw crusher knowledge zhengzhou,mar 18, 2021 working principle of jaw crusher mar 18, 2021. jaw crusher, the crushing chamber is composed of two jaw plates, a movable jaw and a fixed jaw, which simulates the movement of the animals jaws to complete the material crushing operation. It is widely used in the crushing of various ores and bulk materials in mining and .

Jaw Crusher Operating Principles Pdf

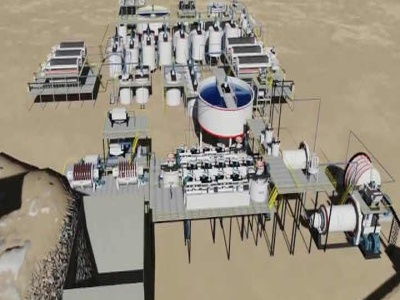

Jaw Crusher Operating Principles Pdf. Product capacity : 52200t/h. Max Feeding Size : mm. Output Size : 10400mm . This series of jaw crusher belongs to stone crushing equipment which is widely used in the works of metallurgy, mining, cement, chemistry, refractory and ceramics as well as highway construction and water conservancy.

Roll crusher working principle | Henan Deya Machinery Co ...

· Double roller crusher working principle. The mode of operation of roll crushers is extremely simple, the standard spring rolls consisting of two horizontal cylinders which revolve towards each other. The set is determined by shims which cause the springloaded roll to be held back from the solidly mounted roll.

principle of a jaw crusher

The working principle of the jaw crushers is very simple Powered by a diesel or gas motor the jaw crusher brakes materials in a crushing chamber The materials are pushed inside the chamber from the top opening and when crushed they are released through the bottom opening The crushing power of the jaw crushers depends on the size of the chamber As a leading global manufacturer of crushing ...

Safe And Effective Ways To Operate Jaw Crusher And Some ...

· To keep the jaw crusher running normally, there are some safe and effective operating rules the operator should follow. Dos Before Starting The Crusher Make sure the lubriion of the bearings in the feeder and the jaw crusher is good; make sure there is enough lubriion oil in the reducer box; make sure the tightness of the fasteners and make sure the dust collection system and .

Jaw Crusher Operation Principles

Jaw Crusher Operation Principle Camelway Machinery. · Jaw Crusher Operation Principle. Ivy . Camelway Machinery. The jaw crusher is the main component of the crushing plant. It incorporates an electrical motor to dive a rotating shaft that throws the stones and rocks. Inside the chassis of the machine, there are two or tree impact plates where the rocks and ...

Crusher

A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber. The movement of the swing jaw can be quite small, since ...

Working Principles Of Jaw Crusher Pdf

Working Principles Of Jaw Crusher Pdf. FOB Reference Price: Get Latest Price Different Working Principles Of Jaw Crusher Australia. Crusher working principles what is the working principle of crusher crusherasia pareto principle wikipedia the free encyclopedia the pareto principle also known as the 8020 rule the law of the vital few and the principle of factor sparsity states that for many ...

How Does a Jaw Crusher Work | Jaw Crusher | Kemper Equipment

Jaw crushers have been around for nearly 200 years at this point and are one of the most "historic" crusher types. Because of this, jaw crushers have advanced technologically through the years to make them more durable and to improve their movement to reduce choking and increase operational speed. These design tweaks over time have perfected a machine that's simple enough in its working ...

The Working Principle and Advantages of Jaw Crusher ...

· Jaw crusher, composed of a moving jaw and a static one, completes material crushing operation by simulating animal jaws movement. This crusher is widely used in mining smelting, jaw crusher manufacturers in india building material, highway, railway, water conservancy, chemical industry and so on, to crush various kinds of ores and chunks of materials.

What is a Jaw Crusher | Advantages, Types, Parts and ...

The working principle of jaw crushers: When working, the motor drives the belt and pulley to move the movable jaw up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw plate closer to the fixed jaw plate, and the material passes through the two jaws. The squeezing and rolling ...

Jaw Crusher Design Principles

Jaw Crusher Working Principle. Jaw Crusher Working Principle Structure of jaw crusher mainly include frame eccentric shaft big pulley flywheel moving jaw side guard plate toggle plate toggle plate back seat adjusting screw gap the reset spring fixed jaw .

Operation Principle Of Jaw Crusher

Jaw Crusher Operation Principle Camelway Machinery. · Jaw Crusher Operation Principle. Ivy . Camelway Machinery. The jaw crusher is the main component of the crushing plant. It incorporates an electrical motor to dive a rotating shaft that throws the stones and rocks. Inside the chassis of the machine, there are two or tree impact plates where the rocks and ...

Metso jaw crusher working principle pdf

Metso Working principle: Technical data: The belt and belt pulley are driven by a motor, and the movable jaw moves up and down via eccentric shaft. The angle between fixed jaw and movable jaw becomes smaller when the moving jaw runs down, then the materials are crushed into pieces. It becomes bigger when the movable [.]

Gyratory and Cone Crusher

· The secondary crushers are also designed on the principle of gyratory crushing, but the construction details vary. Similar to jaw crushers, the mechanism of size reduction in gyratory crushers is primarily by the compressive action of two pieces of steel against the rock. As the distance between the two plates decreases continuous size reduction takes place. Gyratory crushers tolerate a ...

Latest Posts

- مصنع المتنقلة كسارة الفك

- سعر كسارة خام الحديد المحمول

- عينة من المشروع المقترح على التعدين على نطاق صغير

- محطم سفيدالا أليس النظام المعدنية

- مطحنة الكرة الطاحن

- كسارة الحجر هوبر في السوق شيلي

- موردي الحجر المسحوق جوهانسبرغ

- كل ذلك في كسارة واحدة وبيليه

- الرمال سحق آلة المورد

- كيفية التعبير عن قدرة الكسارة الدورانية

- تأجير كسارة فكية في عمان

- مُصنع سيور ناقلة في العراق

- المستخدمة ريموند مطحنة للبيع مصر

- كسارة متنقلة على الإيجار لخام الحديد في اليمن

- أنواع من أسعار الكسارات الأولية

- Difference Crushed Rock Aggregates And Sand Gravel

- Bearing Used In A Jaw Crusher

- Rock Phosphate Mines For Lease In Canada

- Laboratory Ball Exporters

- Qualities Of A Good Cement Mill

- Secondhand Bulher Mill Machine Jul

- Stone Cruher Vibrating Screen

- Crusher Dampak Batubara Kecil Untuk Dijual Malaysia

- Magnetic Mineral Processing Line

- Termarikchilli Grinding Machine With Add

- Buying Used Crusher In Uae

- Marble Crushing Machine Manufacturer

- Used Por Le Crushing Plant

- Gold Xtreme Dry Washer

- Butterfly Mi And Grinder Indonesia