Mechanical Milling Parts Images

BASIC MECHANICAL ENGINEERING

· Mechanical Engineering Dept. 52 Roller Bearings Roller bearings have higher load capacity than ball bearings, load is transmitted through line contact instead of point contact. 49. Cylindrical bearing Mechanical Engineering Dept. 53 50. .

Failure of Cutting Tools and Tool Wear

flat parts Figure (e) pocket milling. Surface Contouring Ballnose cutter is fed back and forth across the work along a curvilinear path at close intervals to create a three dimensional surface form Figure (f) surface contouring. Figure (a) horizontal kneeandcolumn milling machine. Figure (b) vertical kneeandcolumn milling machine . Shaping and Planing Similar operations Both use a single ...

5. DIMENSIONS, TOLERANCES AND SURFACE

• Milling ± • Turning ± Abrasive processes • Grinding ± • Lapping ± Surface finish, roughness Casting • Die Casting Good 12µm • Investment Good • Sand Casting Poor 1225 Metal forming • Cold rolling Good 13 • Hot rolling Poor 1225 Machining • Boring Good • Drilling Medium

Horizontal Milling, Vertical Milling

· A milling machine is basically used for shaping, routing, boring, and drilling metals and other solid materials. Generally there are two egories of the milling machine which include the vertical type and the horizontal type. In order to optimize the capacity of the milling machine, it is essential to identify the appropriate milling machine type for specific tasks.

Manufacturing Cost Estimation

CustomPartNet is a free resource for engineers and manufacturers that facilitates product design and cost estimation. Learn about the process cycle and design for manufacturing (DFM) guidelines for a wide range of manufacturing processes, including injection molding, metal casting, machining (milling and turning), and rapid prototyping. Get fast and accurate cost estimates by using our ...

68 Machinist projects ideas | metal working, metal working ...

Apr 22, 2016 Explore Denis Spiratos's board "Machinist projects" on Pinterest. See more ideas about metal working, metal working tools, metal lathe.

CNC Milling Machine Spindle [Complete DIY Guide ...

[ CNC Milling Machine Parts Home] The cnc spindle is the heart of any mill. It consists of a rotating assembly with a taper where tool holders may be installed. A cnc spindle motor with optional transmission of some kind rotates the cnc spindle. The transmission matches the highest power rpm range of the cnc spindle motor to the spindle rpms that are ideal for the particular ...

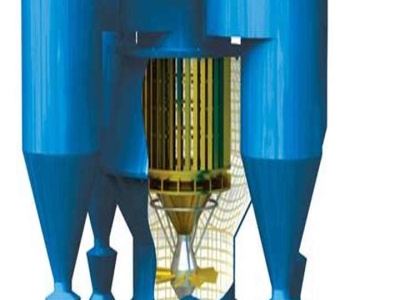

Colloid Mill: Operating Principles, components, Uses ...

· Colloid mill is a machine used in the disintegration of solid particles or droplet size of a liquid present in suspension or emulsion. The machine consists of an inlet (which is subjected to a tremendous shearing action that effects a time dispersion of uniform size) and an outlet. Colloid mill works on the rotorstator principle. The equipment breaks down materials by forming dispersion of ...

CNC Machine Kits

Click Here to See it in Action! Large Format 4'x8' greenBull 4X CNC Machine Kit, a stronger alternative to the blackFoot CNC machine Complete Kit. This CNC machine has a routing area 4 ft wide and as long as you want (standard length is 8 ft). Extra Large Format 5'x10' greenBull 5X CNC Machine Kit .

RICE MILLING

) Traditional Method:Before the advent of mechanical milling, handpounding traditional method of rice milling was in practice. In fact, handpounding rice has got more nutritive value as compared to machine milling rice. In handpounding, a variety of implements is used such as :Mortor and Pestle, Hand Stone (Chakki)etc ) Mechanical Method:With the introduction of mechanized mills, hand ...

Best mechanical engineering design software | Ultimate ...

This is a good and complete software solution to do some rapid prototyping for your mechanical parts, but also to produce your enduse products. Mathematica. Mathematica is a technical computing system that could totally allow you to create solid parts for your future 3D printed mechanical parts. It is offering advanced features, such as 2D and 3D data visualization, function and geo ...

Engineering Guidelines for Selecting Mechanical Design ...

· Part of the reason it's hard to find advice is that the answer is nuanced and varies with your specific situation. But I think the following things are key to understanding tolerances. #1. YOU have to figure out for your specific design how far off the dimensions can be from perfect and still end up with a functional part/assembly.

Construction of DC Motor (Parts Images) | Electrical4U

· Construction of DC Motor (Parts Images) January 24, 2021 March 20, 2013 by Electrical4U A DC motor is a device that converts direct current electrical energy to mechanical energy (learn about a DC motor's working principle ).

CNCGUNSMITHING

· Click here or on the image to the left to get more details. Below the trigger slot adapter plate image you will see the milling adapter kit to help you remove the material from the fire control pocket in AR style lowers. You no longer need a big milling machine to remove the material from the fire control pocket. It can all be done right on your drill press. Visit the ...

How to use a Milling Machine

Milling helical parts requires the use of special formed milling cutters and doubleangle milling cutters. The calculations and formulas necessary to compute proper worktable angles, gear adjustments, and cutter angles and positions for helical milling are beyond the scope of this manual. GEAR CUTTING . Gear teeth are cut on the milling machine using formed milling cutters called involute gear ...

Types of Milling Cutters Used in Machining Process

Milling is a cutting process where we use a cutter to remove the material from the surface of a metal or work piece. This cutter which we use has multiple rotating cutting surfaces. Milling cutters play an important role in the milling process and they are used in several milling machines. Milling cutters are of many sizes and shapes.

Milling Machine Terminology – Sherline Products

Mill Vise—A small vise that is clamped to the mill table and holds parts for milling. It is different from the more common drill press vise in that it tightens with a pulldown function that helps hold the part down as well as in to counter the forces of milling. It is also accurately machined so it can be aligned in the machine for accurate cuts. Holddown Set—A series of adjustable ...

Mechanical Projects – 1000 Projects

· Mechanical Project Documentation on Forged Steel and Powder Metal Connecting Rods MTech Mechanical Project Report on Failure Analysis of Shell and Tube Heat Exchanger Fabriion Of Vertical AXIS Wind Turbine Horizontal Axis Wind Mill Manufacturing Of PVC Pipe Bachelor Of Technology Mechanical Engineering Project

Homepage

Since 1982 HW Machine Repair Rebuilding has been providing machinery sales, repairs, rebuilds and parts for the metalworking industry. If you are looking for parts for your Bridgeport Series I Milling Machine you can purchase them directly from our web site. Whether you need parts for the basic machine, step pulley top housing, leadscrew assembly, quill housing assembly, variable speed ...

What is a Drilling Machine

· Here are some different types of drilling machines with their construction, characteristics, and uses. 1. Portable drilling machine (Hand drilling machine): generally small in size and contains a universal motor, used for drilling holes on the rocks or any rigid surface, suitable for any loion. The piece to be drilled is held in a vice.

Types of Lathe Machine

What is Milling Machine – Operation, Parts and Types. Water Jet Machining – Working Principle, Advantages and Disadvantages with Appliion ; Difference Between NC and CNC Machine; Types of Lathe Machine Lathe/ Wood Lathe. Image source. Remember the Baseball bat, wooden bowl? These are some of the products which can be easily made on wooden lathes or speed lathes. As .

Introduction to Machining: Milling Machine

Vertical Milling Machine is Most Common • Milling machines are very versatile. They are usually used to machine flat surfaces, but can also produce irregular surfaces. They can also be used to drill, bore, cut gears, and produce slots. • The type of milling machine most commonly found in student shops is a vertical spindle machine with a swiveling head. Although there are several other ...

IDENTIFYING MACHINE PARTS, CONTROLS, AND THEIR .

IDENTIFYING MACHINE PARTS, CONTROLS, AND THEIR FUNCTIONS. (Figure J3). components of this machine tool. A dovetail slide is. guide for the knee. A similar slide is machined on the top of. the column to provide a guide for the ram. The top column. wide .

Manufacturing Processes and Materials: Exercises

processes include turning, milling, drilling, grinding etc. mechanical operations. Back in the 1940s the needs of the defense industry, aviation and space industry, electronics and other industries necessitated machining techniques to be adopted for processing thin, fragile or special and very thin products that could not be manufactured using the conventional processes or this would have been ...

Latest Posts

- شنغهاي جسر كسارة مخروط

- كسارة فكية محترفة صنع في العالم

- رسومات cad كسارة الفك

- كسارة هاركا الفك 250 × 400

- الصخور كسارة للبيع في الولايات المتحدة الأمريكية

- تجربة طحن الفحم

- مصنعو مصانع معالجة خام الحديد الكامل في أوروبا

- نوع كسارة متنقلة للفحم

- نظام تكسير 200 طن في الساعة في السعودية

- تستخدم كسارة الحجر من اليابان جيئة وذهابا

- مصنعي ألواح الجبس الجزائر

- معدات طاحونة السودان

- السيليكا مصنع غسل الرمال في مصر

- الفلسبار طحن مصنع في مصر

- العراق مصنع سحق

- Manufacturers Sand Crusher Manufacturers Sand Crushers

- Tpd Cement Grinding Ball Mill

- Vibrating Screen Tensioning

- Milling Machine And Asphalt Pdf

- Irock Crusher Llc Cleveland Oh

- Milestone Program For Aggregates Crushing Plant

- Jaw Cristobalite Crusher Welcomed

- Projectripports Of Crusher Units In Kerala

- Crusher Dealers Andhra Pradesh

- Hartl Crushtek Crusher

- Vibrator Screening Machine For Sand And Gravel

- Ball Mill China Zme Quarry Crusher Price

- Dubai Stone Crusher Sale Price

- Mining Stone Crusher Sales

- Gold E Traction Flowchart