Mill Cement Industry 17781

Cement manufacturing

The cement mill grinds the clinker to a fine powder. A small amount of gypsum a form of calcium sulfate is normally ground up with the clinker. The gypsum controls the setting properties of the cement when water is added. The basic components of the cement production process. Get a Better Understanding of Cement . Articles like this one can provide a lot of useful material. However ...

Integrated performance enhancement in the cement industry

· Even in the case of the cement industry in the MENA region, significant gains from optimising distribution and product mix strategy have been demonstrated. Nonconventional areas . The improvement initiatives in the MENA region's cement industry have largely been restricted to conventional areas for cost reduction. Areas that have so far not been fully optimised include: .

Raw Mill In Cement Plant,Cement Making Plant

In industrial countries, 80% or more of cement is delivered in bulk. Our raw mill has been widely used in the cement making plant. In a large number of customer feedback, we received a lot of enthusiasm and positive reaction. They speak very highly of our machines. According to a lot of customers' response, this plant generally have the following four advantages. Large appliion range ...

Cement mill

ball mill Ф1830×6400. horizontal for cement. ball mill. Ф1830×6400. Output: 7 t/h 16 t/h. The Ball mill Ф1830×6400 model is manufactured by Shanghai Joyal Machinery Co., and is a grinding plant that has been specifically developed as a component that is ideal for use in secondary grinding after crushing.

cement ball millings

Used Ball Mills, industrial and commercial ball mills including pebble mills, sag mills and more. Know More; asphalt milling portland or . Ball Mill; Raymond Mill; ... a paved road surface of either bituminous asphalt or Portland cement concrete. Asphalt millings may be used as surfacing materials if an ... Know More; 25tph Ball Mill Cost, Grinding Ball Mill For Sale In . Ball mill is ...

CEMENT INDUSTRY

Cement Industry Trends Report Cement Exports by Country Below are the 15 countries that exported the highest dollar value worth of cement during 2016: Table 1 Cement Export by Top fifteen countries in 2016 Countries Value in L'SS % of Total Cement exports 1 China US % 2 Thailand million % 3 United Arab million 6%

Rawmill

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the ...

PPC Cement Manufacturing Process

PPC cement has good compressive strength that can reach 13MPa in 3 days, 22 MPa in 7 days, and 33 MPa in 28 days. The hydration rate and hydration heat of PPC cement is low, which is related to the variety and quantity of mixed materials. PPC cement has a high resistance to sulfate attack in acid water and carbonic acid environment.

Ball Mill Limestoneeuropean Limestone Grinding Mill Company

Ball mill is the key equipment for deep grinding of materials after primary crushing It is widely used in cement, silie products, new building materials, wearresistant materials, fertilizers, ferrous and nonferrous metal mineral processing and glass ceramics industries According to the processing technology, it is divided into two grinding waysthe dry and the wet Besides, wet ball ...

Vertical Roller Mill In Cement Industry

Vertical Roller Mill In Cement Industry. Vertical roller mills, especially those common for grinding of cement raw materials, typically employ a hydraulicpneumatic system to apply a grinding force to the material operation, these systems will contain pressurized hydraulic fluid in an isolated branch of the circuit consisting principally of cylinders and accumulators.

VERTICAL CEMENT MILL

Process introduction The GRMK vertical cement mill of CHAENG adopts a new generation of cement grinding technology, which integrates grinding, drying and powder selecting functions. It can save 30% of power per ton compared with traditional ball mill. At the same time, it has many advantages, such as less auxiliary equipment, multiple functions, small occupied area and little dust pollution.

Vertical Raw Mill Cement Industry Animation

Cement Industry Raw Mill Vibration Monitoring Amp. The separator of Raw mill is adjacent Hello Experts I request you to please provide me your valuable suggestions regarding the following problems 1) Our Raw Mill creates too much vibration and mostly it is coming from the grinding rollers running inside when they come in contact with the rotating raw mill cement industry pdf ...

Digitalisation in the cement production process | FLSmidth

The cement production industry is realising the potential of connectivitybased technologies, often referred to as Internet of Things (IoT) technologies. We see it as the convergence of information and operations technology, providing valuable data about plant equipment. Understanding the advanced sensing and data analytics allows cement plant managers to make better decisions about the ...

Analysis of Raw Mill Machines Maintenance in Cement Industry

· Analysis of Raw Mill Machines Maintenance in Cement Industry. To cite this article: R M Sari et al 2020 IOP Conf. Ser.: Mater. Sci. Eng. 851 012051. View the article online for updates and ...

raymond vertical for cement processing

Cement mill The output of cement mill is 21155 th and the specific surface area of cement is cm g Cement mill has the advantages of small occupied area stable running convenient operation and other advantages so as to achieve the high yield and high fineness which has provided a strong guarantee for the production of high quality cement . raymond vertical for cement processing ...

Raw Mill – Kiln Appliion in Cement Industry | Thermax

Raw Mill – Kiln Appliion in Cement Industry. THE CUSTOMER PROFILE. M/s. Chettinad Cement Corporation Limited (CCCL), An Indian Rs Billion business group is into Manufacturing (Cement, Silica, Quartz, Grits) Services (Construction, Transports, Ship Management, Clearing Forwarding), is one of the major cement manufacturers in Southern India with total cement production capacity of 3 ...

Cement and its effect to the environment: A case study in ...

The cement industry recognizes its responsibility to manage the environmental impact, associated with the manufacturing of its product. Mainly, there are two types of cement production process; such as wet process and dry process. The preparation of cement includes mining, crushing, and grinding of raw materials, calcining the materials in 1408. rotary kiln, cooling, resultant clinker, mixing ...

Cement Industry News Updates

· Trading 29 October 2021 Bangladesh's cement industry export revenue dips in 03MF22 Bangladesh's cement industry has earned export revenue of US in the first quarter of FY22 (July – Sept ), compared to US in the yearago period, a fall of per cent YoY.

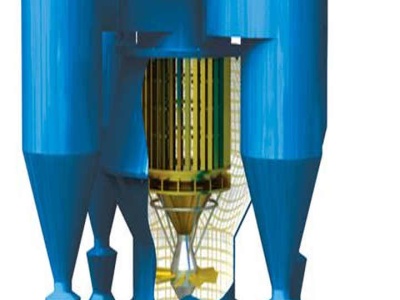

Preheater In Cement Plant

Cyclone preheater, also known as suspension preheater, is the main cement equipment commonly used in the new dry process cement production line. It is the main gassolid reaction unit of the cement raw meal predecomposition system, which makes full use of the hightemperature exhaust gas discharged from the kiln tail and the hightemperature flue gas generated by the combustion at the .

Vertical Roller Mill Parts

Ecorporates GmbH is leading and experienced supplier of highquality wear resistant parts for Vertical Roller Mills in cement, mining and power industry worldwide. Based in Germany, our company has experience of many years for providing products and solutions in High Chromium Cast Iron and Composite Metal Ceramic for achieving better lifetime. Continuous research and development have .

Major Industries Of Madhya Pradesh Part 1

· In this phase limited industries were developed in Madhya Pradesh, specially related to natural resources forest, cement and cotton industries were Burhanpur cotton mill 190607, Malwa cotton mill – Indore 1907 08, Associate Cement factory(ACC) Katni, Banmore factory – Morena, Kaimur Factory, Bhopal sugar mills – Sehore 1939. After Independence the main cities of .

Latest Posts

- أرض للحجر محطم

- الفك كسارة المحرك

- كسارة الخرسانة أرمينيا

- موردي كسارات الركام في الجزائر

- آلة تكسير الكوارتز لمصنع المعالجة

- معدات تكسير حجارة المرارة

- السعودي محطم الجهاز المحمول

- القليل الفك محطة كسارة المحمول

- أبرز مصنعي كسارات الكوارتز في مصر

- التكنولوجيا المتقدمة كسارة الصخور الهيدروليكية كسارة مخروط

- محجر cgm الطاحن تصميم كسارة لفة واحدة

- الأولية كسارة الفك للبيع المملكة العربية السعودية

- كسارة التعدين ومعدات الطحن

- تصميم آلة كسارة الحجر الأسطوانة العمودية

- الغرض من كسارة الحصى

- Coal Import And Supply Services Guyana From Indonesia Oreplus

- Jaw Crusher For Sale In Malaysia Stone Jaw Crushing Plant

- Small Ball Mill Manufacturer

- How Many Cement Mill Ball Charge

- Construction Vibratory Screening Equipments For Sale

- Adverts For Grinding Mills

- 1500 Ton Hr Li Ne Crusher

- Dry Grinding For Ceramic Qatar

- Second Hand Ball Mill Mining Equipment South Africa

- Hot Selling Limestone Raymond Mill

- Ethiopia Mining Plant Manufacturer

- Gyratory Crushers For Sale

- Crushing Manufactures In Austria

- Damage Happen In Ball Mill Crusher

- 150 180 Tph Tanaman Bijih Emas Crusher