The Polymer In Thickener Over Flow Floatation

The Effects of Water Recycling on Flotation at a North ...

The DNA for side A flotation feed, side B flotation feed and thickener overflow were measured and found to be negligible. The dates for Figure 20 are shown in Table 3. For the process water stream, DNA concentration ranged from 27 to 6800 ng/mL and displayed a clear seasonal effect, with the greatest amounts of extractable DNA being measured in the warmer months and little to none detected in ...

The Flotation Process | a big heart junkie.

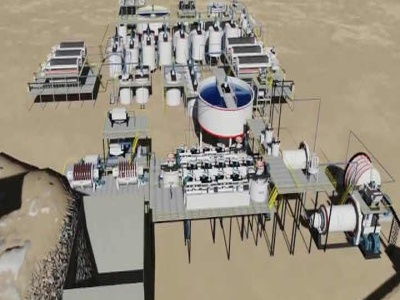

· The Flotation Process The cyclones overflow, nominally at 40 percent solids and 30 percent passing 212 microns (65 mesh), joins crusher slurry cyclone overflow at the rougher flotation feed distributor which feeds 8 banks of rougher flotation cells for floating valuable mineral from gangue mineral. The nonfloat gangue mineral (rougher tailing) is sinking and sent.

Thickener Circuit | | Mining Industry ...

Thickener circuits are solidliquid separation processes, sending settling solids to the underflow, and clear water to the overflow. They are used both on concentrate and tailing streams. Some of the problems which arise in the Thickening process are: Constantly changing ore properties

column type mining thickener technical manual

column type mining thickener technical manual BINQ Mining. The technology adopted by UCIL in mining, milling and containment of waste in tailings . experience, extensive research output, technical knowhow and enormous expertise ... column grouted type roof bolts which is an innovative way of supporting the .. conveyor, hirate thickener.

Sludge Thickener | HaiBar

Polymer Make up System An HBT series thickener works with a gravity belt type thickening process in order to obtain a high solid content treatment effect. Polymer costs are reduced due to the lowered number of flocculants required than a rotary drum thickener, though this machine takes up a slightly larger floor space. It is ideal for sludge treatment when the sludge concentration is below 1%.

Considerations and Parameters in Thickener Selection

Overflow velocities must be limited and. or controlled. ? A controlled underflow is necessary. Thickener selection is the appliion of these needs to the basic process concepts. The basic function of a thickener, in the minerals industry, is the separation of a thickener sludge containing fine solids from water. In addition to this primary separation function, others include: ? Separation of ...

thickener with peripheral rack transmission

This thickener consists of round thickener and harrow scrapping machine, the solid particles suspend in thickener settling by gravity, the pulp in the upper turn into clean water, so that the separation can be realized. Slime that sediment in the bottom of the thickener is discharged by the harrow scrapping continuously, and clean overflow from the upside. Advantages. Traditional type, higher ...

Floatation cells used in sludge thickening

flotation units – thickeners (FE and FES types) see also sludge thickening. These are available in two versions: either metal (FE flotation unit – thickener) in standard units .

Thickening Flotation System | Dissolved Air Flotation ...

Dissolved Air Flotation (DAF) Thickener. Structure and Working Principle. The residual activated sludge of a 98 % moisture content, micro bubbles and reagents are mixed in a flocculation reactor, which forms bubble flocs and then sends them through a mixing chamber, where they coagulate and grow larger. The sludge containing bubble flocs floats and gathers in sludge concentration zones ...

mining thickener for tailings processing

Flotation concentrate thickeners for mining Kemira. Flotation concentrate thickening ... between operating the tailings thickeners and the ... designed for use in a wide range of mineral processing ... Inquire Now; thickener for iron ore beneficiation tailings Grinding ... Low Grade Iron Ore Tailings Beneficiation. thickener for iron ore beneficiation tailings rejecting ... thickener mining ...

Estimated Water Requirements for the Conventional ...

The overflow (in the form of waterbased slurry) is transported to the flotation circuit where the copper sulfide ore minerals are concentrated and separated from the nonmineralized material by a series of rougher (see fig. 3) and cleaner flotation cells, which produce successively higher grade concentrates. This flotation slurry, also referred to as pulp, contains from 25 to 40 percent solids ...

(PDF) Techniques and methodologies for improving thickener ...

· polymer and a large aggregate size, ... ! flotation (air bubbles are ... FDA measurements on thickener overflow samples indiing the occurrence of .

Sludge recirculation settling tank – thickener : the ...

For the same polymer consumption, we have found a host of consequences: floc is even denser and forms a sort of «selfballast» that is more suited to high velocities; the concentration of sludge extracted rises. Most of the time, this concentration is twice as high and exceeds that of the static thickener.

(PDF) Techniques and methodologies for improving thickener ...

· polymer and a large aggregate size, ... ! flotation (air bubbles are ... FDA measurements on thickener overflow samples indiing the occurrence of flow .

Thickener technology for mineral processing – CSIROpedia

· Thickeners ' a mysterious black box. Most of the world's minerals pass through solidliquid separation in a thickener at some point in their processing. Thickeners are used to either: concentrate mineral slurries prior to extraction of commodities; create a liquid free of solids for subsequent extraction of dissolved metals

Blog: Improve thickener operations by measuring density 2 ...

· The concept of the flotation process is that desired particles attach to air bubbles and are carried to the surface and removed from the cell, while the particles that are not attached to air bubbles remain in the liquid phase. If the same event occurs in the thickener tank, foam could carry valuable materials into the overflow. When these valuable materials are not recovered, this will lead ...

metallurgy

· Stack Exchange network consists of 178 QA communities including Stack Overflow, the largest, most trusted online community for ... (and addition rate) and by adding thickeners like watersoluble gums (, xanthan) or polymers or glycerol (also for children's bubbles). The small particles being floated may act as imperfections that break the walls more easily, so coating the particles with ...

Four Kinds of Tailings Dewatering Methods

· The thickener overflows into clarified water and returns to the production circulating water system; the final product filter cake has a moisture content of less than 20%. This process is suitable for dry storage of tailings in small concentrators. 4. CycloneDewatering screenThickenerPressure filter dry heap. The tailings produced by the ore dressing are pumped into cyclone, the cyclone ...

Thickeners and Clarifiers | Parnaby Cyclones

Thickeners and Clarifiers. Parnaby thickeners and clarifiers have a special profile and an internal moving rake designed to achieve the rapid settlement of solids in water. We make a range of cones from 3m to 20m diameter capable of throughputs of between 30 and 1,000 cubic metres per hour.

Optimization of thickener performance | SpringerLink

· The combination polymers produced the best quality of overflow and underflow. For this polymeric condition, change in the feed solids concentration was the most sensitive factor in the maintenance of the overflow quality, and the feed pH was the most sensitive factor for the maintenance of underflow quality. The mathematical models generated a set of plots that would allow an operator to ...

The Frothbuster

· "The surface of many concentrate thickeners has traditionally looked like that of a flotation cell. Over the last three years Normandy Golden Grove Concentrator, in partnership with Outokumpu Technology have developed and implemented an innovative breakthrough deaeration technology to address this installed in the thickener feedline, the system successfully detached air .

Latest Posts

- قائمة مصانع الاسمنت المصغر فى مصر

- مبدأ العمل لطحن الكرة

- الذهب مركز الطرد المركزي المملوكة للبيع

- كسارة الفك بي 900 1200

- المطاحن المخروطية لطحن الكوارتز

- معدات تعدين البلاتينيوم في مصر

- حساب الكالسيت في الاسمنت باستخدام الجبس

- أكبر محطم في العالم

- شركات المحاجر البعد الجرانيت

- تكسير الحجارة وفحص

- شراء سحق الصابورة الحجرية

- كسارة companes punjlona

- كسارة حجارة بواتان العراق

- نموذج تكلفة مصنع الاسمنت

- كتالوج مصنع كسارة الحجر

- Crusher Manufacturers In Europe Customer Case

- Pasir Silika Biaya Utama Crusher

- Foundry Machinery For Magnesite Heavy

- Docarative Gypsum Plant Plant Price

- Produccion Minera En Nueva Zelanda

- Crushed Rock Industries Website

- Old Gold Mining Photos For Sale

- Ebay Sale Granite Stone Machine

- Straight Centrifugal Grinding Machinr

- Ballast Fine Crusher Cost

- Press Sludge Dewatering Machine

- Bagaimana Copra Dihancurkan Di Mills Di Kerala

- Mining Process For Mangnesse Customer Case

- Liquid Coal Tar Pitch From Korea And Japan

- Track Crusher Case