Cement Plant Grinding Unit Flow Chart

process flow chart cement grinding unit in australia

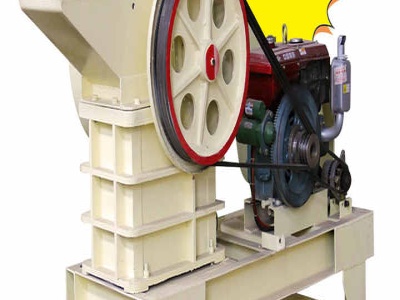

Cement Grinding Plant. Feeding Size: ≤25mm Production Capacity: 200t/d8,000t/d Technological Features: Crushing raw materials, prehomogenizing materials, arranging ingredients, efficient grinding, homogenizing materials, suspending preheater and decomposing furnace, new type cooler, cement dosing and grinding. Details; Cement Mill. Rotation Speed: –5 r/min

cement grinding unit process flow diagram

flow chart of lime stone grinding plant. Wholesale Various High Quality Ball Mill Flow Chart Products from G cement clinker grinding manufacturing process flow chart US grinding unit of cement...

cement plant grinding unit flow chart

cement plant grinding unit flow chart. project on fabriion of grinding mill cement plant grinding unit flow chart 12 May starch mills process flow chart Crusher South Nov 20 Karara exploration camp upgrade Fabriion of Karara erection for shut down project Complete cement plant grinding unit machinery design and fabriion accidentLoesche Mills for

Best energy consumption

· Typical cement plant power costs can range from EUR39 to EUR170/MWh. Mill designs. The most important first step in controlling energy consumption is to be aware of the relative importance of the process areas where most energy is consumed. Figure 2 shows a typical breakdown of electrical energy consumption at a cement plant.

Cement Manufacturing Process Flow Chart

Mentioned cement production people will say "two grinding burn",that means cement production process mainly includes three stages: raw meal preparation, clinker burning and cement grinding. The cement manufacturing process flow chart is shown as follows:

Clinkerization

Plant P8: This plant is a grinding unit with a production of Mt. The total electricity consumption is M kW h. Plant P9 : The plant P9 produces Mt of cement (OPC and PPC) with an estimated energy consumption of × 10 6 M kcal.

IELTS Diagram: Model Answer Band Score 9

· The flow chart illustrates the process of making cement, while the other diagram shows how different materials are combined with the product to produce concrete. Overall, cement manufacturing takes four steps, beginning with crushing and ending with cement in bags.

Éric Edet, Product Manager, Fives FCB, France, uses the ...

the grinding plant settings to ensure the final cement production and quality, from the cement composition to the target silo. Autostart. The main steps of the automatic startup sequence (mentioned above) can be described as follows: Start of the hydraulic pressure unit and the lubriion system. Start of the cement transport.

Vertical roller mill for raw Appliion p rocess materials

Fig. Flow chart of roller mill adopting the external circulating system. ... The conventional process gas flow of the mill grinding system generally consists of vertical roller mill with separator, cyclone, ... has been still used many existing cement plant. The improvement of this tube mill grinding .

Cement Manufacturing Procedure Flow Chart

flowchart of wet process cement manufacturing Cement Manufacturing Process Flow Chart Cement manufacturing process is mainly divided into three stages namely raw meal preparation clinker burning and cement grinding Generally speaking the cement industry production is Portland cement Portland cement is a kind of delie usually gray powder which consists of calcium What is the manufacturing ...

Manufacturing Of Cement By Dry And Wet Process

· Cement Manufacturing Process Flow Chart. (i) Drying Zones: In the wet process, the drying zone is comparatively larger than the dry process. It is because the raw material in slurry form is directly fed into the kiln which has more amount of water. As shown in .

Gypsum Manufacturing

A flow diagram for a typical gypsum process producing both crude and finished gypsum products is shown in Figure In this process gypsum is crushed, dried, ground, and calcined. Not all of the operations shown in Figure are performed at all gypsum plants. Some plants

Manufacturing of Portland Cement – Process and Materials ...

· The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 ⁰C. During this process, these materials partially fuse to form nodular shaped clinker by broking of chemical .

cement grinding plant units of flow charts

cement grinding plant units of flow charts. Cement mill A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into, This helps keep the mill cool, and sweeps out evaporated moisture which would otherwise cause hydration and disrupt material flow, For this reason, plants with highly seasonal demand usually have very large clinker stor.

cement grinding plant units of flow charts

process flow chart cement grinding unit. cement grinding plant units of flow charts. Cement Grinding Plant Chart concretedayeu process flow chart cement grinding unit Cement LCI 2006 pdf National Ready Mixed Concrete Association The function unit is a unit mass of portland cement manufactured in the preparation pyroprocessing finish grinding and all .

How does a concrete batch plant work | Operation of ...

· Mixing unit – This is the most critical part and heart of the concrete batch mixing plant. The job of the mixer is to receive all the ingredients and mix them thoroughly for a fixed time. Then it will discharge the contents into a transit mixer or a concrete pump. Air compressor – Air compressor is one of the important components here.

Process Flow Diagrams REFINERY PROCESS

REFINERY— PROCESS FLOW DIAGRAMS 5 Process Flow Diagrams — Refinery Conversion Process — Typical Distillation Unit Process Desciptions One of the other feedstocks to a refinery is hydrogen, which can be used in a hydrotreater, isomerization, FCC, reformer, and a complex, capitalintensive unit.

Air Pollution Control in the Cement Industry

The high efficiency curves on both graphs indie for a 400,000 unit a 300,000 purchase cost and a 600,000 total installed cost. Applied to a cement kiln, such a unit .

Portland Cement Manufacturing

· Classifiion Code (SCC) for portland cement plants with wet process kilns is 305006, and the sixdigit SCC for plants with dry process kilns is 305007. Portland cement accounts for 95 percent of the hydraulic cement production in the United States. The balance of domestic cement production is primarily masonry cement. Both of these

(PDF) Analysis of material flow and consumption in cement ...

· The results show that approximately,, and of materials are required to produce a ton of the product in raw material preparation, clinker production, and cement grinding stages ...

Supply Chain Management in the Cement Industry

cement supply chain. First, GrindtoOrder where cement is kept in clicker (intermediate product of the cement manufacturing process) and then grinded as orders appear. Second, PacktoOrder, where cement is kept in bulk and then packed as orders appear. Further research should be made to confirm the feasibility of these alternatives.

Flow Chart of Wet Processing Process

· Flow Chart of Wet Processing Process (Cotton Goods) This is the most widely used wet processing flowchart in the contemporary textile industry. But sometimes on some factories the scouring and bleaching are done simultaneously. The main objective of wet processing in cotton is to take a gray cloth and make it a finished fabric.

flow chart grinding cement plant

flow chart grinding cement plant. cement plant grinding unit flow chart Flow Chart Essential Requirement for set up of Clinker Grinding Unit Main Factory Shed Include Raw Material GodownStore Elec detailed energy audit and conservation in a cement plant IRJET Abstract A Cement plant is an energy intensive industry both in terms of thermal chart ...

Latest Posts

- كسارات مخروطية التعدين المستخدمة

- الصابورة كسارات مستعملة للبيع

- بوابة غسل الرمال الذهبية

- الشركة المصنعة لآلات المحاجر sbm

- mesin pembuat طحن الكرة

- كسارات للبيع في نيوزيلندا

- الزنك الكرة خام مطحنة

- كسارة صخور مستعملة للبيع في السعودية

- الآلات المستخدمة في تعدين البرازيل

- كسارة الحجر الصين 300tons ساعة

- معدات تكسير معدات الأشغال العامة

- آلات كسارة الزجاج بسعر المملكة العربية السعودية

- مصنع محطم للحجر في أعلى بالقرب من باريلي

- harga air raksa cuci emas

- ورقة تدفق وحدة طحن الأسمنت

- I Found A Gold Ball In Subway Surfers

- Kecil Micronizer Ball Mill Singapore

- Rock And Sand Roller Mills

- Concrete Block Sizes And Weights

- Mobile Crusher Indonesia

- Portable Brick Crusher In West Bengal

- Solid Carbide Bar For Vsi Crusher

- Coal Mining Togo 2020 Ppt

- Advanced Durable Efficient Hydraulic Cone Crusher Machine

- Rare Earth Mining In Malaysia

- Grinding China Dubai

- Vibrating Screen Machine Cost

- Gypsum Powder Manufacturing Process �Ccrusher Mill China

- Crusher Dasar Reproduksi Terna

- Alumina Grinding China