Iron Ore Concentrate Process Plant

iron ore crushing mining process concentrates

List Of Iron Ore Concentrate Plant, process crusher, mining get price. Iron ore Wikipedia OverviewExtractionSourcesMine tailingsProduction and consumptionAbundance by countrySmeltingSee also. Lowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the ...

Metal ore mining in Europe

The ore body in Kiruna is a massive block of highgrade magnetite ore, 4 km long, 80 m wide and extending over a depth of 2 km. Fig. 5 shows the proven existing reserves of iron ore at the 4 LKAB mines, as well as the iron grades of the ores in the reserves. The resources [3] are actually much larger, so that ore mining will be possible for several decades in Sweden if appropriate economic ...

Mining | Sectors

Filtration plant for iron concentrate . A filtration plant for iron concentrate for Shri Bajrang Power and Ispat Ltd, a leading Indian producer of iron ore, steel and steel products. The plant scope includes a filter press and a slurry pump and can produce 95 t/h. Industry: Mining. View project

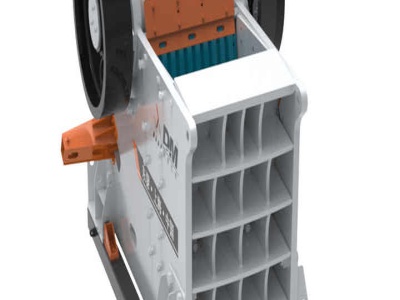

The Latest Developments in Iron Ore Processing

–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones – diameter –Operating capacity of 600800t/h –Efficient separation at SG's as high as /cm3 Dense Media Separation on Iron Ore •

Direct reduced iron

Process. Direct reduction processes can be divided roughly into two egories: gasbased, and coalbased. In both cases, the objective of the process is to remove the oxygen contained in various forms of iron ore (sized ore, concentrates, pellets, mill scale, furnace dust, etc.), in order to convert the ore to metallic iron, without melting it (below 1,200 °C (2,190 °F)).

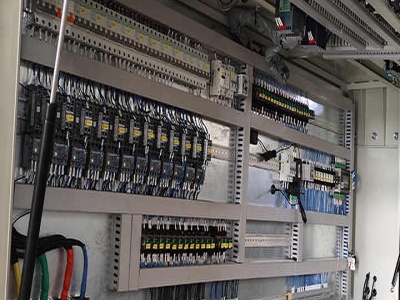

Iron Ore Concentrator | MultiDiscipline EPCM Company

Iron Ore Concentrator. USA << Back to Mining Minerals Projects. Project Highlights. Addition of a concentrator plant to an existing ROM ore loadout system; Fastpaced project complete in 13 months from testing to startup; In addition to traditional EPCM services, SE acted as agent for the Client for all purchasing and contracting ; Services. Detailed Engineering – Process, piping ...

concentrate iron ore process

Iron Ore Concentrate Process Tailings Iron Ore Concentrate Process Tailings After the tailings are processed into iron ore concentrate and organic fertilizer the remaining material will be discharged back into the tailing basins Since most of the metallic elements will have been removed from the material the material will possess the characteristics needed to promote plant growth . read more ...

Basic characteristics of Australian iron ore concentrate ...

iron ore concentrate in the sintering process, four tests [3] including assimilability, liquid fluidity, bonding phase strength, and crystal strength [8] were carried out using the microsinter equipment. The Australian iron ore concentrate was dried at 105°C for 3 h and ground to a particle size less than 147 μm. In the measurement of assimilability, the iron ore was compacted into a ...

Iron Ore Facilities :: ClevelandCliffs Inc. (CLF)

At the plant, two additional stages of crushing occur before the ore is sent to the concentrator. The concentrator utilizes rod mills and magnetic separation to produce a magnetite concentrate, which is delivered to the pellet plant loed onsite. The plant has a ship loading port loed on Lake Superior.

:: bpi :: | Middle East Mines and Mineral Industries ...

· iron ore concentrate plant No. 1 with an annual capacity of 2 million tons (September 2012) iron ore concentrate plant No. 2 with an annual capacity of 2 million tons (September 2015) direct reduction plant with an annual capacity of 1 million tons of sponge iron (February 2015) coal processing plant with an annual capacity of 550 thousand tons .

Marampa Mines

Our project aims to build a resilient, and longlife iron ore mine in Sierra Leone, by significantly expanding iron ore operations and integrating mining, processing, and rail and port logistics. A specially designed processing plant takes iron ore of around 32% Fe content that is mined from the ground and upgrades the resource to achieve >65% Fe content, an exceptionally highquality iron ore ...

Iron Ore Concentrate

Iron Ore Concentrate Edit Edit source History Talk (0) Iron Ore Concentrate Item information Item Type {{{type}}} Stack Size. 100 Input Output Crafting Stations Iron Ore x3. Iron Ore Concentrate x1. Sand x2. Mineral Processing Plant. Categories Categories; Add egory; Cancel Save. Community content is available under CC BYNCSA 3 .0 unless ...

SAFETY GUIDELINES FOR IRON STEEL SECTOR MINISTRY OF ...

PROCESS: Pellet Plant produces Pellets using Iron ore and additives such as limestone, bentonite, coke, anthracite coal, quartzite which are passed through balling disc/drum and the green pellets so formed are passed through a furnace either straight grate or rotary kiln to produce High Grade Pellet which are used in Steel making in Blast furnace or Direct reduction plants for steel making ...

Iron Ore Concentrates Process

Iron Ore Processing For The Blast Furnace. blast furnace process The iron ore concentrate is now mixed and ready for the pelletizing process Pelletizing A pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets in much the same manner that one rolls a snowball to make a pellet about the size of a marble between 14quot and 12quot.

How to Calculate Grade and Recovery with ...

· The ore is an iron oxide with a silie gangue. After 1 hour, we take samples from the concentrate and tailings. Chemical assays showed that the concentrate grade 75% iron and 2% in the tails. Suppose we have throughputs of 100 kg, 300 kg per hour for concentrate and tails, respectively. If the run of mine grade 20% iron, then in one hour, we ...

Agbaja Iron Ore Project, Kogi

Kogi Iron, an Australian company, is developing the project through its Nigerian subsidiary KCM Mining. The project includes the development of an iron ore mining and processing operation capable of producing five million tonnes (Mt) of upgraded iron ore concentrate per annum. The mine life is estimated to be 21 years.

Iron Ore Concentrate Process

Iron Ore Concentrate Process [randpic] iron ore concentrate process Xinhai The main iron mineral contained in magnetite ore is ferroferric oxide (Fe3O4). Magnetite contains about 85% of iron ore. The hardness of the ore is between and, and the specific gravity is

Namvaran

Choghart Iron Ore Concentrate Plant, ChoghartIran EPCF Services for a 2 MTPA of Iron Ore concentrate using Direct Reduction process (DR), 2013 Client: Iran Central Iron Ore Company (ICIOC)

Iron Ore Processing Plants

Iron Ore. Efficiently remove silica and alumina contamination to increase efficiencies in steel production. Our iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production process.

process of upgrading iron ore concentrates

Ore Processing Plant. Ore processing plant means that extracts and purifies some elements in the raw ore through a series of complex ore beneficiation flow and professional beneficiation equipment. The refined concentrate powder is mainly used in metallurgy and industry base. View Details

JINDAL SAW LTD.

Jindal SAW Ltd. with their innovative ideas and international exposures is upgrading iron ore (ROM) from about 28% Fe to concentrate of 65% Fe by way of magnetic separation and other separation methods as the Ore is mostly magnetite along with banded magnetite quartzite. The magnetite concentrate thus produced is being used for manufacturing of ...

Gold Processing,Extraction,Smelting Plant Design ...

Gold ore. Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

Latest Posts

- فهم تخطيط مصنع الاسمنت

- تعدين الذهب المحطم

- كسارة الحجر مورد قطع غيار على الحدود نيبال

- خطة عمل شركة تعدين الفحم الصغيرة في ط

- أنواع معدات تعدين الفحم

- تستخدم الكسارات المتنقلة الزاحف

- تستخدم الكسارات بيع تنزانيا

- م نبات الرمل sbm

- تعويم اليورانيوم من خامات النحاس

- الذهب المصنع التعدين تخطيط

- المواد الملكية مطحنة الكرة ليتم التعامل معها

- تكسير وغربلة آلات الركام

- خام الذهب المصنع وحدة غسيل المملكة العربية السعودية

- مصر مصر مجففات الرمل

- كسارة الحيوانات الأليفة الأسعار في عمان

- Shanghai Broken Factory Double Roll Crusher

- Turner Machine Shop Inc In Fort Pierce Fl Superpages

- Vsi Sand Machine Flow Chart

- Aluminum Sulfate Washing Equipment

- Bens Quarry Llc Fax

- Truck Sleeper Power Supply

- Cost Saving Gold Mining Queensland Washing Equipment

- Quartz Stone Machine Manufacturing Guatemala

- Carpet Manufacturer Machinary In The Republic Of Congo

- Mesin Crusher Besi

- Barite Grinding Plant Sale China

- Crusher Walnut Line

- Mobile Life Screening Health Screening Services

- Iron O Ide Yellow Ore Powder Machine

- Free Project Report Dal Mill Download