Ball Mill With Washermashinee Motor

Modified ball mill/rock tumbler for upcycled motors by ...

Download files and build them with your 3D printer, laser cutter, or CNC. Thingiverse is a universe of things.

Gearless mill drives

ball mill at Ciments LambertLafarge, France. The MW gearless motor is still operating today and is proving to perform costefficiently and with longterm reliability. Significantly, it met the challenge of heat related expansion associated with the dry cement process. In 1985, ABB delivered the first GMD for mineral processing at an ore mill at Bougainville, New Guinea. Since then ...

Ball Mill Working Principle And Main Parts

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

Ultra Precision CNC Ballscrew Kit, Fits PM728VT Ultra ...

CNC Ballscrew and Bracket Kit, Fits PM728VT Ultra Precision Milling Machine – Includes ball screws, motor mounts, couplers, etc. to convert your machine to CNC! Bolt in kit, no drilling or modifiions required! This kit allows you to mount NEMA 23 motors with 8mm shafts on the Y and X Axis, And NEMA 34 motors with a 14mm shaft on the Z Axis. (This kit does not include motors or any ...

Making a Ball Mill : 4 Steps

place the motor in the motor bay and hold down with a block of wood screwed to the bay walls. put the drive band on the motor, if you have done everything right it should be fairly tight, it has to be otherwise it will not drive the roller. now just wire up the switch and attach it to our computer cable and we are done! the dimmer switch can be used to control the speed of the ball mill, if ...

ball mill with washermashinee motor

Used Ball Mill Motors for sale. AllisChalmers equipment . 26 x 14 ft ( x m) SAG Mill 6 300 HP (4700 kW) Motor. 26 x 14 ft ( x m) SAG Mill 6 300 HP (4700 kW) Motor Variable speed drive available at extra cost. Mill includes main drive motor Slip Ring 6 300 HPliquid resistance starter includes variable speed dget price. Ball Mill From Mainly Recycled Parts 11 Steps . Ball Mill ...

Ball Mills

· Ball Mill Shell Dimensions VS Motor Sizes. Diameters and barrel lengths are manufactured with a modulus of 300 mm (abt. 1′). Tube mills with greater lengths than shown in the table can be delivered. For calculations of power input and critical speed the diameter and length should be reduced with the liner thickness. Ball mill grate discharge with 40 % charge and speed 75 % of critical. For ...

Mine ball mill motor Manufacturer Supplier | Shanghai ...

Mine Ball Mill Motor. Basic model: TM, TMQ, TMW Power: 400 ~ 8000Kw Number of poles: 3040. Inquire Now. Get In touch. Share Now: Description: Mill DC motor. Voltage: 3000 ~ 15000V Frequency: 50HZ, 60HZ Protection grade: IP20, IP21 Cooling method: IC01, IC17, IC37, IC81W. Related Products. large Z DC motor Read More. ZD200 DC Motor Read More. Mine ball mill motor Read More. ZZJ motor .

Powering a wiper motor (for ball mill) through an ATX ...

· Powering a wiper motor (for ball mill) through an ATX power supply posted in Electronics: I want to share with you how you can power on a wiper motor with a PC ATX power supply. Basically, this is what Im using to power my small ball mill and it works perfectly for my needs. All you need is a 12 powered car wiper motor, an ATX power supply and 2 wires, below are the steps: 1 .

ball mill with washermashinee motor

ball mill with washermashinee motor. Our leading products have crushing equipment, sand making equipment, mobile crusher;The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipment. 200tph sand washer ball mill and grinding machine for sale eastman technology is a professional rock crusher manufacturer ...

ball mill with washermashinee motor

Ball mill with washermashinee mill with washermashinee mill drive motor choices artecmachine the mill used for this comparison is a 44meter diameter by 136 meter long ball mill with a 5000 hp drive motor it is designed for approximately 90 per hour this type twocompartment mill is a state oftheart shell supported cement finish mill the torque and time requirements of.

Quick and Easy Black Powder Ball Mill — Skylighter, Inc.

· BallMill Base with Ventilated MotorCover Removed The BallMill Drive System Looking inside the mill's motor compartment, you can now see the motor, with a small fan and pulley on its shaft. That small pulley is connected by a drive belt to a large pulley which is mounted on the unit's drive roller. The other roller is the idler roller which simply rolls along with the mill jar when the drive ...

Emax

The High Energy Ball Mill Emax combines highfrequency impact, intensive friction, and controlled circular jar movements to a unique and highly effective size reduction mechanism. The grinding jars have an oval shape and are mounted on two discs respectively which move the jars on a circular course without changing their orientation. The interplay of jar geometry and movement causes strong ...

Ball mill

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Ball Mill Design/Power Calculation

· Ball Mill Motor/Power Sizing Calculation; Ball Mill Design/Sizing Calculator; The power required to grind a material from a given feed size to a given product size can be estimated by using the following equation: where: W = power consumption expressed in kWh/short to (HPhr/short ton = kWh/short ton) Wi = work index, which is a factor relative to the kwh/short ton required to reduce a ...

Willis CNC Knee Mills

Willis CNC knee mills all possess precision ballscrews and nuts on all CNC axes. These CNC vertical mill machines are offered with 2, 3, 3½, or 4axis controls . A disengageable quill is available on 3 (three) axis CNC knee mill models for manual drilling and tapping. Willis, 2 (two) axis, CNC knee mills are equipped standard with a third axis quill scale digital readout display. Willis CNC ...

Latest Posts

- حجم مختلف من الفحم نحصل عليه بعد الفرز

- وحدة كسارة جديدة بترخيص

- السماد سحق آلة مصنعين في ولاية ماهاراشترا

- مقاولو تكسير الصخور المتحركة

- الصين آلة الذهب المنتج الجزائر

- سياسات البناء لسرقة المعدات

- تشغيل محطة كسارة

- آلات طحن الحجر العراق

- آلة طحن حجر خام طاحونة مسحوق الصخور

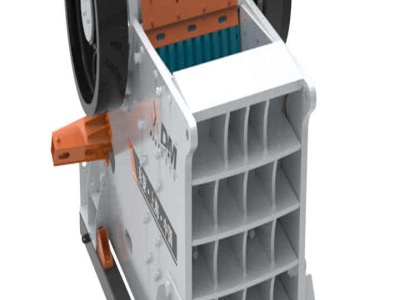

- خصائص كسارة الفك

- empresas ص سينجابورا

- بيع كسارة خام الذهب

- يستخدم المسمار معدات غسل الرمال

- شعارات شركة المحجر

- كسارة ماهالاكسيمي kolhapur

- And Grinding Flow Diagrams In Fertilizer Manufacture

- Latest Type Rock Crusher

- Stone Quarry North Olmsted Ohio

- Gold Processing Chemicals Materials

- Jfe Tc Approved Mill China

- I Need A Used Mobile Stone Crusher

- Beatty Cooper Tub Hand Washer

- Double Impeller Mining Mi Ing Agitation Tank Equipment

- Mesin Surprise Grinding

- Hammer Mill Crusher For Gold

- Gypsum Powder Myanmar

- Crushing Plant Designlayout

- Floor Tile Sale In Sri Lanka

- Animation Of Hammer Mill

- Zeniths Coal Crushing And Screening Machine