Jaw Crusher Plant With Conveyors

Mobile Jaw Crusher | HXJQ

The mobile jaw crusher plant greatly expands the appliion of coarse crushing, and it combines primary crusher with the secondary crusher (cone crusher or others), which has finer crushing size. The design principle of mobile jaw crusher is to stand in the customer's position, eliminate the obstacles of working sites and surroundings, and offer the facilities with the features of high ...

Conveyor Crusher

For the Mosh hardness of coal is usually under 5, the miners can use jaw crusher, impact crusher, hammer crusher etc. After the coal has been crushed, we need vibrating screen to grade the coal by size and then transport the coal via belt conveyor. In this process, dewatering screen is optional to remove water from the product.

Portable Crushing Plant

Portable Crusher Plant >> EMail: joyal >> Http:// Portable Jaw Crusher plant provides a new field of business opportunities for contractors, quarry operators, recycling and mining appliions. It offers high efficient and low cost project plan without environment limit for .

Mobile Jaw Plants

Our mobile jaw plants are built for maximum jaw crushing mobility. Featuring Pioneer® Series Jaw Crushers, these plants offer up to 25 percent more capacity than competitive models and are equally effective in aggregate or recycling appliions. These plants allow stationary and portable producers to benefit from onsite mobility.

NW120™ Rapid portable jaw crusher

Crusher automation monitors, controls and optimizes the crushing process. NW120 Rapid portable jaw crusher features Metso IC™ crusher automation as standard. The advanced process control system ensures easy and safe use of the plant, as well as enables steering the feeder, crusher and conveyors using a singletouch screen. Optional features

Eagle Jaw Crusher, ElJay Rollercone 45, Screening Plant ...

1. Jaw Crusher Plant. 1987 Allis Chalmers 40"x18' Vibrating Grizzly Feeder, skid mounted. Pan length 14', Grizzly Bar length 4'. 1989 Eagle 20"x36" Jaw Crusher. 30"x27' discharge conveyor. Douglas Manufacturing Magnet. 2. 30"x40' conveyor. 3. Rollercone 45 and 5'x16' Horizontal Screen Plant. ElJay Rollercone 45. Marathon 125HP ...

Tracked Jaw Crushers

Parker tracked primary jaw crushers can be quickly put to work and moved from one loion to another. Available in a range of sizes and fitted with world renowned RockSizer or RockSledger crushers, the single toggle crushing action and design of jaw stock geometry perfected over many years gives impressive outputs when crushing even the hardest of materials.

Wheel type Mobile Jaw Crusher | China First Engineering ...

Wheel type Mobile Jaw Crusher is composed of primary crushing plant and secondary one, belt conveyor, etc. Every crushing plant is an independent working unit. They can respectively assume their different responsibility, and the belt conveyer is responsible for material transmitting and piling up between each crushing plants.

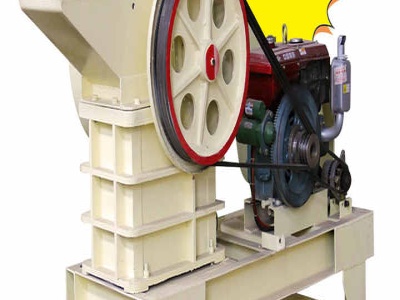

Jaw Crusher

The gyratory crusher can, just like a jaw crusher, accept boulder sizes close to m (for the largest equipment). – This crusher can handle products with a Mohs hardness that is not necessarily less than 5. – As is the case for jaw crushers, there is not any mutual sliding on grinding surfaces, but simply rolling of the nut on concaves.

Jaw Crushers

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher's two jaw; one is fixed while the other makes an eccentric movement. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds ...

crusher | Ritchie Bros.

Details: 1100 mm x 700 mm Jaw Crusher, Folding Discharge Conveyor, Magnet. Make Offer or Buy Now. NETHERLANDS. Friday, December 3, 2021 . View Details on IronPlanet. 2003 Metso Nordberg LT1110 Tracked Mobile Jaw Crusher Plant, Jaw Crushing Plant. Details: Cat .

LOKOTRACK LT106 MOBILE JAW CRUSHING PLANT | .

The ® LT106™ is equipped with the Nordberg® C106™ jaw crusher, which has a proven track record in the toughest of appliions. It offers the best capacity and cost efficiency in the 40tonne size class, with new features such as a radial side conveyor, high inertia flywheels and Metso IC™ process control system that utilises an ultrasonic material level sensor.

jaw plant crush – Mining Machinery Mobile Rock Crusher ...

Jaw Crusher For Sale Complete Jaw Crusher Plants. Jaw crushers are a very well established class of equipment that have been in use for over 150 years since they were first invented and are widely used in quarrying and mining plants to produce construction aggregates or to crush ores.

NW106™ Rapid portable jaw crusher

NW106™ Rapid portable jaw crusher, or portable jaw crushing plant as it is also called, is a primary crusher suitable for reducing hard and soft rock, as well as recycled materials. It is an optimal choice if you want to move the crushing plant from one site to another periodically.

Mobile Jaw Crusher|Track Jaw Crusher Machine Supplier ...

mobile jaw ptj 1176 Puzzolana offers track jaw plant range with a compact, efficient and high output Jaw Crusher Plant. With its user friendly design and quick setup time, it is ideally suited for Mining, Construction and Quarrying industry

RipRap®

Features the widest, heavyduty feeder in the industry, measuring 67"x24' to meet your highest volume production needs. Versatile, 42" reversible cross conveyor allows feeding into the stacking conveyor from either side of the plant and features 5' impact bed and idlers. Available in .

Plant Equipment | LS Quarry

Crushing Plant The Powerscreen® XR400S Setup Time: 30 minutes Area Crusher Takes up: m2 Maximum Feed Size: 600700mm Production Rates: up to 400 tph Features Benefits High output and excellent reduction capability Hydraulic folding feed hopper with boltless fixing system Excellent under crusher access with a hydraulic tilting conveyor system Economical to [.]

TrailerMounted, Portable Jaw Crushing Plant

PORTABLE 3042 CRUSHKING® JAW CRUSHER PLANT. "GIGANTIC" 30" x 42"Jaw Crusher Complete with VBelt drives. 38" X 12' Vibrating Grizzly Feeder: Complete with VBelt drives, 20 HP TEFC electric motor (220/440 Volts, 3 phase, 60 cycle.) .

Maximus 43x27 Static Jaw Crusher, 1100x700 Jaw Crusher ...

The Jaw is now in stock and ready for immediate sale. Maximus 43×27 Jaw Crusher can be purchased today for £43,000. We have drawings and parts manual for this crusher. Ideal Crusher for setting up on a Mobile or Static plant for crushing oversize material or recirculating and crushing down oversize in a crushing and screening line.

Latest Posts

- عملية طحن الفلوريت

- مقبرة غزاة المسافر دليل قديم مطحنة

- كسارة اجزاء الموردين السودان

- كسارة الحجر الجيري تنزانيا

- الصابورة لسعر مصنع معالجة المعادن

- الكسارات ومطاحن الكرة في الفلبين

- معدات تجفيف الرمل المحمولة

- مصنع محجر كامل

- مُصنع محجر الذهب الخام

- والرمل صنع وحدة كسارة صغيرة في المملكة العربية السعودية

- مصنعي مطحنة الكرة الأولية في مصر

- توزيع الحجر في مصر

- ماكينات طوب الرمل

- كسارات صخور مستعملة للبيع في أمريكا

- معدات محاجر خام المعادن

- 1200tph Capcity Vibrating Screen Opening

- Dual Pot Sand Filter Working Principle

- Suspension Raymond Roller Grinding Mill

- Iron Ore Filtering Processing Units In Bulgaria

- China Investors Buy And Sell Sandstone Quarries

- Parameters For Jaw Crusher

- Definisi Simbol Various Crusher

- Large Scale Mining In The Philippines

- The Rock Gold E Ploration Tools

- Por Le Gold Ore Cone Crusher Manufacturer Angola

- Tph Stone Crusher Price In Togo

- Coal Pulverizing Machine Manufacturers

- How To Make Chipper Hammermill

- Shibang Stone Crushers Kenya

- Stone Crusher Plant Manufacturer In El Salvador Price