Grinding Mineral Hammer Mills

ATR (Dry grinding) | Hosokawa Alpine

Typical appliions for ATR mills are mineral fillers, glazing raw materials and nonmineral hard materials. Examples: limestone, quartz, zircon sand, talc, ceramic colours and frits, titanium dioxide, etc. Minerals: The mill is used for the ultrafine comminution of mineral fillers or glazing raw materials. Aluminium oxide grinding beads with ...

Hammer Mills, for All Your Grinding Needs

About Meadows Hammer Mills Meadows hammer mills are durable utility grinders capable of grinding most dry, freeflowing materials. Hammer mills operate on the principle that most materials will grind or crush upon impact with the hammers. The material is fed into a hammer mill from the top and gravity falls into the grinding chamber.

Hammer Mill Crusher Grinder

Feb 25, 2016 · The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher and in these machines ...

Ultra Fine Hammer MillALPA POWDER

The hammer blade installed on the rotor will rotate at high speed inside the hammer mill to crush and grind the material. By adjusting the rotation speed of the hammer and the size of the screen aperture, the grinding particle size of the material is controlled. Share: alpa Inquire ...

Powder Milling and Grinding Processing ...

The hammer mill and pin mill are responsible for the grinding processes, and the dust collector ensures nothing is wasted. At the new plant, the PM6 production line used to mill hot pepper, white pepper, black pepper and cinnamon, is a combination of feeding hopper, belt conveyor, hammer mill, pin mill, cyclone separator, dust collector and ...

Hammer Mill Rock Crusher: Gold Mining/Ore Grinding, Glass ...

16"x12" hammer mill crusher used for crushing and pulverizing hard rock ores, recycling glass or concrete, or pulverizing other brittle material such as ewa...

Verdés Hammer Mills for clay and minerals grinding and ...

Hammer mills are a basic element of clay preparation lines that use dry grinding processes and are especially suited for the grinding of clay to be used in the production of high quality ceramics. Their versatility also makes them suitable for the grinding of other minerals that are capable of being ground to size via an impact crusher.

hammer millGrinding Mill Manufacturer,Grinding Mill for ...

Hammer Mill Working Principle. European version coarse hammer mill mainly consists of frame, rotor, support iron and grate bars. The frame is divided into two parts: upper part and lower part, which are welded by steel plates after being cut. Liners made of high manganese steels within the frame can be replaced after being worn out.

The Working Principle of Hammer Mills (Stepbystep Guide)

Hammer Mill. SaintyCo hammer mills are high precision machines for grinding solid and hard granules. Our hammer mills guarantee uniform grinding, noiseless operation and less heat buildup in all pharmaceutical processes. Whether you need standard or customized hammer mills, SaintyCo offers many series for specialized shredding appliions.

Verdés machines for mineral processing, grinding and crushing

Mineral Processing and grinding machines Mills and Crushers Thanks to our wide range of crushers and mills, the Verdés crushing and grinding equipment can process minerals and materials in large formats and reduce their size to achieve the desired granulometry.

Hammer Mills and Material Size Reduction Equipment

Our Mega Mill Hammer Mill provides uniform grinding with less heat buildup, as well as a bearing and shaft arrangement that ensures smoother and quieter operation. The first product Prater (formerly Prater Pulverizer) developed was a hammer mill, and since that time our company has sold thousands of hammer mills to customers in various industries.

RME · Mill Relinining Equipment · SAG, AG, Ball Grinding ...

RME also has a liner handling solution for the growing number of installations of larger vertical grinding mills. ... RME's THUNDERBOLT Recoilless Hammer, is unlike any other power hammer. ... RME is a technology company capable of solving a wide range of mining and mineral processing plant problems via custom machine system solutions.

How it Works: Crushers, Grinding Mills and Pulverizers ...

Jun 02, 2017 · Hammer mills are a type of impact mills that utilize fixed or swinging hardened steel hammers, chain or a cage. Hammer mills can be used for coarse crushing or fine grinding, depending on the size and configuration. Hammer mills are available in vertical and horizontal rotor configurations with one to many rows of hammers.

Grinding

Grinding equipment for mineral processing. The final fineness of the product mainly depends on the number of times the ore particles pass through the grinder. The longer the grinding, the smaller the particle size. Separate crushing and grinding steps are necessary, the ball mill can only receive the broken ore particle, and then grind to the ...

silica sand grinding mill, raymond mill

Vietnam 4TPH Calcium Carbonate Grinding Line. Material: Calcium carbonate Capacity: 4TPH Output Size: 1250mesh Equipment:.. MB5X Grinding Mill. Hammer Mill.

Comminution | Multotec

The comminution process reduces particle sizes by breaking, crushing, or grinding of ore, rock, coal, or other materials. The process is most often used in the field of mining and / or mineral processing, where mineral ore is broken down into small particles, by hammer, roller / vibrating disc mills and jaw, gyratory and cone crushers.

Continuous Coarse Grinding Equipment and Systems

COARSE GRINDING TECHNOLOGIES. Bepex coarse grinding equipment provides a size reduction solution to produce a product between 1″ and 100 mesh. Although each machine is a hammer and screen mill, they all feature beneficial differences, depending on the appliion. Ultimately, each technology is entirely customizable to your specific appliion.

Grinding

Grinding. The Anderson Feed Technology is the result of over 100 years of experience and development in the cerealprocessing industry. Anderson Feed Technology hammer mills are supremely suited for the milling of products with a fibrous structure and a low density, for example dried alfalfa, straw, etc., as well as composite feeds that have a relatively high fat or moisture content.

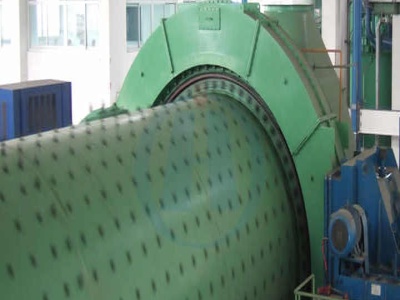

Ball Mills for Mining and Mineral Processing Industry

Feb 17, 2019 · Who We Are. Founded in 1987, ZJH is mainly focus on producing and supply crushers,ore grinding equipment, mineral beneficiation equipment, laboratory and pilot scale ore dressing equipment for Mines and Mineral Beneficiation Plants. Our aim is to work together with the Mining and Mineral Processing Industry for helping to carry on the production technical innovation, to .

Hammer Milling and Jet Milling Fundamentals | AIChE

Select the optimal hammer mill or jet mill for your appliion by characterizing the feed material and conducting milling tests. Size reduction, or comminution, by mechanical crushing and grinding is an important unit operation in the chemical, power, mineral, metallurgical, and pharmaceutical industries.

Hammer Mill

Hammer mill is the machine which can express by its name, Hammer mills are used for grinding almost all types of free flowing materials. Hammer mills operate on the principle that most of materials will grind or crush upon the impact of swinging hammers. The material is feed in to hammer mill from the top and falls in to grinding chamber by ...

Impact pulveriser,heavy duty pulveriser,impact pulveriser ...

We offer precision made range of Pulverisers, Micro Pulverisers, Ball Mill, Hammer Mill, Crushers, Mixer and material conveying equipments, Pharmaceuticals, Chemical, Mineral and Refractory, Pharmaceuticals Grinding Machines, Chemical Grinding Machines, Mineral Grinding Machines and Refractory Grinding Machines and Plants.

Latest Posts

- قائمة فحص محطة تحلية خام الحديد

- قائمة بالآلات بمصنع أسمنت 100 طن يوميا فى مصر

- الكسارات الكوارتز الدوارة في بانغالور

- مصنعي معدات التعدين السودان

- كسارة tph بيع سعر آلة كسارة الحجر

- مصنع لتكسير الحجر في مصر

- الكسارات مخروط الحجر في المملكة العربية السعودية

- الزجاج المعاد تدويره وكتل الاسمنت

- بيع كسارة فكية خام الحديد

- كسارات المعدات المستخدمة في الولايات المتحدة

- حساب الكسارة المغذية الاهتزازية في الجزائر

- mechinery تعدين الرمال الصين

- كسارات الحجارة المستعملة من المملكة العربية السعودية

- تقرير التدريب على مصانع لفائف الصلب

- تستخدم معدات التعدين تحت الأرض مصر

- List Of Ball Mill Parts

- Equipo Toipografico De Uso En Venta En Usa

- Buy Sell Used Cars Online Free In Nigeria

- Cement Grinding Ball Mill Plants In Kenya

- Lljad Tum Mill Gaye Tums

- Acumac Id Grinding Machine Model Aig 50

- Shabao Jaw Crusher Manufacturers Di Pakistan

- Produsen Crusher Primer Untuk Batu

- Using Nanotechnology For Rock Phosphate Processing For Fertilizer Use Aug

- Iron Ore Pelletising Plant In China

- Speco Vibrating Screen Catalog

- Stone Crusher For Sale World Crushers

- Ball Mills For Handling Quartzs Capacity

- Accord Spinning Mills Limited

- Cost Of Pencil Grinding Machine