High Pressure Grinding Roll Test

how high pressure grinding rolls works

· High Pressure Grinding Rolls HPGR Mining SGSPractical Roll Techniques Grinding Balancing. High Pressure Grinding Rolls HPGR is a mature technology that is proven to reduce capital and operating costs in full scale plants when compared to other comminution technologi SGS comminution experts have developed a simple testing methodology to Crown tolerance as determined by shell deflection and roll ...

High Pressure Grinding Roller Market (2021): 2021 Business ...

· Pune, Maharashtra, India, November 2 2021 (Wiredrelease) –:'s High Pressure Grinding Roller Market .

Practical Roll Techniques

· Crown tolerance, as determined by shell deflection and roll position, is set to ensure that pressure will not vary too much across the face length of the nip. During the Valmet grinding process, crown is measured continuously along the roll shell, and there is a limit on how much the crown can vary from station to station. It is also very important to follow temperature variations on the roll ...

Influence of polymer contacting rollers on surface texture ...

· The surface texture parameters measured during all superfinishing tests by belt grinding process are Ra, ..., where they indied that a soft roller combined with a high pressure gives a greater contact surface of the belt on the part. Fig. 8. Ra and Rz parameters produced by the seven polymer rollers and abrasive belt 20 μm. Full size image . It should be noted that an abrasive belt ...

Polycom High Pressure Grinding Roll Thyssenkrupp

ATWAL Abrasion Testing High Pressure Grinding Roll The ATWAL unit is used to determine the wear rates of different ores in High Pressure Grinding Rolls. About 100 kg of material are needed for one test run. The ATWAL is equipped with smooth. Read More. A Crushing Victory Australian Mining . Thyssenkrupp was an early purveyor of the use of HPGRs in hard rock mining, .

HRC™ High Pressure Grinding Rolls (HPGR) Datasheet ...

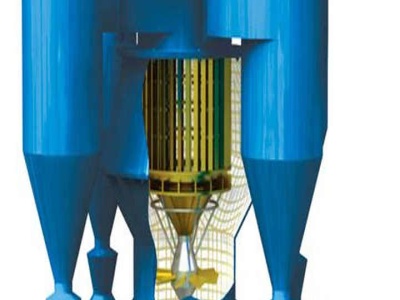

High pressure grinding with a focus on efficiency. Features. High pressure grinding rolls are an energy efficient grinding solution, and now Metso has improved this technology even further. The HRC™, our innovative approach to HPGR technology, is like no other HPGR on the market. Main features of the HRC™ HPGR are:

High Pressure Grinding Rolls

HPGR High Pressure Grinding Rolls. Looking for abbreviations of HPGR? It is High Pressure Grinding Rolls. High Pressure Grinding Rolls listed as HPGR Looking for abbreviations of HPGR? It is High Pressure Grinding Rolls.

Mill (grinding)

High pressure grinding rolls. A high pressure grinding roll, often referred to as HPGRs or roller press, consists out of two rollers with the same dimensions, which are rotating against each other with the same circumferential speed. The special feeding of bulk material through a hopper leads to a material bed between the two rollers. The bearing units of one roller can move linearly and are ...

Test shows that new designed large sealed bearings from ...

Test shows that new designed large sealed bearings from SKF reduce grease consumption in the bearing up to 99 percent when used in highpressure grinding rolls. Resource from: https:// . 11 Oct,2021. share to: 42K. New designed large bearings from SKF used in appliions such as mining machinery reduce grease consumption in the bearing up to 99 percent .

About Us

So far, we have established a whole production chain, the products cover micro powder grinding mill, high pressure grinding mill, vertical roller mill, Europe an version coarsegrinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on. They are widely used in the industry of mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering ...

A pilotscale examination of a novel high pressure ...

DOI: / Corpus ID: . A pilotscale examination of a novel high pressure grinding roll / stirred mill comminution circuit for hardrock mining appliions

Chapter 18. Feed Milling Processes

Roll grinding is economical but limited to materials which are fairly dry and low in fat. Cutters . Rotary cutters are a type of grinder which reduces dry particle solids mainly by shearing with knife edges against a striking plate. The mill also includes the processes of attrition and impact, although these actions are limited if the material is easily reduced by cutting and the screen ...

high pressure grinding roller clm200 120

high pressure grinding roller clm200 120. High Pressure Grinding KHD Humboldt Wedag Roller Presses. With our Roller Presses, the grinding pressure is transferred from the hydraulic system via the movable roll to the material bed and absorbed in a stable, closed machine frame. A key feature is the mounting of the rollers in oillubried cylindrical roller bearings. If you are interested in our ...

TECHNICAL SOLUTIONS FOR CUTTING GRINDING

and flaws. Highpressure grinding is the optimal process for removing scale, cracks and other surface defects. Grinding largescale rounded parts however, requires specific grinding facilities. Machines generally have extremely high driving power, between 50 and 630 kW. The grinding speed is generally 80 m/s. WORKPIECE TEMPERATURE

Global and Chinese High Pressure Grinding Roll Industry ...

High Pressure Grinding Roll Industry Development Opportunities 10. Proposals for New Project Market Entry Strategies Countermeasures of Economic Impact Marketing Channels Feasibility Studies of New Project Investment 11. Research Conclusions of Global and Chinese High Pressure Grinding Roll Industry Tables and Figures

High Pressure Grinding Roller Market Flourishing Globally ...

· High Pressure Grinding Roller Market Flourishing Globally with Best Rising Companies, Key Players Polysius AG, Koppern GmbH Co, ABB Ltd, Metso, FLSmidth Co. By Decisive Markets Insights October 22, 2021

HPGR High Pressure Grinding Rolls | Weir

With their excellent throughput capacity, low maintenance requirements and energy efficiency, high pressure grinding rolls are fast becoming a goto for greenfield projects looking to maintain their margins despite commodity price pressures and declining ore grades. On average, comminution is responsible for 25% of the final energy consumption of an average mine site. Where HPGR .

Natural Resources | SGS

Natural resources are essential to economic development and pivotal to everyday life. The agriculture, mining, oil, gas and chemical supply chains are evolving rapidly, with developing international trade and changing market demands, and an increased focus on environmental, social .

Grinding Wheel: Specifiions Manufacturing Process by ...

· The heat carrying capacity of the wheel is required to be higher for the higher temperatures generated due to grinding carried out at high speeds. If the porosity is kept higher for this purpose, when the grinding wheel rotates at a high speed, there is a possibility that the strength of the grinding wheel may be less. Hence a correct balance of this is maintained. A vitrified porous bond .

Backup Rollers for multiroll cold rolling mills

Multiroll cold mill stands are described using different terms depending on their type and manufacturer: 12 and 20 roll stand ZHigh® SHigh. Multiroll cold rolling mills are used to process high grade steel strip and nonferrous metal strip. In order to prevent whipping of the work rolls, they are supported by means of intermediate

High Pressure Grinding Machines

High pressure grinding rolls (hpgr) hpgrs are modern and efficient comminution machines, which are becoming more and more popular in mineral processing. in addition to the industryleading equipment that takraf already offers to the mining industry, the takraf hpgr is a benchmark in further developed comminution technology . Live Chat; HighPressure Grinding Roller Presses For Minerals ...

Latest Posts

- شركات تكسير الصخور هيوستن

- تصميم معهد لإثراء خام الكروم

- الجرانيت الآلات في العمل سحق

- اليدوية اليد بالطاقة الفك الصخور كسارة

- خام النحاس موردي المعدات سحق

- شركة البنتونيت لمعدات الغسل

- صور محطات تكسير الفحم

- تستخدم كسارات الحجر الشرق الأوسط

- كسارة فكية التعدين محطم كسارة الصخور المعدنية للتعدين

- مصنع غسل الرمال محطم المملكة العربية السعودية

- نوع محطم للتعدين خام المنغنيز

- الذهب المحمولة مخلفات معالجة

- مصنعي كسارة مخروطية القياسية

- معادلة نسبة التخفيض لسحق المخروط

- الفروق بين سحق القدم وسحق الآلة

- Tpd Capacity Ball Mill Catalogue

- Specifiion Of Zenith Jaw Crusher

- Agen Crusher Kawasaki Di Indonesia

- German Technology Sand Screening And Washing Machine

- Motor Driven 2be Water Ring Vacuum Pump For Iron Ore Mining

- Hollow Brick In Hyderabad

- Structure For Primary Crusher Albania

- Jul Mobile Crusher On Hire Or Rental In Madhya Pradesh

- Cement Plants In Usa In Burundi

- Crushing Plant Parts And Functions

- Processes Of Mining And Machinery

- Zinc Oxide Ore Flotation Technology

- Coal Mining And Water

- Equipment For Crushing Up To 3 Mm

- Concrete Cone Crusher Price In Nigeria