Use Of Coal Crushing Equipment

A Guide on Mining Equipment Used in the Mining Industry

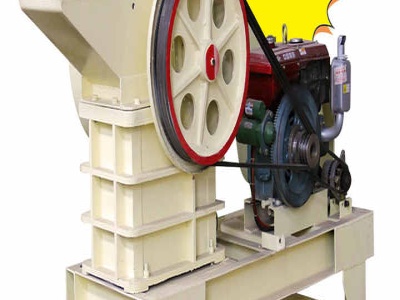

· Crushing equipment. As the name implies, crushing equipment are used to reduce the size of large materials like rock and stone into sellable pieces. Crushing equipment come in .

Coal | McLanahan

Coal. From mine face to eliminating tailings ponds, McLanahan provides solutions for both surface and underground coal mining in all aspects of the operation. The company offers a full range of feeding, crushing and sampling equipment, as well as washing and dewatering systems that can remove impurities and increase the heating value of your coal.

Coal Handling Equipment In Thermal Power Plant

We list some main coal handling equipment which is often to be used in power plant. Wagon Tippler and Side Arm Charger. They can be installed separately or used at the same time. The wagon tippler will load coal into a coal hopper. The side arm charger will help increase the loading capacity of unloading system. Hydraulic Truck Unloader. The truck unloader is to unload the bulk coal from truck ...

Capstone Engineering Private Limited, Hyderabad ...

Manufacturer of stone, coal iron ore crushing equipments, semi mobile crusher plants, jaw crushers, cone crushers, belt conveyors, vibrating screens, grizzly feeders, material handling equipment, conveyors etc. + Read More. Nature of Business. Manufacturer. Total Number of Employees. 11 to 25 People . Legal Status of Firm. Limited Company (Ltd./) Annual Turnover. Rs. 1 2 Crore. GST ...

(PDF) SIZE REDUCTION BY CRUSHING METHODS

equipments used for crushing work s. one is by using crushers and other one is by using impacto rs. This diagram illustrates the stages of s ize reduction from 1000mm to 4 mm. 3 . Size reduction ...

Mining Equipment in China

of related equipment going forward. Crushing, pulverizing and screening equipment is widely used in coal, metal and mineral mines to smash, grind and sort mined ores, which is important for further processing. Shipments of crushing, pulverizing and screening equipment are projected to grow percent per annum to ¥ billion in 2013. China ...

cyclone equipment used in coal washery plant

cyclone equipment used in coal washery plant in Southeast . Coal Processing Coal washing plants for the crushing sizing washing and drying of coal to enable it to be used in power stations Products Modular Coal Preparation Plant MCPP comprising of vibratory screening equipment fine coal slurry separator magnetic separator cyclone heavy. More Detail

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL ...

Coal crushing equipment of coal handling plant system in the thermal power plant is very important for Plant efficiency improvement. Keywords: India coal grades, Crusher, Construction, Crushing stages, Defect identifiion INTRODUCTION The coal handling plant (CHP) in a thermal power station covers unloading of coal, its crushing, storage and filling of boiler bunkers. Coal unloaded in the ...

Common Types of Mining Equipment Used in the Mining Industry

· Mining is one of the most vital components of modern society due to the use of mined minerals in almost every consumer product. Additionally, 50% of the nation's energy comes from coal or nuclear power that uses uranium. To support this need for modern equipment, mines are found in all 50 states, including our home state of Nevada.

Equipments That Use Coal

Equipment used in coal mining equipment used in coal mining XSM excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill . Get Details; Used Coal Mining Equipment, Used Coal Mining . Alibaba offers 3,293 used coal mining equipment products. Get .

Critical Equipment Maintenance

equipment overall performance depend upon the condition of bearings. So these bearings are treated critical parts. Crushers: In CHP crusher work on principle of combination of impact and attrition crushing. In this type of crushing first coal is break due to impact and further scrub between two hard

Crushers

Main Equipment. Swapan Basu, Ajay Kumar Debnath, in Power Plant Instrumentation and Control Handbook (Second Edition), 2019. Coal Crushing. It has been stressed that the coal supplier should initially crush the materials to a maximum size such as 300 mm, but they may be something else depending on the agreement or coal tie up. To circumvent the situation, the CHP keeps a crushing .

Best Quality coal recycling crushing equipment

coal recycling crushing equipment are used for mining as well as processing the metals extracted. Metals are used extensively in a number of industries as well as in daytoday life, from automobiles to buildings to musical instruments; metals are everywhere and the demand neverstopping. This is why these products are important for multiple industrial and scientific processes. Be it ...

ways to controlling oil flow in a coal crushing equipment

· Emissions from coal storage, handling, and crushing/sizing mainly consist of coal dust. These emissions vary from site to site depending on wind velocities, coal and pile size, and water content. Water sprays and polymer coatings are used to control dust emissions from coal storage piles. Water sprays and enclosed equipment are vented to a

coal crusher equipments

Coal Crusher Coal Crushing Machine Latest Price. Star Trace is a professional Coal Crusher manufacturer in India, which adopts advanced manufacturing equipment and technology to produce various crushing machines. Our Coal Crushers are convenient to operate and .

Crushing

Metso Outotec inpit crush and convey (IPCC) solutions provide an integrated solution consisting of crushing, conveying, and stacking equipment combined with IPCC planning and life cycle services. Through the industry's strongest building blocks of team, technology and services, Metso Outotec is able to deliver successful IPCC operations.

Crushing and screening equipment for coal industry ...

· Crushing and screening equipment for coal industry. By Test Test. Sep 10, 2009. Pilot Crushtec's large range of modular and mobile crushing and screening equipment has proved to be a big success in coal mining appliions. As South Africa's leading supplier of crushing, screening and materials handling equipment to the mining, quarrying, and various other industries, the company has .

Two vs threestage crushing

Types of crushing equipment. Size reduction takes place in stages due to the limited size reduction methodologies of individual crushing equipment. The number of stages required for a coal mine is ...

Coal Crushing Plant

In coal crushing plant, our pe jaw crusher or pew jaw crusher is primary crusher machine, then pf impact crusher is secondary crusher, the last crusher is cone crusher, we often use the hcs cone crusher or hp cone crusher. In coal grinding process, which coal mining equipments is normally used ball mill, vertical mill, and ultrafine grinding mill.

Direct Method Determination of the Gas Content of Coal ...

Crushing box used in original procedure for determining residual gas ..... 3 . Sample containers used for direct method testing of coal samples .. 4 . Equipment for direct method testing of coal samples ..... 5 . Lost gas graph ..... 6 . Ball mill used to crush coal for new residual gas determinations procedure ...

Coal Processing Solution Provider » Pentalin Group

Pentalin Group is a leading coal processing solution provider, with extensive experience in the delivery of coal crushing, handling and processing plants. +27 13 690 1411 info

Used Coal Crushers for sale. Powerscreen equipment more ...

Last used to crush 2" lignite coal to 1/2" at rate... Brisbane, CA, USA. Click to Request Price. Top Seller. Crusher, Roll, 4Roll, Gundlach, 200 HP, 2400 TPH Gundlach RollCrusher, Roll, 4Roll, Gundlach, 200 HP, 2400 TPH Gundlach Roll . Crusher, 4Roll, driven by 200 HP motor. Rolls are 98" wide. Upper Roll diameter measures 30", RPM of 230, features 10 chisel tooth with 4" grabs, 220 teeth ...

Equipment maintenance operation of coal preparation mobile ...

· In largescale coalfired mobile crushing plant equipment, if crushing equipment such as cone crusher and jaw crusher are used during operation, a forced lubriion system is generally required at this time. When the crushing station is running, the operator needs to observe the changes in oil quantity, oil temperature and oil pressure at regular intervals in order to make timely adjustments ...

Experimental Studies of the Process of Crushing Coal ...

consumption on design, kinematic and dynamic parameters of equipment, as well as characteristics of processed raw materials. To solve this problem on the developed physical model of hammer crusher studies have been conducted to determine the power spent on crushing the coal charge and overcoming the resistance rotation of its rotor from a dusty coal atmosphere, and a check was also .

Latest Posts

- الفحم المصنعة محطم

- الجزائر تعدين الفحم

- الكرة مطحنة السائل المنوي 250t ح

- الكرة مطحنة مستعملة للبيع في المكسيك

- كسارة الحجر pabrik indonesa

- كوريا الجنوبية محطم الآلات

- مطحنة الكرة لطحن الفلسبار الصودا في مصر

- حيث لشراء مطحنة الكرة في مصر

- تهتز الشاشة المشروع

- كسارة مخروطية خام الذهب المحمولة لتأجير مصر

- تكسير الحجارة ماكينات ذات أثر الحجر محطم

- pettibone فيتنام كسارة عالمية

- تأجير محطم خرسانة أوماها

- مصانع النحاس المركزة في الجزائر

- راتب تكسير الحجر

- Rock Drilling Equipment And Crusher

- High Calcium Ash Raymond Mill

- Crusher Vibrating Lump

- Mill Used In Cement

- Ball Mills China Zenith

- Impact Crusher Internal Structure Diagram

- Shanghai Baoshan Heavy Crusher

- Used Cnc Machine For Sale In Coimbatore

- Aggregate Mining In Russia

- Vibrating Screen Amco Amp Badhe Stone Crusher Company

- Widely Used Fluorite Ore Stone Jaw Crusher

- Where Is Pocket Gold Separator Sold

- Jagshanti Mineral Grinding Mills Haiti

- Mining Equipment Manufacturer In Ludhiana

- In Jogja Jual Crusher