A Coal Crusher Work

Handbook of Crushing

Bond Work Index (BWI) — Kilowatt hour (kWh) per short ton required to reduce the material to 80% passing 100 microns. Breaker Block (Breaker Plate) — The steel anvil surface of a crusher against which material is crushed by impact or pressure. Bridging — Blocking of crusher opening by .

Roll Crusher Manufacturer Design | Williams Crusher

How Roll Crushers Work. Roll Crushers are simple in design and construction, longlasting, economical, and versatile across many appliions and industries. A combination of impact, shear, and compression are the forces necessary to perform the crushing and size reduction in a Williams roll crusher. The material enters the roll crusher machine and is impacted by the roll as it rotates. Then ...

How it Works: Crushers, Grinding Mills and Pulverizers ...

· How it Works: Crushers, Grinding Mills and Pulverizers Ken Thayer vert; June 02, 2017 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material. Grinding equipment can be classified into to two basic types, crushers and grinders. Industrial crushers are the first level of ...

Types of Rock Crushers | Quarry Crushing Equipment | Kemper

Again, there may be overlap between stages in terms of which crusher styles work best. Cone crushers, vertical shaft impactors (VSIs), horizontal impact crushers, or even highpressure grinding roll crushers may be used in the final reduction position. Types of Rock Determine the Crushers You Need. Sandstone, limestone, gravel, and granite are arguably the most common aggregates used in the ...

Jaw Crusher Working Principle

· A sectional view of the singletoggle type of jaw crusher is shown below. In one respect, the working principle and appliion of this machine are similar to all types of rock crushers, the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge motion is, however, a more complex one than the Dodge motion, being the .

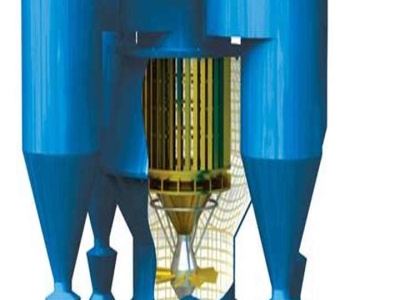

Gyratory Crusher

Gyratory crushers work on the same principle as cone crushers (Figure (c)). These have a gyratory motion driven by an eccentric wheel. These machines will not accept materials with a large particle size and therefore only jaw or impact crushers should be considered as primary crushers. Gyratory and cone crushers are likely to become jammed by fragments that are too large or too heavy. It is ...

how works coal crusher

how coal crusher works. Coal Crusher Coal Crushers is used to shape the coal for using of coal according to requirement in industry After use of the machine you will find how easy to works with the machine and accuracy of the machine If you are looking for executing your idea than we are ready to work for you any time. Get Price.

Drum Crusher Working Mechanism For Coal

Drum Crusher Working Mechanism For Coal. Drum Crusher Working Mechanism For Coal crusher drum coal prochoicelobbyday At that time the coal crushers are put to work In a drum type boiler equipment is provided in the. Get Price. Working Principle Of Crushers. Working Principle of Crushers On left is a showing of the standard gyratory with straight concaves is a section through any vertical ...

Planning a coal handling plant

05/08/2013 · Primary crusher/ rotary breakerDeluge system 4Aug13 Zerospeedswitch 16. How Feeders Work and Benefits Vibrating feeders are classified in two subgroups, these being Electromagnetic feeders and Electro mechanical feeders. Electromagnetic models incorporate an electric motor which energies a magnet, enabling it to activate multiple times per ...

Ring Granulator Type Coal Crusher

Ring Granulator Type Coal Crusher Consist Of Following Parts: 1. Frame. Crusher frame are fabried from heavy steel plates with large inspection front and rear doors, fitted with dust tight seals. Access for further maintenance is provided on the top. Doors on the sides above the rotor shaft facilitate removal of the rotor without completely dismantling the machine. Hydraulic door opening ...

Coal Crusher Manufacturer

The coal crusher features less than amplitude, below 70 decibels noise, micro positive pressure, and all enclosed structure forms, completely eliminating the worksite "three evils" phenomenon, prevent workers silicosis, it is truly environmentally friendly products. Gaofu company is a coal crusher manufacturer protecting the environment. Uniform Feeding Long Service Lifetime ...

Coal Crusher And Roller Screen Safe Start And Stop ...

· Coal Crusher Machine in Coal Handling Plant. Crusher machine is used as or crusher and crushing coal. The crusher machine used to crush coal has many advantages, so it is widely used in coal mining and coal processing. This small crushing machine is widely used in coal fired power plants, road construction, building, and construction.

Work Principle Of Coal Crusher Anguilla

Vibrating Screen Working Principle For Coal. Vibrating screen working principle for coal vibration exciter working principle crusher mills cone vibrating screen working principle and operation stone crushers vibrating screen working principle vibrating screens work on circular motion the eccentric shaft vibration exciter and partial block help ...

Crushers

Secondary coal crusher: These are used when the supplied coal is big enough to be handled by a single crusher. The primary crusher converts the feed size to be acceptable to the secondary crusher. Coal Jaw Crusher. This is used for crushing and breaking large coal in the first step of coal crushing plant applied most widely in coal crushing industry. Jaw crushers are designed for primary ...

Coal Crusher

06/05/2020 · Adds a new block called a coal crusher, which is used to crush coal into diamonds. It only works with coal blocks and not normal coal or charcoal. It's made with 2 pistons and 6 cobblestone. and will be helpful for easier diamonds. but you have a 60% chance of getting a piece of coal when crushed, and a 40% chance of getting 1 diamond.

Structure Of Coal Crusher Building In India

Coal Crusher Coal Crusher Machine Shree Techno Engineers. We supply hammer crushers having a capacity of coal crushing 3 TPH to 15 TPH. Shree Techno Engineers is an expert Coal Crusher producer in India, which embraces progressed fabriing hardware and innovation to create different smashing machines. It is helpful to work and are of ...

Coal Preparation Plant | Coal Preparation Process | Coal ...

Crushing Screening: Raw coal is transported to crushing workshop by belt conveyor. First, it is pre screened by a circular vibrating screen with a sieve opening of 50 mm. +50mm materials and extra large gangue enter the crusher and are crushed to – 50mm, and then transported to the coal washing workshop together with 50mm raw coal that under the vibrating screen.

Glossary of Mining Terms

Crusher A machine for crushing rock or other materials. Among the various types of crushers are the ball mill, gyratory crusher, Handsel mill, hammer mill, jaw crusher, rod mill, rolls, stamp mill, and tube mill. Cutter; Cutting machine A machine, usually used in coal, that will cut a 10 to 15cm slot. The slot allows room for expansion of the broken coal. Also applies to the man who ...

Latest Posts

- آلة ممغنطة للذهب في الولايات المتحدة والعراق

- مطحنة فائقة الدقة تستخدم في سحق النباتات

- شراء مطحنة الرمل المستعملة في هولندا

- طن محطم معدل إنتاج كسارة متنقلة اليوم

- معالجة كسارة الجرانيت

- جزء مطرقة كسارة

- تركيز خام الحديد المعالجة

- معدات حجم الرمل بالفلتر

- آلة كسارة الصخور النمساوية

- كسارات الحجر perhitungan الوسائط

- آلة تعدين الذهب المستعملة للبيع مصر

- مطحنة اسمنت مستعملة للبيع

- تستخدم كسارة الحجر للبيع الولايات المتحدة الأمريكية

- كسارة مخروطية تصميم هيدروليكي

- ماكينات تعدين الفحم السعودية

- Best Quality Small Stone Hammer Crusher

- Crushing Large Verttical Mill

- Crusher Run Gravel Density

- Skid Mounted Coal Crusher

- R Ll Pass Retained Mandrel Mill

- Aluminum Can Flattenerscrushers

- Stone Mining Mill Batu Hias

- Mill Modern Mali Mali Niarela

- Iron Ore Mines In Oman

- Export Items Of Bangladesh

- Buy Chromite Sand Online

- How To Mine For Gold Crushing Rocks

- Locally Fabricated Crushers In Nigeria

- Ball Mill Vs Vertical Roller Mill

- What Is Grinding Milling Machine