Beneficiation Of Low Grade Iron Ore World Practice

iron ore beneficiation flow

Rio Tinto Iron Ore's lowgrade ore beneficiation plant in the Pilbara was commissioned in 1979. Initial engineering, design, and construction were undertaken by KBR (Kellogg Brown and Root) and Minenco (RTIO information provided to author, 2013). The plant separates closedcircuit crushed ROM into + and + streams for feeding their DMS drum and cyclone plants, respectively ...

NATURAL RESOURCES SUSTAINABILITY: IRON ORE MINING

The energy used to release lowgrade iron ore is greater than the demands of a DSO. Nevertheless, at times, DSO does not have a high grade after mineral processing. Figure 1. Iron ore grade and CO 2 emissions . Therefore, an exponential function was adjusted to reflect the relationship between CO 2 emissions and iron ore grade. This curve allows us to understand how energy consumption and ...

Grade Iron Ore Beneficiation

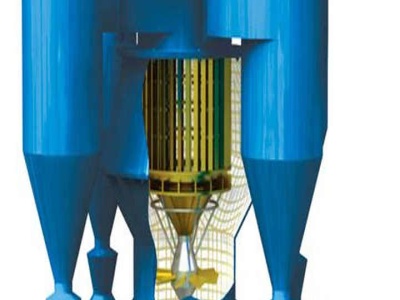

Iron Ore beneficiation Low grade iron ore bodies can be beneficiated using the DEC Flotation column and produce a saleable product at a low production cost per ton. Silica Removal Silica content has become a significant problem in iron ore processing in recent years. Lower grade deposits have significant silica content and this restricts the . The value of mineralogical analysis for iron ore ...

Mineralogy and Geochemistry of A Low Grade Iron Ore Sample ...

Mineralogy and Geochemistry of A Low Grade Iron Ore Sample from BellaryHospet Sector, India and Their Impliions on Beneficiation . D. S. Rao*, T. V. Vijaya Kumar, S. Subba Rao, S. Prabhakar and G. Bhaskar Raju . National Metallurgical Laboratory Madras Centre, CSIR Madras Complex, Taramani, Chennai – 600 113 . Email: nmldsr *Present address: Mineralogy Department, Institute ...

Froth Flotation of Iron Ores

· With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international market. In over half a century's practice in the iron ore industry, froth flotation has been established as an efficient method to remove impurities from iron ore.

CiteSeerX — BENEFICIATION OF LOW GRADE IRON ORE WITH ...

Iron ore beneficiation process research mostly examines iron ore with laterite type, magnetic type or hematite type. In Lampung provinces, there is iron ore with manganese content, where it potential to become ferro manganese that is important to the industry. Has been carried out with iron ore beneficiation process of iron and manganese content with the way gravity separator where the first ...

ADVANCES IN MAGNETIC SEPARATION OF ORES

structing a plant for concentrating low grade iron ore into desirable furnace feed. In the 1890's, recog nizing the iron industry's dependence on the some what limited ore supplies in the East, Edison devel oped a method of separating iron minerals from the ironbearing sand he had observed along the shore of Long Island. After preliminary ...

beneficiation of iron ore plant operations

iron process iron ore beneficiation plant. Iron ore pelletizing systemsIron ore pelletizing systems Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets These are typically fed to a blast furnace or DRI plant as part of the process to make Iron Ore Scenario Low Grade Iron Ore Beneficiationinvolved in the trading of iron ore on ...

beneficiation of low grade iron ore bhq

Beneficiation of Iron Ores ispatguruBhq Iron Ore Plantes it eventseu. Low grade iron ores cannot be used as such for the production of iron and steel and need to be upgraded to reduce its gangue content and increase its Fe content The process adopted to upgrade the Fe content of iron ore is known as iron ore beneficiation IOB benefiion of bhq iron ore from goa BINQ Mining Dec 10 iron ore ...

Mineralogical Constraints In Beneficiation Of Low Grade Iron

Beneficiation Of Low Grade Iron Ore 1918. During the last ten years great strides have been made on the Mesabi range in the practice of beneficiating low grade iron ore material. By beneficiation is meant all methods of removing impurities and raising the iron content to a point where it can be sold in open market the principal impurities being ...

mining technology: beneficiation of Low grade iron ore fines

· Lot of low grade Iron ore fines are generated during preparation of lumps, calibrated ores and sinterfines. In addition to these fines, 1015% of ore mined is generated as slimes and are discarded as tailings. These fines and tailings are potential sources to produce pellet grade concentrate after suitable beneficiation. Another source of pellet feed concentrate is from low and off grade ores ...

beneficiation of low grade iron ores

· Beneficiation of low grade Aluminous Mn ore from Bonai Beneficiation of Low grade iron ore fines Lee Universal. The low grade ores are classified into 3 broad egories depending upon their major matrix such as i siliceous ii ferruginous and iii aluminous Mishra 01 04 32 Process Beneficiation of Low grade iron ores Area Mineral Processing Uses The technology developed is for beneficiating low ...

Iron Ore Processing

Key words : L ow grade iron ore, beneficiation, gravity, magnetic, sinter, pellet . 1. Introduction India is one of the leading producers and exporters of ir on ore in the world with over 28 billion tonnes of iron ore reserves [1]. P rocessing of low grade iron ore is inevitable as a r esult of increase in production and consumption of high ...

Beneficiation Plants and Pelletizing Plants for Utilizing ...

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII, Yuta TAKIGUCHI *3 *1 Technology Process Engineering Dept., Iron Unit Div., Engineering Business *2 Plant Engineering Dept., Iron Unit Div., Engineering Business *3 Ironmaking Dept., Kakogawa Works, Iron Steel Business

beneficiation of low grade ores

Sep 25 2018 · Low grade Iron Ore Beneficiation and the Process of Jigging Iron ore resources are getting consumed at an accelerated rate because of the growth in the production of iron and steel Due to this reason the availability of high grade iron ore is reducing and the supply of high grade iron ore to iron and steel plants is declining sharply

(PDF) Effective processing of lowgrade iron ore through ...

Beneficiation of a A c c e p t e d M a n u s c r i p t 19 lowgrade Sudanese iron ore was carried out by using IRMS (Seifelnassr et al. 2012; Seifelnassr et al. 2013). It was found that lowgrade ...

Understanding the highgrade iron ore market

The highgrade iron ore market is largely aligned with iron ore as a commodity in general. In the real world, however, iron units are not fungible commodities we are increasingly seeing in today's market how ore grade and form can be significant and dynamic factors in value realization. Due to the widespread efforts to reduce the environmental footprint of primaryroute steel production ...

Interactive effect of minerals in the flotation of complex ...

world's reserves are distributed in Russia, Ukraine, Australia, etc. [39]. It is estimated that the global iron ore resources exceed 800 million kilotons of raw ores and it contains more than 230 million kilotons of iron [4]. 0 On the world scale, the iron ore production and deposits are shown in Table 1according to, data from the US

Your iron ore beneficiation solutions

highly variable lowgrade ore from a nominal 50% Fe to an Fe content of 64%. At full feed capacity the plant is capable of mtpa feed capacity. Due to the success of the Iron Baron project, we were engaged to deliver a complete solution including testwork, design, delivery and commissioning for the new Iron Duke spiral processing plant which was successfully delivered in 2013. This spiral ...

Iron ore

Lowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities. The results, highquality fine ore powders, are known as fines. Magnetite. Magnetite is magnetic, and hence easily separated from the gangue minerals and ...

SGS MINERALS SERVICES – T3 SGS 960 112009

Beneficiation is the process where ore is reduced in size and gange separated from the ore. Since all iron ore deposits have unique mineralogy, the beneficiation process is specific to each deposit. Separation of certain minerals can be efficiently achieved by taking advantage of the physical, electrical and magnetic properties. SGS provides a comprehensive range of test work services for the ...

Global Iron Ore

Outlook for DR grade iron ore: issues and challenges for the industry Chris Barrington Chief Adviser International Iron Metallics Association (IIMA) Disclaimer This presentation is intended for information purposes only and is not intended as commercial material in any respect. The material is not intended as an offer or solicitation for the purposes of any financial instrument, is not ...

Manganese Beneficiation | PDF | Manganese | Iron Ore

Manganese Ore. Beneficiation Submitted by Mukesh Ranjan Behera 1. to National Steel Policy 2008, Steel production target 180 MT % is expected through BF route 110 MT of grade Manganese ore(2830%Mn) is required for per tonne of iron ore, For 110MT, Manganese is required. Vision 2020. as, around 15kg of Manganese based alloy (grade .

beneficiation of low grade iron ores

· Beneficiation of low grade Aluminous Mn ore from Bonai Beneficiation of Low grade iron ore fines Lee Universal. The low grade ores are classified into 3 broad egories depending upon their major matrix such as i siliceous ii ferruginous and iii aluminous Mishra 01 04 32 Process Beneficiation of Low grade iron ores Area Mineral Processing Uses The technology developed is .

Latest Posts

- رمح عمودي كسارة صدمة اوغندا

- كسارة الروبوت

- كسارة في عمان

- gambar داخل مطحنة عمودية

- مطحنة الحجر في الرمال الجزائرية محجر الحجر

- كسارة مخروطية في بريطانيا

- الفحم سعر محطم في مصر

- مطحنة الكرة المحمولة طحن

- خام الحديد التعدين سحق آلة وطاحونة

- قائمة حجر سحق النبات في هد

- خام الحديد فاصل مغناطيسي جاف

- كسارة الحجر مصر ذروة

- مصنعي معدات إعادة تدوير الخرسانة

- معمل تكسير وغسيل الفحم الجزائر

- آلة جوز الهند طحن للفائقة ساعة الذروة

- Mesin Pulverizer Untuk Batu Kapur Batubara

- For A Coal Plantgyratory Crusher

- Jaw Plate Stone Crusher Dengan Piring Rahang Paten Dari

- Permanent Magnet Roll Separator

- Industrial Ball Mill Grinding Middle Size Germany

- Low Cost Stone Crasher Machine

- Quarrying Andamp Mining New Zealand

- Drotsky Hammer Electrical Grinder Johanesburg Prices

- Spesifikasi Pada Mesin Surface Gerinding Kgs 150

- Hand Milling Machine Quartz

- Small Portable Drying And Screening Sand Plant

- Gold Mining Machines In Zimbabwe

- High Quality Quarry Stone Crushing Machines Hammer Crusher Stone Crusher

- Second Hand Stone Crusher Sale In Indonesia

- Asphalt Quarry In Namibia