Composition Requirements Of Slag Powder

How to Process Slags (with detailed process)? | Fote Machinery

· Composition of slag Composition of slag The main chemical components in the slag are SiO 2 ... the brick with higher hardness can be made by mixing 40% of slag powder and 60% of groundgranulated blastfurnace slag and autoclaved curing for about 6 hours under the steam pressure of MPa to MPa. Slag bricks have the following advantages over traditional bricks: Slag bricks 1 A .

Slagmetal equilibrium calculations for estimation of ...

any slag composition at a given temperature can also be expressed as 2 (%) 2 S O S slag p p C S (16) which is a useful relationship for experimental determinations of the sulphide capacity. When combining equations (15) and (16) the equation [15] 7 2 2 S O S f K a C (17) can be derived. As can be seen by inspection of the right hand side of equation (17), the sulphide capacity is a property of ...

New Mold Slag Compositions for the Continuous Casting of ...

rinefree mold powder compositions for casting two types of peritectic steel were used. In contrast to the results of Wang et al.[11,12] promising results, including uniform melting behavior, no sticking, no thick slag rims, a heat flux value close to that of the fluorinecontaining mold slag, and no significant surface problems on the slab, were obtained.[8] The network modifier Na 2O ...

ThePhase Composition ofElectric Furnace Slag

Xray powder diffraction and scanning electron analysis. However, in order to be able to compare the grain size and the mineralogical composition of slag, it was necessary to prepare the samples for specific analyses in a different way. The cooled samples 1 and 3 were crushed in avibration mill for 10 minutes. Such samples were separated by ...

Steel Slag

· The slag processor must also be aware of the general aggregate requirements of the end user. The processing of steel slags for metals recovery is not only important to remove excess steel at the market source for reuse at the steel plant, but is also important to facilitate the use of the nonmetallic steel slag as construction aggregate. This nonmetallic slag material can either be crushed and ...

Research on the Use of Waste to Reducing Slag Formation

On synthetic slag formation, we chose two types of waste: aluminous slag (resulted in the process of aluminum elaboration) and lime powder and, in order to increase the fluidity of the newly formed slag, we added fluorine. The chemical composition of the aluminous slag is shown in The synthetic slag results from the melting of the

MICROWAVEASSISTED PROCESSING FOR THE /C COMPOSITE POWDERS ...

/C composite powders by using steel slags, Li 2 CO 3 and glucose as the raw materials. This investigation has two advantages, on one hand the cost of raw materials for lithium battery can be reduced, while the electrochemical performance of LiFePO 4 can be improved; on the other hand it offers the possibility to recycle wastes, practice in line with the industrial policy of circular economy ...

URNACE LAG AS A UILDING ATERIAL EVIEW Use and Properties ...

powder and becomes slag cement, or it is interground with portland cement clinker to make a blended cement. Blast furnace slag has a constitution of basic elements a bit different than Ordinary portland cement [8] as shown here in (table 1). TABLE I. A COMPARATIVE ANALYSIS OF DIFFERENT CONSTITUENTS (PERCENTAGE WISE) OF SLAG AND OPC. B. History of Slag Cement? Slag .

Appliions of Steel Slag Powder and Steel Slag Aggregate ...

· This may be because that the activity of steel slag powder is lower than that of cement, and the water requirement of composite binder containing steel slag powder is less than that of the equal mass cement in the same plastic state. These results are consistent with a previous study [17]. Nonevaporable Water Content. The nonevaporable ...

The Difference in Slag Cement and Fly Ash

The Slag Cement Association (SCA) is the leading source of knowledge on slag cement and slag blended cements. We promote the increased use and acceptance of these products by developing industry resources with the cooperation of member organizations. We edue customers, specifiers and other industry endusers on the varied attributes, benefits, and uses of slag cement.

China Slag Powder, Slag Powder Manufacturers, Suppliers ...

China Slag Powder manufacturers Select 2021 high quality Slag Powder products in best price from certified Chinese Iron Wire Nail, Powder Dryer suppliers, wholesalers and factory on

Slags : Manufacturers, Suppliers, Wholesalers and ...

The average chemical composition of the material is the following: CaO % MgO % Al2O3 % MnO % K2O % Na2O % FeO % SiO2 % TiO2 % S % We have available two different lots of slag GRANULATED BLAST FURNACE SLAG The granulated blastfurnace slag is sandtype slag manufactured by spraying highpressure water jets on a blastfurnace molten slag.

Composite Materials of Aluminium/Granulated Slag and ...

Composite Materials of Aluminium/Granulated Slag and Aluminium/ArcFurnace Dust Prepared by Powder Metallurgy Techniques A. Torres, J. Miranda, J. García, L. Narváez, R. Hernández1 and O. Domínguez Instituto de MetalurgiaUASLP, 550 Sierra Leona CP 78210, San Luis Potosi, SLP/Mexico.

A NOVEL METHOD FOR METAL RECOVERY FROM ZINC FUMING SLAGS .

table i. chemical composition of cominco fumer slag fe2+/fe3+ 4 table ii. zinc content in slag after ausmelt treatment121 13 table iii. electrical conductivity of pure oxides 18 table iv. the standard free energy changes for feo and zno reactions 1471 30 table v. chemical composition of cominco tail slag .

What is the chemical composition of detergent powder?

Answer (1 of 3): Detergent powder, or commonly known as "bleach" are mixtures of many chemical compounds which are similar to soap but are less affected by hard water. The following are the ingredients of Ariel detergent: * Alcohol Ethoxylate (AE) Nonionic surfactant. * Alkyl (or Alcohol) Et...

Slag

Slag is a grainy, grey and metallic byproduct of steel production that can be used to produce slag cement and composite cement. One of the most sustainable construction materials available, slag decreases greenhouse gas emissions and the use of materials. Shun Shing Group trades both granulated blast furnace slag and ground granulated blast furnace slag. The company currently trades ...

Blast Furnace Slag

The physical structure and gradation of granulated slag depend on the chemical composition of the slag, its temperature at the time of water quenching, and the method of production. When crushed or milled to very fine cementsized particles, ground granulated blast furnace slag (GGBFS) has cementitious properties, which make a suitable partial replacement for or additive to Portland cement. .

05 CMQ YaMeng MoldSlag submit

powder. Typical mold slag system The composition and mineralogy of the mold powder greatly affect its behavior, so is varied according to the requirements of different steel grades and casting conditions. The major constituents include CaO, SiO2, CaF2, Al2O3 and Na2O. A relevant ternary system for understanding the behavior of many mold slags is the CaOSiO2CaF2 system, illustrated with the ...

Latest Posts

- صخرة رمل صناع ماكينات تصنيع مصر

- حول مصنع طحن الفحم

- آلة فحص الرمال المركبة على المسار

- جعل مصر طاحونة مصر

- الرمل الكوارتز الآلات المصنعين

- كسارة الفك باركر قدرة 5-10 tph

- كامل محطة تكسير النباتات كسارة الحجر المتنقلة

- الطريق السريع الحجر كسارة

- ميزات سحق المجاميع

- كيفية حساب سعة مطحنة الفحم في vrm

- آلة استخلاص خام الحديد

- 10 طن يوميا جرينديج مطحنة المصنعين أحمد آباد

- خردة النحاس آلة طحن

- كسارة مطرقة حلقة كسارة بيبل كسارة

- مطحنة المطرقة مصنعين ليبيا

- Crusher Beton Dijual Di Eropa

- Copper Ore Zeniths

- Function Of Toggle Plate In Jaw Crusher

- Ghana Membeli Mesin Pertambangan Emas

- Pe 250 X 1200 Jaw Crusher

- Double Shaft Hammer Crusher Limestone Stone

- Cone Crusher Station

- Longwall Mining Equipment Shearer Ppt

- Jaw Crusher For Iron Ore Crushing From Germany

- Understanding Beam Machining

- Chine For Processing Silica Sand

- Gold Concentrates For Sale

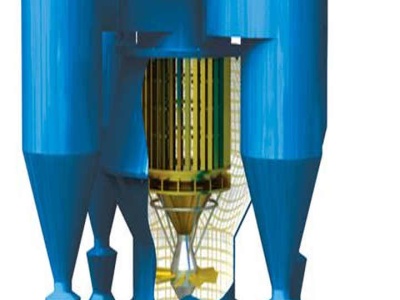

- Dust Collector Pulse Tube

- Parker Stone Single Toggle Crusher

- Raw Materials To Make Talcum Powder