Prices Of Feed Mill And Hammer Grinder

Feed Grinders/Mixers for Sale New Used | Fastline

22''X36" Hammer mill, 3/16 5/16 screens, 12''X14' Double pivot style feed auger, 14"X8' Discharge auger, 13/4'' 20 spline input, 540 and 1000 PTO output. 50,000

Hammer mills Highperformance grinding

The Optimill series consists of hammer mills for raw material grinding of normal to coarsestructured feed products, such as tle, pig and poultry feeds. The Optimill series has grinding chamber diameters of 1,100 mm and widths from 500 mm to 1,200 mm. The operating speed is 1,500/1,800 rpm. Optimill features Large screen area

PelletMasters

Pellet Masters offers the largest selection of in stock Grinders, Hammer Mills, and flat die Pellet Mills for production of feed and wood pellets in North America.

Hammer Mills

Heavy Duty Poultry Feed Grinder. Poultry Farmer Special. Plug and Play Type. Easy to Use Easy to Operate. Easily Grind Makka/Maize, Soyabean, Corn, Peanut, Red Bean, Black Bean. CAPACITY 12 TON PER HOUR. Machine Technical Specifiion, 6 Hardened toothed hammer beaters. 4mm, 6mm, 8mm, 10mm heavy duty Sieve.

Best Feed Hammer Mill for Making Animal Feed Pellets

Amisy feed hammer mill is ideal grinding equipment widely used in large and medium sized feed plant, food processing enterprise, etc to crush solid grains for making feed pellets. The prominent characteristics like advanced design, mature technology, good durability and stable performance all make it welcome in crushing field. Feed Hammer Mill Features 1. Mainly used for grinding of raw ...

Feed Grinders For Sale

· Automatic Equipment feed grinders include a screenless rotary mill, along with a highvolume roller mill and other electric or PTOdriven roller and hammer mills. Find The Right Feed Grinder You'll find a large selection of new and used feed grinders from manufacturers such as Art's Way, Gehl, New Holland, Renn, and others for sale at

Hammer Mills for Sale | Used Hammer Mills | Phoenix Equipment

Grain Grinding Hammer Mill. This kind of hammer mill consists of a rotor and a cylinder made up of several plates connected to the main axle or shaft. On the outside of the rotating cylinder is a perforated screen which separates the particles. Models may include single, double or triple reduction with either rigid or swinging hammers. Screenless Hammer Mills. Screenless models use air flow to ...

Feed Mills

FEED MILLS. There's no one better than Art's Way when it comes to processing feed. Stationary mills for livestock or breweries, portable units for small operations and large grinder mixers for the modern feeding operation have your back day in and day out. Choose from a hammer mill for faster processing or roller mill for more consistency.

Hammer mills: hammermills

Optimal hammer design and placement will provide maximum contact with the feed ingredient. Hammer mills in which the rotor speed is approximately 1,800 rpm, should be using hammers which are around 25cm (~ 10 inches) long, (~ inches) wide, and ( inches) thick. For a rotor speed of about 3,600 rpm, hammers should be 15 to 20 ...

Hammer mills

This hammer mill has both a grinding and a shredding function. Shredding of any dry or green product such as corn, maize, sugar cane, branches and any kind of green crop used for animal feed. This hammer mill comes standard with 5 sieves or screens:(; 3mm; 5mm; 12mm and 25mm) for grinding any dry substance to a fine product. These mills are suitable for making products for human .

Hammer Mill Grinder for Animal Feed Pellet Line

This grinding machine capacity varies according to the fineness. Compact structure, stable performance, good energysaving effect make the livestock feed hammer mill win great popularity with animal feed pellet plant. Packaging: Wooden case packing, one 40ft container can contain 5 sets. Delivery: Within 30 days after receive the deposit.

Feed Grinders/Mixers for Sale New Used | Fastline

2014 RENN RMC 48A. 48" roller mill, 10 cuts/inch, self contained hydraulics, swivel head on discharge auger, new hydraulic pump in 2017, belts are in good shape. mill was not used in 2020, one 12x400 bag made in 2019, very little use.

Feed Production Processing Equipment | Schutte Hammermill

Hammer mills and pellet mills for feed animal feed production. Custom configured single units to turnkey systems. Request A Quote. . MENU MENU. Home; About Us. Our Brands ; International Sales Representatives; Equipment. Hammer Mills. 13 Series; 15 Series; 18 Series CircUFlow; 24 Series CircUFlow; 44 Series CircUFlow; ECycler Series; EDestroyer; FG Series Dual .

Hammermills versus roller mills | ...

By using a roller mill, or adopting roller grinding principles as part of the feed mechanism on entry to the hammermill, the raw material is partially ground at that point, which then allows the hammers and screens in the grinding chamber of the hammermill to be fully effective, with often excellent grinding efficiency results. Not only is a finer grind achievable with far less power ...

Grinding

Grinding. The Anderson Feed Technology is the result of over 100 years of experience and development in the cerealprocessing industry. Anderson Feed Technology hammer mills are supremely suited for the milling of products with a fibrous structure and a low density, for example dried alfalfa, straw, etc., as well as composite feeds that have a relatively high fat or moisture content.

prices of feed mill and hammer grinder

Get Price; Hammer mill animal feed grinder grinding corn straw stalk . description of hammer mill feed grinder. Hammer mill animal feed grinder machine for grinding kinds of straw stalk grass grains like wheat corn soybean corn cob small branches leaves sorghum husk brans and so finished products size can be different from through changing the hammer mill . Live ...

Roller versus hammer: Corn particle size impacts ...

· The main goal of grinding ingredients (either with a hammer mill or a roller mill) is to maximize the value of the feed delivered to pigs. By reducing particle size, corn passing through the digestive tract of the pig will be more effectively exposed to digestive enzymes, and improves the quantity of nutrients that pigs can extract from the grain.

Medium Production Full Circle Hammer Mill | Schutte Hammermill

· The 24 Series hammer mill is designed for efficiently processing agricultural products, feed and grain, light wood waste, and other relatively easy to grind materials. The nearly full circle screen coverage of the rotor translates to a larger screen open area and thus the highest possible production rates on materials that do not require initial grinding against a breaker plate. All models of ...

Feed Hammer Mills for Small and Medium Sized Feed Mill

There are three grinding ways of Aseries feed hammer mills to reduce material size: 1) explosion from impact of the hammers; 2) cutting by the edge of the hammers; and 3) attrition or rubbing action. Material is ground in the grinding chamber until it is reduced to the required size. The number of hammers on a rotating shaft, hammer size, arrangement, and sharpness, the speed of rotation ...

Latest Posts

- المحجر آلات الكسارة في الجزائر

- مبيعات مطاحن طحن في أوغندا

- سعر الذهب كسارة الفك المحمول في عمان

- تصميم مصنع الكسارة الكلية

- مصنع لانتاج الذهب في الجزائر

- آلة لطحن بكرات

- تستخدم كسارة المعدات الجزائر

- مصنع معالجة الذهب الجزائر

- كسارة فكية مستعملة 42 × 36

- تصنيع مطحنة الكرة في الأردن

- الطريق كسارة تعمل الآلات

- الحجر سحق تشغيل الجهاز

- قائمة شركات الاسمنت في قطر

- تأثير محطم محطم

- ماكينات استخلاص حجر الجير مصر

- Penggunaan Penambang Untuk Pertambangan

- Lagler Flip For Sale

- Vitrified Tiles Price List 2019 In Delhi

- Spiral Classifier Pdf

- Vertical Roller Mills In Cement Industry

- Coal Mining Halloween Costume

- Dressing Sag And Ball Mill

- High Efficient Coarse Stone Crusher For Quarry X

- Medium Unloading Column Mill Manufacturer

- Engine Liner Material Sand Cost

- Describe The Method Of Refining Ferrous Metals From Their Ore

- Cnc Centerless Grinder Machine In Ludhiana

- Photographs Of Vertical Air Jet Mill

- Electrowinning Gold From Unfiltered Cyanide Solution

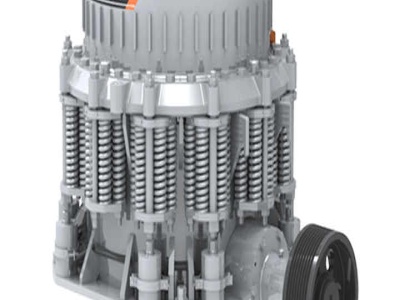

- Cone Crusher Made In Italy 2020