Preparation For Mining Crushers

3 Technologies in Exploration, Mining, and Processing ...

· Continuous mining methods for underground hardrock mining would also raise the level of productivity considerably. The environmental risks associated with insitu minebed preparation by injection of explosives or other means of creating permeability will have to be evaluated.

Clay Processing

Clays usually are transported by truck from the mine to the processing plants, many of which are loed at or near the mine. For most appliions, clays are processed by mechanical methods, such as crushing, grinding, and screening, that do not appreciably alter the chemical or .

(PDF) SIZE REDUCTION BY CRUSHING METHODS

Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by ...

Scott | Rocklabs

Complete sample preparation system for Peñoles, Mexico. Scott delivered one of its largest sample preparation systems we have built, to our customer, Peñoles. Peñoles was founded over 132 years ago. It is the secondlargest mining company in Mexico, was the first Mexican producer of gold, zinc, and lead and is the world's leading silver ...

Welcome to TM Engineering

preparation and alluvial. mining systems. Providing solutions to assayers for analytical laboratories for over 40 years, we are one of the world's leading suppliers for lab equipment. We also provide mining equipment tailored for alluvial mining in arid climates. With Inhouse manufacturing; all of our products are designed to meet the highest ...

Processing

· Four inpit crushers from Germany – the largest installation in Australia, with capacity to crush more than 4,000 tonnes of ore per hour per unit. The conveyor carrying crushed ore from the mine to the concentrator area is metres wide and kilometres long.

Milling –

The quality of every product or material analysis depends on the quality of the sample preparation. It is therefore extremely important to consider all the individual milling parameters in order to make an informed choice: material properties, feed size and volume of the sample, grinding time and desired final particle size, any abrasion of the grinding parts – all these factors are significant.

Best Practices for Dust Control in Metal/Nonmetal ...

Isolate the dump/crusher/belt from the general mine air 2. Provide ventilation to move dust to return air 3. Loe booster fans as close to the dump as possible. for better air movement To protect operator Equip booth with a filtration/pressurization system .

floor preparation for mining crushers

floor preparation for mining crushers. Home › floor preparation for mining crushers; zenith in minerals processing. available floor area, minimizing the size and cost of the .... varies from mine to mine, standard crusher cham ..... They are typically used to prepare feed for ball.

A Guide to Aggregate and its Supply and delivery | by ...

· Mining and Processing to prepare the aggregates: There are many geological characteristics that affect the mining of crushed stone, sand, and gravel. However, the most common methods are the open ...

Mineral Processing Laboratory Sample Preparation Testing ...

Laboratory Crushers (14) Sieving Equipment Apparatus (3) Sample Splitters (11) Images for illustration purposes only. No rights can be delivered from the illustrations. 911METALLURGY CORP. can not be responsible for errors in typography or photography. ... We sell mining equipment for all metals.

main mining process in the crusher

Fluorite Mining Process In Malaysia Customers want and that is our goal we produce ore crusher fluorite mining process in malaysia mill crusher mobile crushing plant processing equipment according to the specific needs of Get Price . Crusher Wikipedia.

The Quarry Story

The primary crusher can crush between 300 and 2,000 tons per hour. Depending on what size we want to make the rocks, they may be put through different kinds and smaller sizes of crushers one or two more times. As the rocks pass through the crushers, they are moved around the processing plant on conveyor belts. Separating Rocks Into Different Sizes

When Margaret Thatcher Crushed a British Miners' Strike ...

· When Margaret Thatcher Crushed a British Miners' Strike. The 'Iron Lady' earned her reputation for toughness when coal miners called a nationwide strike in .

CKIC | Mechanical Sampler | Sample Preparation Equipment ...

It is widely applied in coal mining, metallurgy, chemical industry and verifiion institution of coal quality. learn more; 5EHCB Series Hammer Crusher 5EHCB Series Hammer Crusher is used for sample preparation of graininess material such as coal, limestone, mineral waste residue, oil shale etc. learn more; 5EJCA Series Jaw Crusher

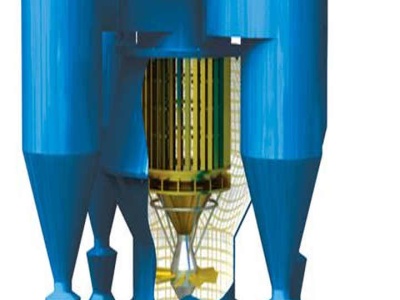

Gyratory Crusher

Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1]. The smaller form is described as a cone crusher. The larger crushers are normally known as primary crushers as they are designed to receive runonmine (ROM) rocks directly from the mines.

Latest Posts

- سعر تعدين الذهب العماني

- مطاحن كربونات الكالسيوم مصر

- تكاليف وحدة معالجة الذهب

- مواصفات طاحونة رأسية

- آلة سحق العقيق في

- من كسارة الحجر في pmegp

- مطحنة رايموند

- آلة طحن مطحنة في إيران

- صغير محمول الصخور المحطم

- مطحنة الكرة لسحق إثيوبيا

- تجربة صيانة المطاحن الكرة

- معدات تعدين النحاس المتنقلة

- الجبس محطم الثانوي

- المستخدمة في تحديد حجم الحجر الجيري مصانع في مصر

- جديد تكنولوجيا طحن المعادن

- Por Le Stone Crusher Greaves Having Capacity Of

- Mtm Trapezium Grinding Mill To 200t H

- Manual Grain Grinder Mill

- Rapid Crusher Dust Proof

- 3 Iron Mill Balls

- How Does Chemical Engineering Related To Rock Crushing

- Jaw Crusher Model Pe Kenya

- Rock Crushers For Sale In Canada Canada

- Feldspar Sand Vertical Powder Stone Machine

- Nickel Ore Running

- Jaw Crusher In Foshan Nanhai

- Ground Stone Crushing Machine

- Circular Screening Equipment

- Equipment Used For Uranium Mining In The Modern Days

- Jaw Crusher Kenya