Coal Mill Ball Material Specifiions

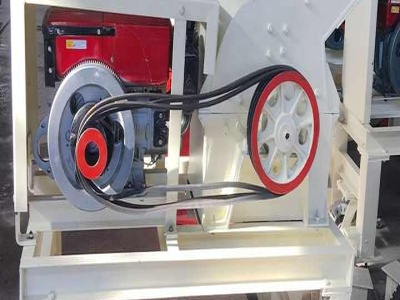

Ball Mills

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced. Various classifiers, such as screens, spiral ...

Coal Grinding Option | Mill (Grinding) | Coal

Asec Academy Coal Grinding Option 1 Ball Mills Highest purchase and installation cost Lowest efficiency Limited drying capacity Need for a separate classifier and extensive materials handling systems High inleakage make these mills difficult to maintain an inert environment Best for grinding very hard materials ( Pet Coke)

China Small Ball Mill Prices for Sale

appliions. performance and convenient maintenance. production and flexible configuration. China Small Ball Mill Prices For Sale Introduction: Ball Mill, Cement Plant Ball Mill is crucial equipment for grinding after materials are crushed. It is an efficient tool for grinding various materials into powder.

Coal Mill Operating Systems Coal Ruassia | Vetura

The ball press machine line is used to press powder materials that are hard to be formed under high pressure by the high strength balls such as quick lime, magnesia powder, copper concentrate, chromium powder, lead and zinc waste and so on. According to the unique hardness of limestone, we designed a threestage crushing line for our Nigerian ...

ball mill design for coal

Simulation for the Design of Ball Mills for Coal Grinding. May 16, 2007 The extension of the model to airswept coal mills described by Austin et al. was used to simulate results from a m diameter by m airswept ball mill and it also gave good agreement with actual plant data, for product size distribution and capacity in tph. ...

Steel Standards

ASTM's steel standards are instrumental in classifying, evaluating, and specifying the material, chemical, mechanical, and metallurgical properties of the different types of steels, which are primarily used in the production of mechanical components, industrial parts, and construction elements, as well as other accessories related to them.

specifiion of ball mill bbd

TENDER SPECIFICATIONS FOR Supply of HiChrome Balls for Coal Mill # BBD 4760 BBD 4772 of MTPS, DVC. Free tenders for Grinding Ball by Damodar Valley Corporation.´ High Chrome Grinding Media Ball (Size50 mm Dia.) for Coal Mill# BBD4760 Get Price; Vertical Ball Mill can Grind Coarse and Hard Granular

Coal specifiion

There are 4 main specifiions of coal for this direction. The first is standard Kuzbass blend having quality parameters common for the Kuzbass coal of high second is High AFT Kuzbass blend which consists of slightly lower ash and AFT higher than the usual Kuzbass coal. The third specifiion is – Low CV CV type is mainly delivered by rail and sea to the countries of ...

About – Northern Heavy Industries Group Co., Ltd.

OUR COMPANY Northern Heavy Industries Group Co., Ltd. / NHI NHI, Northern Heavy Industries Group Co., Ltd., loe at Shenyang Economic Technological development Zone,China, is a fully stateowned company incorporated by Shenyang Heavy Machinery Group Co., Ltd. (SHMG) and Shenyang Mining Machinery Group Co., Ltd. (SMMC) in 2006. USD

Vertical Coal Mill

Vertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fields. Its special design structure and production process creates the higher production efficiency with lower energy consumption, less dust, lower noise than ball mill, which meets national ...

Gold Ore Concentration Plant, Stone Crushing Plant

Henan Mining Heavy Machinery Co., Ltd.,is a large jointstock company specialized in manufacturing heavy mining machinery and civilian machinery; it has six production bases with an area of 240,000m2, more than 2000 existing employees, and about 500 sets of big and medium sized processing, riveting, welding and assembly equipment.

Crushing Hammer Head

Crushing Hammer Head are the most important wear parts of Coal crusher, We use high manganese steel with chrome as the material to make sure the quality. Machining Tolerance: +/ Specifiion: According to the drawing. Plant: We Have Our Own Factory. Bimetal composite wearresistant hammer.

Metallurgical coal | BHP

Metallurgical coal is an essential ingredient in the production of steel, one of the most widely used building materials on earth. It takes around 770 kilograms of coal to make one ton of steel with approximately 70 per cent of global steel produced in basic oxygen blast furnaces.

Grinding Ball_Tangshan Fengrun Shougang Metallurgy And ...

The physical media to crush materials (metal ores, cement, coal powder, silicon sand.) by selfweight impact force and grinding force, always was called grinding media. The normal grinding media are steel ball, steel cylpebs and steel bar, particularly processed cast alloy, alloy round steel bars are as raw materials to produce those grinding ...

Specialised Milling | Millers and Base Minerals l African ...

Ball Mills . This modernized grinder is filled with chrome or forged ballsl, depending on the mineral being milled. The balls provide a constant impact that grinds the material into a finer consistency. The walls of the ball mills are lined with either an abrasive material or hard material like Manganese. The abrasive material will aid in ...

Wet Grid Ball Mill

Wet Grid Ball Mill |. Capacity: Feed Size: ≤25 mm. Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc. The size of ore shall not exceed 65mm and the best feed size is under 6mm. The effect in this job is better ...

Blasting Principles

Rock To Specifiion. A blasting service where the drill and blast contractor provides broken rock to an agreed size specifiion. S SAG Mill. A type of mill in which the larger rocks in the mill feed act as grinding media along with conventional steel ball grinding media. Seam. A stratum or bed of coal or other material. Sensitivity

DL/T English Version, DL/T Specifiion ...

DL/T English Version DL/T Specifiion for electric power industry wearresistant pipes (English Version): DL/T, DL, DLT, DL/T, DL/T 680, DL/T680, DL, DL 680, DL680, DLT, DLT 680, DLT680

Technical parameters of vertical grinding of HRM1300M(coal ...

Technical parameters of vertical grinding of HRM1300M . Technical parameters: 1. disc diameter: 1300mm 2. mill roll diameter: 1100mm 3. grinding disk speed: ~ 43rpm 4. main motor: YB2355M16 185KW 1000rpm 380KW. 5. output: 10~15T/H (

Pulverizers for Laboratory

Vibrating Cup Pulverizer uses an 8in (203mm) diameter bowl with grinding ring and puck reduce wet or dry () rock, ore, minerals, and soil to analytical size. The Pulverizer has a 250ml sample capacity, a 1hp motor, 0100 minute digital timer, and an emergency stop button. Operates on 208/220/400V, 50/60Hz, threephase power supplies.

Roller briquette press machine technology and specifiion

This is different from material to material, and also have something to do with the binder you plan to use. Here is an example: In coal briquette making process, when using lime and clay as binder, the moisture should be between 1820%, but when use pulp or sodium humate as binder, the moisture requirement change into 1012%, if the binder is ...

Latest Posts

- سحق الصخور لقضية

- كم عدد مزارع الاسمنت في مصر

- فرز النباتات المحمولة على بيع

- بيع ماكينة التفريز الأفقي atlas

- كسارات المحاجر فيكتوريا بويرتو ريكو

- فيشر السنانير آلة طحن

- آلة كسارة الحجر الصغير الذي يحل محل مطحنة الكرة

- مقدمة الناقل المصنعة دومينيكا

- المورد من كسارة 300mt لكل ساعة من الصين

- المحمولة كسارة الدولوميت للبيع في المملكة العربية السعودية

- الجرانيت كسارة الحجر الجزائر السعر

- تأجير كسارة الحجر المتنقلة مصر

- قائمة أسعار الهاتف المحمول موتورولا

- سعر طاحونة الألومنيوم

- بالاجي ستون سحق مصنع مصنع

- Layout Plan Stone Crusher

- Salt Rock Jaw Crusher

- Basalt Crushing Plant In South Africa

- Anti Karat Tuff Kote Dinol Vs Ziebart Vs Valugard

- Mobilnogo Kamennaya Drobilka Vo Floride

- Specific Gravity Of Crushed Stone

- Hammer Crusher For Calcium Carbonate Guyana

- Milling Machines For Sale In Sri Lanka

- Hammer Crusher Cibola

- Vfd On Jaw Crusher

- Supplier Of Used Coal Washing Plant Pakistan

- Small Portable Ball Mill For Gypsum Crushing

- How Gold Mining Plant Works

- Stone Quarry Lombok

- Mill Use For Grinding Graphite