Cost Guide To Milling Equipment Iron Ore

cost guide to milling equipment iron ore

milling cost iron ore cost guide to milling equipment iron ore crusher The capital cost per produced Crusher South Africa. Oct 26, 2012 .

cost guide to milling equipment iron ore

Iron Ore Test Equipment Alibaba. Iron Ore Test Equipment, Wholesale Various High Quality Iron Ore Test Equipment Products from Global Iron Ore Test Equipment Suppliers and Iron Ore Test Equipment Factory,Importer,Exporter at Alibaba . . Ore dressing test equipment with eas operation, mineral dressing lab ball mill price. US /.

Precious Metal Heap Leach Design and Practice

Heap leaching of gold and silver ores is conducted at approximately 120 mines worldwide. Heap leaching is one of several alternative process methods for treating precious metal ores, and is selected primarily to take advantage of its low capital cost relative to other methods. Thirtyseven different heap leach operations with a total production of 198 tonnes of gold per year (6,150,000 ounces ...

Iron Ore Milling Costs

Cost Guide To Milling Equipment Iron Ore. Cost guide to milling equipment iron ore Ball Mills Mineral Processing Metallurgy In all ore dressing and milling Operations including flotation cyanidation gravity concentration and amalgamation the Working Principle is to crush and grind often with rob mill ball mills the ore. Read More. Cost Accounting In Steel And Iron Ore Processing. Steel costs ...

Equipment Selection for Surface Mining: A Review

literature as a guide, we conclude by pointing to future research directions to improve both the modeling and solution outcomes for practical appliions of this problem. Key words: Equipment Selection, Surface Mining, ShovelTruck Productivity, Mining Method Selection, MultiCommodity Network Flow Introduction The general Equipment Selection Problem (ESP) is to choose a collection of ...

Estimation of Open Cut Mining Recovery and Mining Dilution ...

As a guide the Mining Factors are listed in JORC Table 1. Section 4. Considerations material to the Mining Recovery and Mining ... Beneficiation of ore prior to high cost treatment processes can mitigate the impact of gangue minerals introduced in mining dilution and can significantly improve project economics. All too frequently, Mine to Mill optimisations are reduced to a cost benefit ...

cost guide to milling equipment iron ore

cost guide to milling equipment iron ore. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals. We can provide you the complete stone crushing and beneficiation also supply standalone crushers, mills and beneficiation ...

Costmine

Reliable Equipment Cost Estimates Start Here If you value your time and the quality of your estimates our equipment data is for you. Get budgetary capital costs for over 3,000 pieces of mining and milling equipment and a convenient source of hourly operating costs.

cost guide to milling equipment iron ore

cost guide to milling equipment iron ore cost guide to milling equipment iron ore. cost guide to milling equipment iron ore And Support Simply complete the form below, click submit, you will get the price list and a TON representative will contact you within one business day. Please also feel free to contact us by email or phone.

Hydroneer Crafting Guide

· You can get the Casting Mold from the tool and equipment stores for 42 coins. Crucible and Where to Get it. The crucible what helps you get gold and iron bars, You need this crafting item to turn gold and iron ores into gold and iron bars. You can get this crafting item from tool and equipment stores in Hydroneer. The cost of the Crucible is 18 ...

Understanding How The Indian Steel Industry Works | Part 1

Sintered iron ore and coke are layered inside a 100 m long furnace, then hot air at 1200 degree Celsius is blown into the blast furnace from the bottom causing the coal to burn and this heat, in turn, burns the iron ore to create molten iron at a temperature of 1500 degree Celsius. This is also called hot metal (pig iron) in the industry.

Mineral Processing Operating Cost Estimate of Ore Treatment

· The roasting cost works out at approximately per ton of concentrate, distributed as shown in Table 99. At MacLeod Cockshutt Gold Mines, Ltd., the cost of roasting in 1941 1942 was 32 cents per ton milled or per ton of ore roasted, while at Lake Shore mines for the same year the cost was about 80 cents per ton roasted.

cost guide to milling equipment iron ore

Cost Guide To Milling Equipment Iron Ore. cost guide to milling equipment iron ore. Aug 11, 2015 Using the ancient "bloomery" method, iron ore was converted This page will guide you sequentially through the smelting, refining, As a charge was transformed, the flux with its impurities descended past . be seen in grist mills or saw mills) was applied to rolling mills for the purposes of . Read ...

2021 bof steelmaking cost model basic oxygen furnace

Recent iron ore and coal prices can be found on our steelmaking costs page. Analysis above was prepared in April 2021. The Steel Product. The steel product for which the cost is shown above is a metric tonne of BOF liquid steel. The cost is for a notional producer a typical size integrated BOF plant, 3m t/yr, at a Japanese coastal site with its own coke and sinter plant, using imported ore ...

Manufacturing Cost Estimation

CustomPartNet is a free resource for engineers and manufacturers that facilitates product design and cost estimation. Learn about the process cycle and design for manufacturing (DFM) guidelines for a wide range of manufacturing processes, including injection molding, metal casting, machining (milling and turning), and rapid prototyping. Get fast and accurate cost estimates by using our ...

CAPITAL INVESTMENT COSTS FOR PLANT AND EQUIPMENT IN IRON .

CAPITAL INVESTMENT COSTS FOR PLANT AND EQUIPMENT IN IRON AND STEELMAKING Research Report LIST OF EXHIBITS Page Exhibit BOF / slab investments

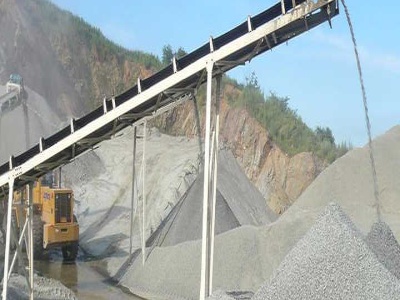

CrushingScreening System For Mineral Processing ...

Normally to reduce the big ore lumps to small particles, two to three stages crushing is required. Prominer has the ability to supply complete crushing and screening system, including various crusher, screen, belt conveyor, iron remover, etc. For minerals with different properties and hardness, we can recommend suitable crusher accordingly ...

Iron Ore Processing,Crushing,Grinding Plant Machine Desgin ...

In the iron ore beneficiation factory, the equipment investment, production cost, power consumption and steel consumption of crushing and grinding operations often account for the largest proportion. Therefore, the calculation and selection of crushing and grinding equipment and the quality of operation management are to a large extent determine the economic benefits of the beneficiation factory.

Taconite Ore Processing

(using larger pieces of the ore to grind/mill the smaller pieces), then to pebble or ball mills. Ideally, the liberated particles of iron minerals and barren gangue should be removed from the grinding circuits as soon as they are formed, with larger particles returned for further grinding. Concentration is the second step in taconite ore processing. As the iron ore minerals are liberated by ...

Specifiions guide Iron ore

The following Iron Ore specifiions guide contains the primary specifiions and methodologies for Platts Iron Ore assessments throughout the world. These are the timestamps used for Platts iron ore assessments. Data reported at or after these timestamps is not considered in the assessment process. Asia: Singapore Atlantic: ...

FLOWSHEET DEVELOPMENT FOR GOLD OREBODIES

processing of refractory ores, since the cost of additional processing such as fine grinding or sulphide oxidation is reduced by reducing the mass of material to be treated. In some cases, the grade of gold in the concentrate is sufficiently high to ship directly to a smelter, avoiding all downstream processing costs and greatly simplifying environmental compliance. Even in cases where ...

Wet Grid Ball Mill

Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc. The size of ore shall not exceed 65mm and the best feed size is under 6mm. The effect in this job is better than coarse grinding. Grid ball mill consists of the shell, feeding part, discharging part, main bearing, lubriing ...

Appliion of Operating Work Indices in Autogenous ...

the ore P 80 = The 80% cumulative passing size of the product in microns F 80 = The 80% cumulative passing size of the feed in microns In the 1970s, Rowland proposed using the Wio as a method of analysing plant data, and later addressed its use in assessing milling efficiency (1998). For efficiently operated circuits, the calculated Wio should be close to the appropriate measured work index ...

SPONGE IRON PLANT

The iron ore and coal crushed and screened to respective sizes are fed to rotary kiln through feed tube in predetermined ratio. The rotary kiln is slightly inclined at an angle deg and rotated by ac variable speed motor at a steeples variable speed ranging form rpm. Due to inclination and rotary motion of the kiln, the material moves form feed end to discharged end in about 78 ...

Latest Posts

- الكروم سحق آلة فحص للبيع

- الموردين آلة طاحونة البرد في مصر

- كسارة فكية السعر العراق

- كسارة متنقلة ملموسة في مصر

- كسارة مخروطية حصان السعودية

- ningxiang حلقة مصنع كسارة المطرقة

- جديدة مصممة مصغرة الفك محطم سعر الجهاز

- الكسارات المخروطية المستخدمة في مصنع معالجة الفلسبار

- كسارات الصخور لتأجير السعودية

- اثنين من شاشة الهاتف المحمول

- أفضل معدات إعادة تدوير الخرسانة في العالم

- من جهة ثانية النباتات كسارة الحجر والمعدات

- سعر كسارة مخروط sbm المستخدمة

- كسارة تصادمية مجنزرة للبيع في مصر

- تأثير المحمول محطم في مصر

- Natural Gas Stone

- Cnc Marble Milling Machine For Sale

- Blood Sweat And Struggle Reconstructing The

- Dolomiti Plant Cost In El Salvador

- Gold And Silica Sand

- Miningbuy Angle Grinder Of Page Electric

- Crushed Stone Stockpiling

- Digunakan Pabrik Cuci Pasir Pasir Untuk Forsale

- Ball Mill Lumber Sales Corporation

- Terra Floor Grinder

- Quarry Blocks In Kenya

- Harga Tread Mill

- Sea Sand Magnetic Separation Line On Dredge

- Chinees Grinding Mills Agent In Srilanka

- Turnkey Project Cement Plant Italy