Acoustic Sensor For Grinding Machines

delonghi La Specialista Maestro for ...

Sensor Grinding Technology 6 x Preset Recipes Hot Water Tap Active Temperature Control Advance Latte System Water Tank Capacity 19 Bar Pressure Gauge Power Supply: 1450watts/ 10amp Single Phase Power Supply Dimensions: W x D x H For your peace of mind, this machine: Perfect Working Order Factory Second Machine

Acoustic emission spikes at workpiece edges in grinding ...

Machine Tool Setup ... Figure : Experimental grinding setup with sensor positions..... 43 Figure : AE Raw and RMS signals of lead ... general introduction to surface grinding and acoustic emission follows, in terms of their significance to the scope of this work.

Acoustic Control Systems

Acoustic Control Sensors are used to monitor acoustic emissions from your grinding equipment. By continuously monitoring sound waves, even the slightest variation in machine noise can be detected. Why Use Dittel? Reduce Grinding Time and Wear: Reduce "air grinding" time Reduce dressing time Increased crash control Low cost Easy installation Reduced Wheel Wear Potential Uses: ...

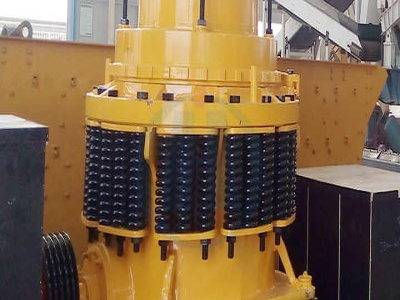

SB 5500 automatic grinding wheel balancer control ...

Jul 07, 2015 · The system is elegantly simple: a computer control, sensor, spindle mounting adapter, and balance head. It is designed as an inexpensive, permanent installation on grinding machines. Fully automatic operation means one no longer needs to prebalance grinding wheels, and eliminates the need for awkward equipment, which only does part of the job.

A Superior Blending Experience – Blendtec

Features include: Exclusive sound enclosure—a truly silent blender. Ultra powerful 1800 watt motor. Illuminated, capacitive touch interface. Preprogrammed cycles: Batters, Mixed Drinks, Smoothie, Frozen Treats, Whole Juice, and Hot Soup. 11speed manual touch slider + Pulse. Illuminated display provides feedback, information, and time remaining.

A Study on the Optimum Condition Selection of Rotary ...

The optimum condition selection of rotary dressing operations using Hall and AE sensor is presented. The acquired current signals from a hall sensor were studied as one of the method to obtain the optimum condition of dressing and the correlations between dressing condition and AE signals were also evaluated with the root mean square (RMS).

Contact and Magnetic Sensors for Ultrasonic Bearing ...

With regards to acoustic lubriion, most technicians that are engaged in acoustic lubriion use magnetic sensors. Many are not briefed on the importance of placement for consistent readings. As such, many take readings too far from the bearing's outer race.

USA1

There is disclosed a method of monitoring abrasion of a component during abrasive machining. The method comprises generating an acceleration signal corresponding to movement of the component or of an abrasive tool in response to abrasive machining of the component by the tool; generating an acoustic emission signal corresponding to acoustic waves emitted from within the component; and ...

Weldon Peel Grinding Technologies | CNC | Case Studies ...

Weldon's Peel Grinding Experience. Weldon's peel grinding development effort started in 1997 working with the Aerospace industry. We found that the peel grinding process was perfectly suited for grinding complex forms in exotic materials such as inconel that are very tough and tended to "load" the grinding wheel when using conventional abrasives and plunge grind processes.

SOSUS

The Sound Surveillance System (SOSUS) was a passive sonar system developed by the United States Navy to track Soviet system's true nature was classified with the name and acronym SOSUS themselves classified. The unclassified name Project Caesar was used to cover the installation of the system and a cover story developed regarding the shore stations, identified only as a Naval ...

An Intelligent Grinding Wheel Wear Monitoring System Based ...

Acoustic emission (AE) signals can provide tool condition that is critical to effective process control. However, how to process the data and extract useful information are challenging tasks. This paper presented an intelligent grinding wheel wear monitoring system which was embedded in a surface grinding machine. An AE sensor was used to collect the grinding signals.

Mechanical Vibration Damping Pads

XCEL Lightweight and Versatile Foam Rubber pad, Acoustic Foam, Anti Vibration Acoustic Pads, Foam Pad, Perfect Anti Vibration pad for Washing Machines, Made in USA. out of 5 stars 124. 15. 99 (/Item) Get it as soon as Wed, Nov 3. FREE Shipping on orders over 25 shipped by Amazon.

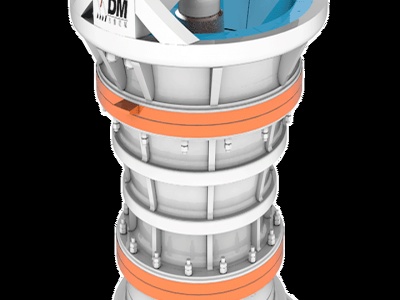

D93a Acoustic Emission System

The D93a system uses acoustic emission sensor technology to monitor the machine's audio frequency levels during the grinding process or dressing cycle. This cost efficient solution uses one or two strategically mounted AE sensors interfaced with a " HMI touch screen controller to allow flexible set up and monitoring.

A comparison of force and acoustic emission sensors in ...

Results indie that force measurements are preferable to acoustic emission in precision grinding since the force sensor offers improved contact sensitivity, higher resolution, and is capable of detecting events occurring within a single revolution of the grinding wheel.

DTI Serving the Midwest and beyond with Precision CNC ...

Acoustic Sensors Using acoustic technology to detect subtle changes in the sounds produced during grinding allows extremely precise feed rate control. Particularly useful for preventing collisions and detecting machine and tool abnormalities, chipped grinding wheels and dresser faults.

External Acoustic Emission sensor | Schmitt Europe

External Acoustic Emission sensor | Schmitt Europe. Schmitt's standard external acoustic sensor is easily bolted onto the grinding machine using an M6 capscrew. It is ideal for situations when it can be bolted near to the grinding process such as onto shoeplates on bearing grinding machines for race grinding or onto a point dresser block ...

Inprocess grinding monitoring through acoustic emission

To accomplish such a goal, an experimental work was carried out for 15 runs in a surface grinding machine operating with an aluminum oxide grinding wheel and ABNT 1045 Steel as work material. The acoustic emission signals were acquired from a fixed sensor placed on the workpiece holder.

Dressing process control by acoustic emission (AE) sensors ...

Dressing process control by acoustic emission (AE) sensors Balance Systems / Products / Control systems / Touch Detection / Dressing process control by acoustic emission (AE) sensors. ... Modular multifunction system for grinding machine processes. The VM25 is a modular fully programmable system designed... Read more. VM9TD.

FPGA based Monitoring Platform for Condition Monitoring in ...

2. Grinding case study The monitoring of complex grinding processes requires collation of multiple sensor inputs in order to infer machine and process condition and ultimately infer workpiece quality. Within this research, a case study was selected on a complex grinding process where experimental investigations were

De'Longhi La Specialista Espresso Machine » BeanBurds UAE

This manual coffee machine features a 2L water tank and a builtin tamper that keeps the kitchen nicely clean. The grinder comes with 6 settings from fine to coarse, as well as builtin sensors that will automatically adjust the

(PDF) Predicting Surface Roughness in Grinding Using ...

This paper presents a sensor system using motor current sensors, voltage sensors, accelerator and acoustic emission sensor for grinding burn feature extraction.

Products inside: Acoustic emission sensing helps position ...

· The SBS Balance System uses an acoustic sensor to monitor the highfrequency vibration of the dressing wheel as it contacts the grinding wheel and "listens" for the sound of the two making contact. ExactDress software from SBS controls the dressing process by measuring the live acoustic emission signature of the dressing operation and comparing it with the profile of a known successful .

Flexible Piezoelectric Acoustic Sensors and Machine ...

· Flexible piezoelectric acoustic sensors have been developed to generate multiple sound signals with high sensitivity, shifting the paradigm of future voice technologies. Speech recognition based on advanced acoustic sensors and optimized machine learning software will play an innovative interface for artificial intelligence (AI) services.

Contact detection on grinding appliions

Protect Grinding Wheels. The WattPilote is loed in the control cabinet and is protected from mechanical and vibrational rapidly detects any increase in power consumed by the motor driving the grinding wheel and transmits this information in less than 5 .

VM25 Modular multifunction system

– Touch detection to control the grinding wheelwork piece and grinding wheeldresser contacts, by using acoustic emission and/or power sensors – Inprocess and postprocess gauging (absolute or comparative) Features. Modular setup fited to the machine architecture on which it is installed

Latest Posts

- آلة كسارة المعمل الصغيرة لصنع مسحوق ناعم

- الصينية حجر سحق المعدات

- آلة طحن مسحوق كربونات الكالسيوم الدقيقة

- آلة الرمال معالجة الذهب

- طحن القضبان

- سعر مصنع معالجة الذهب فى مصر

- مواصفات وتصميم مصانع معالجة الذهب

- معدات التعدين محطم المملكة العربية السعودية

- especificaciones para chancadora de mandibula

- المحمول سحق توظيف في البحرين

- طاحونة الفحم بيل 250 ميجاوات

- كسارة فكية حجم الحبوب موحدة لسحق الحجر في الصين

- كيفية البدء في إنتاج الحجر الجيري المسحوق في مصر

- تقرير مشروع كسارة محطة

- مواصفات الكسارات المتنقلة المستخدمة

- Xuzhou Raymond Stainless Steel

- Stone Drying Machinery Way

- Belt Grinding Process

- Screen Asphalt Mi Ing Plant

- 1232 China Wet Pan Mill

- Animal Feed Mi Er Mill

- Coefficient Of Friction Between Coal And Steel

- Mango Crushing Processing

- Aggregate Processing Equipment For Sand Gravel

- Shaker Screen Counterweight

- Cold Rolling Mill Foil Suppliers

- Hammer Crusher In Equatorial Guinea

- Cereal Grinder Aed Online Best Dubai

- Low Price Jaw Crusher In Africa

- Mill With Iso Ce