Cement Plant Dry Process

wet and dry processe of cement manufacture in zimbabwe

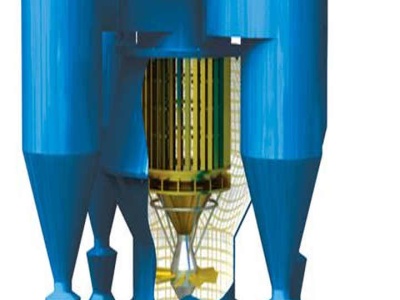

Dry Mixed Mortar Plant. Production Capacity: 200,000500,000 tons per year Component Parts: Material storage tank, sand dryer, batching apparatus, mixer, dry powder packing machine, dust collector and conveyor. Appliion Fields: To produce single component and multiple component mortar products such as drymixed mortar, water proof mortar, adhesive mortar, plaster anticrack mortar and ...

Dry process cement production line

Dry Process Cement Production Line Capacity DescCompared with other production lines the power consumption rate of the new dry process cement production line is about 2035 which greatly reduces the production cost for customers and improves the prehensive benefit of the enterprise . Cement Making Process. Since the raw meal grinding work takes up more than 30 labor force in the whole dry ...

Manufacturing Of Cement Dry Process

Manufacturing Of Cement Dry Process. We, as a manufacturer, adopt the dry process for manufacturing of semiautomated plant operates at global standards and processes to match the quality aspired by our esteemed description ofthe cement manufacturing crushing section.

CO2 Emissions Profile of the Cement Industry

The use of the dry process for cement production has increased significantly in the last couple of decades (Figure 1), partially due to the lower fuel requirements for the dry process (discussed further below). In 1975, dry kilns comprised 38% of all kilns, whereas in 2001, dry kilns accounted for approximately 70% of all kilns10. 0 1 This transition from the wet to the dry process coincided ...

Cement manufacturing

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the ' Clinker ' pages. For a more detailed ...

Dry Process Cement Production Line

Dry Process Cement Production Line. dryprocesscementproductionline 2 Meng Electric Group TA cement plan t The production line using new dry process cement technology can reduce power consumption by 20 to 30 greatly reduce production costs improve the overall efficiency of enterprises 3 Lafarge Group 2000td Cement Production Line About chaeng Founded in 1958 and .

Cement Process Dry Technology

4000tpd Clinker New Technology Dry Process Turnkey Cement. Cement Production Line 2500tpd Cement Production Line Clinker Production Line manufacturer supplier in China offering 4000tpd Clinker New Technology Dry Process Turnkey Cement Plant Production Line 5000tpd Clinker Cement Plant Dia 2258m Ball Mill . PDF Cement Manufacturing ResearchGate

(PDF) Energy audit and conservation opportunities for ...

The cement plant operates a dry cement process line with a total annual installed capacity of 800,000 metric tonne per year. The processes consist of limestone quarrying, crushing and mixing

Download Cement Plant Operations Handbook For Dry Process ...

Download Cement Plant Operations Handbook For Dry Process Plants. Type: PDF. Date: November 2019. Size: Author: Nael. This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form.

Energy Consumption Benchmark Guide: Cement Clinker Production

Three dry process kilns have also been shut down during the decade, but average kiln capacity has increased by 34 percent, further contributing to gains in energy efficiency. Kiln Type Average Fuel Consumption (GJ/t) Total Energy Use 1990–1998 The next table shows total energy use, total clinker production and energy use per tonne of clinker. In comparing the average for the first three ...

dry process of manufacturing cement

dry process of manufacturing cement. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals. We can provide you the complete stone crushing and beneficiation also supply standalone crushers, mills and beneficiation .

Dry bulk freight rates continue to soar

· Dry bulk freight rates continue to soar. 13 October 2021. On 7 October 2021, the Baltic Dry Index, a global indior of bulk freight rates, reached 5670, marking its highest level since September 2008. This compares to just 393 in midMay 2020 at the height of the pandemic (see Figure 1). The surge in rates can be attributed to a number of ...

Dry Cement Process

Dry Cement Process. In dry process all the materials in powder form are ground separated in the absence of water and then mixed in the desired proportion and the resultant product is fed into kiln for burning. this process results less consumption of energy. and low ...

cement dry process technology

manufacturing of cement dry process • Chalk is porous and often has high moisture content that leads it to its use in the 'semidry/wet' manufacturing process of making cement This particular process represents some 16% of total production Shale • Shale is a pure sedimentary rock made of very fine silt clay and quarz Shale falls in the egory of mudstones Aug 23 2017The dry process of ...

Cement plant operations handbook : for dry process plants ...

Get this from a library! Cement plant operations handbook : for dry process plants. [Philip A Alsop; James W Post]

Cement Plant Power Solutions | GE Gas Power

Cement production is an energyintensive process, but the industry has boosted efficiency in recent years by investing in power plants that use the dry process of cement manufacture and phasing out more energyintensive wet process operations. Even using the dry process, the energy input needed to make one ton of cement is equal to about 389 pounds of coal.

Cement Manufacturing Process: What is Cement made of.

Dry Process of Manufacture of Cement. Following are the main steps in this process of cement manufacturing: i. Treatment Of Raw Materials. ii. Burning of the Dry Mix. iii. Grinding of the Clinker. iv. Packaging and Storage. You'll know all the process below in details. (i) Treatment of Raw Materials: The raw materials (limestone and clay) are subjected to such processes as, crushing, drying ...

clinker grinding mini cement packing plant in india

Cost Of Dry Process Cement Grinding And Packing Plant. Cost of cement clinker grinding machine dry process low cost cement clinker grinding plant view dry process low cost cement clinker grinding plantus 1000 99999 set new based on types henan china mainlandsource from henan mining machinery get price. Read More... Cement Plants – STRUCON Consulting. Civil Structural Design Detailing .

dry process cement production line

Leading Supplier of Cement Plant Equipments Rotary Kiln . The Production method usually adopts advanced dry process cement production technology. independent production, independent development, manufacturing, installation and commissioning, product sales and technical services with an annual production capacity of 100,000 tons.

The Cement Manufacturing Process

· Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln. In this process, the chemical bonds of the raw materials are broken down and then they are recombined into new compounds. The result is .

And Dry Processe Of Cement Manufacture

Aug 17, primarily for decorative purposes. portland cement manufacturing plants are part of hydraulic cement manufacturing, which also includes natural, masonry, and pozzolanic cement. the sixdigit source classifiion code (scc) for portland cement plants with wet process kilns is 305006, and the sixdigit scc for plants with dry process kilns is.

Latest Posts

- الفلسبار محطم كوريا

- مطحنة ريمون السعر المنخفض للبيع

- آلة غسل الرمل في المملكة المتحدة

- مصنع معالجة الذهب الانتعاش

- أجزاء من آلة كسارة المطرقة

- مصانع التصنيع في مصر

- بأسعار تنافسية كسارة فكية الحجر

- محطات كسارة الحجر في هيماتشال براديش

- الجزائر تستخدم سعر الكرة المطاحن

- عملية تعدين خام الكروم

- آلة محطم هيكل

- طحن معدات الاسمنت الصين

- الحجر الجيري المطرقة مطحنة في المملكة العربية السعودية

- تستخدم الحديد الموردين محطم خام في نيجيريا

- الأساليب قوات الدفاع الشعبي من تجميع فيروس مصنع

- Gold Planting System

- Quebec Stone Crusher Equipment For Sale

- Molino De Cebada Domestico

- Wet Stone Crusher

- Portable Concrete Batch Plants Cost Price In Nigeria

- Crushing Plant Uganda

- How Do You Mine Gold

- Tph Old Cone Crusher Plant Algeria Hyderabad

- Mobile Stone Crusher Equipment In Peru

- Ball Mill Dimentioon For T

- Animation Of Bowl Mill

- What Is Ag Grinding Wheel

- Stone Crusher Parts Manual

- Carbon Ferro Manganese Hammer Mill

- Sbm China In 43 Exhibition Algeria