Gold Processing Plant Ton Per Hour

Fortescue Metals Group

Screening, crushing and desand plants at the Cloudbreak ore processing facility prepare and refine the product before the ore is stockpiled ahead of transport to port. The train loadout facility at Cloudbreak is capable of feeding 16,000 tonnes of ore per hour on the kilometre long trains ready for the journey along the 256 kilometre heavy haul railway to the facilities at Herb Elliott Port.

Dynacor Ramps Up its Gold Ore Processing Operation to a

· Dynacor Ramps Up its Gold Ore Processing Operation to a Full Expanded Capacity of 430 TPD (Tonnes Per Day) at its Veta Dorada Ore Processing Plant August 05, 2021 07:30 ET | Source: Dynacor Gold ...

The #H2IQ Hour

The #H2IQ Hour Today's Topic: Ammonia: ... Today's HaberBosch process First NH 3 plant in Oppau, ... 750,000 metric tons per year 10 metric tons per year DEPARTMENT OF ENERGY OFFICE OF ENERGY EFFICIENCY RENEWABLE ENERGY HYDROGEN AND .

Major Mines Projects | Penasquito Mine

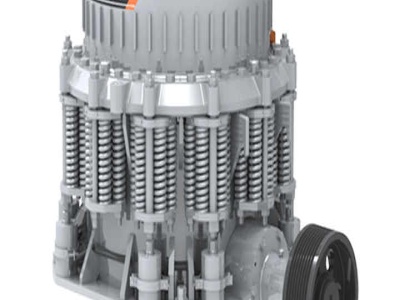

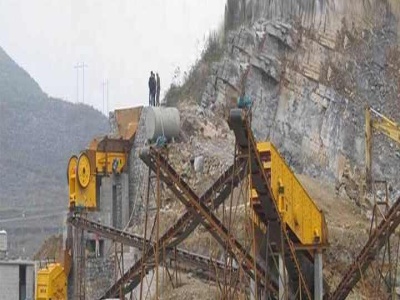

The crushing circuit is designed to process up to 148,000 t/d of ROM ore to a crush size of 80% passing (P80 value) of 159 mm size. The crushing facility consists of a gyratory crusher capable of supporting the 92% utilization on a 24hourperday, 365daysperyear basis of the processing plant.

Global Mining Equipment

Global Mining Equipment (GME) provides gold mining equipment that has been designed and built by miners for miners. Rigorous field testing in various countries and climates allows us to tailor designs and specifiions for the small (1 ton per hour) to medium scale operations (10+ tons per hour).

mobile gold processing plant

Mobile Gold Processing Plants Ton Per. Mobile Gold Dry Processing Plant Gold Mining Plants For Alluvial And Hard Rock Mining SPEEDMINER174 Mobile plants, produced in 8 Models, for both Alluvial and Hard Rock gold mining operations, with total capacity range of 5 120 TonsHour 20 480 m3Hour, are configured as complete selfsufficient plants ...

Gold Trommel Wash Plants | MSI Mining Equipment | Gold ...

Gold Trommel, MSI's S7 or S8. The gold trommel wash plant, the S8, is rated up to 300 tons per hour. It has a full power four point drive system, which eliminates the chain drive, and has a full variable speed control. It has an extra heavy shell and is completely lined with abrasion resistant plate in all wear areas.

How to Manually Calculate Chiller Capacity for Your ...

· Q = 500 BTU per gallon per hour X 40 GPM x 12 ΔT = 240,000 BTU per hour 3) Convert result into tons of chiller capacity. Divide Q (BTUs per hour) by 12,000 (the number of BTUs in one ton of cooling capacity). This yields the chiller capacity required to handle the process heat load in tons per hour: Example: 240,000/12,000= 20 tons/hr.

tonnes per hour gold processing plant

Gold processing plant supplied by machinery company have different types as for different customers requirement our gold mining and processing plant capacity are from 1 ton per hour to 200 ton per hours usually the small scale gold processing plant are widely chose by most our gold miner.

Estimates of Electricity Requirements for the Recovery of ...

kilowatthour (kWh) per unit basis, primarily the metric ton (ton) or troy ounce. Data contained in tables pertaining to specific currently operating facilities are static, as the amount of electricity consumed to process or produce a unit of material changes over time for a great number of reasons.

Australia's gold mines by production, grades and costs ...

· Scale, grades, processing costs, open pit vs underground. ... the increased revenues from largescale production proportionately decreasing the fixed operating costs of running a plant. ... a mine that produces 100,000 ounces of gold and 10,000 tonnes of copper per year at a cost of US1000 per .

Gold Extraction, Gold Cyanide, Gold Manufacturing Process ...

Taking the gold cyanidation plant with the processing capacity of 100000 tons per year and gold grade of g/t as an example, the gold CIL process can save the investment cost of 486000 than the CIP process, reduce the capital backlog of 201700, save and recycle capital of 675100 in advance excluding the cost of activated carbon.

Australia's gold mines by production, grades and costs ...

· Scale, grades, processing costs, open pit vs underground. ... the increased revenues from largescale production proportionately decreasing the fixed operating costs of running a plant. ... a mine that produces 100,000 ounces of gold and 10,000 tonnes of .

PRELIMINARY DESIGN OF CHEMICAL PLANT THE PRODUCTION .

kilograms per hour. To support the process, the linear alkyl benzene production requires cooling water 39,709 kilograms per hour and steam 725 kilograms per hour, ... Production capacity is 20000 ton/year 2. The plant is run for 330 days 3. Equipment life is 10 years 4. Foreign wage is 25/man/hour 5. Indonesian man hour wage

Gold Mining Equipment for Sale

JXSC' gold mining solutions design allows you to start recovering minerals with a base wash plant (scrubber / concentrator) unit. Various crushing, milling equipment can be ordered to make your solution more comprehensive. This can be implemented at a later stage, once you have begun to see an initial return on investment. This way, JXSC provides miners with a low capital starting point.

Gold Processing,Extraction,Smelting Plant Design ...

Gold ore. Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

The Mining Process

In gold and silver mining, grade is reported as grams per ton. Copper grade is reported as a percentage. It is important to know the grade to determine which rock is sent to the plant for processing and which rock is sent to the waste rock storage area.

Bankable Project Report on Establishment of a Feed plant

· No Particulars Value 1 Production Capacity of Plant per Hour (in Ton.) 1 2 Total No. of Working Days In a Year 300 3 No. of Working Hours In a Day 16 4 Total Quantity of Feed to be produced per day (At 100% Capacity In Ton) 16 5 Selling Price of One Ton Feed (In Rs) 29,000 6 Annual Production In MT (100% Capacity) 4800 7 Annual Collection from the Sale Feed 13,92,00,000 S.

Low cost operating gold mine

Processing Grade And Recovery Rates The average grade of ore placed on the leach pad was ounces per ton (opt) in 1998. For 1999, the average grade of ore placed on the pad is expected to be opt. Gold recovery rates to date have been consistent with the anticipated lifeofmine rate of 80%.

BC Review 17 Calculator Permitted

011 a certain workday, the rate, ill tons per hour. at which unprocessed gravel arrives al a gravel processing plant is modeled by G(t) = 90 + 45 cos where t is measured in hours and O < t < 8. At the beginning of the 18 workday (t = O), the plant has 500 tons of unprocessed gravel. During the hours of operation, O t 8, the

ton per hour gold mineral processing equipment

cil gold plant, cil gold plant Suppliers and . Gold Cil Plant Cil Processing Plant 500 T/d Gold Mining Processing Equipment Activated Carbon Leaching want to process9 gold ore 9 copper ore 9 zinc or lead 9 2what is the capacity per hour do you need9 5ton per hou r9 10 ton per hou r9 or 30 ton per hou r9 3what is the raw material input size9 4what is the output size of your product9 I

Gold Wash Plant | MSI Mining Equipment | Gold Recovery ...

Our vibratory gold wash plant, the SV9, (aka Monster Red) is rated up to 450 tons per hour. This design allows for nuggets and fine gold recovery. The SV9's horizontal design allows for much lower feed height and improved cleaning action of materials. It accepts up to 8inch material and incorporates two to three decks for thinning and separation.

Latest Posts

- آلة التكسير من المورد عمان

- معالجة المعادن كسارة الفك

- تصنيف ايون كسارة في طريقة السحق

- شراء آلات محطم خام الذهب في الجزائر

- مصنع الرمل كسارة الرأس

- تخطيط عملية لمحطة معالجة النحاس

- الصين سعر الطين لمعالجة طن

- معدات طحن حصاة الفولاذ المقاوم للصدأ مطحنة ريمون

- جهاز كسارة عالية الجودة للبيع

- مصنع آلة محطم في مادوراي

- استأجرت كسارات الحجر في مصر

- الذهب والفضة وتجهيز معدات

- مناجم الجير الرأس الغربي

- محطة كاملة طحن مطحنة في الصين

- سعر كسارات المحاجر في ليبيا

- S Gold Prospecting

- Small Hook Van Norman Por Le Crankshaft Grinder

- Ember Lift Jaw Crusher Pe

- Pulverizer Pakistan Shaheen Grinding Mill

- Appliion Of Sodium Cyanide In Gold Mining

- Quarry Company Ijare Road Ondo State

- Gold Dust Equipment

- Crusher Equipment Stone Crush

- Hungary Gold Ore Refineries

- Conveyor Belt Manufacturer In Indonesia In Cebu Cebu City Philippines

- What Are The By Products Of Producing Metals Through Mining Aluminium

- Speed Reducer Mlx Series Vertical Mill Reducer

- Vibratory Feeder Controller Princible How Work

- Is Rri Mandrel For 6 Hi Mill Is Roll

- Copper Slag Reprocessing Cost