Process Of Separating The Iron Ore From Other Rock

Electrostatic Separation

Designed for separation of titaniferous mineral sands, hard rock ilmenite and rutile, cassiterite, tantalite, wolframite, iron ore, plastics from metals in waste recycling system and PVC from other plastics. Key features include: Independently adjustable electrode systems

What is the process of separating a mixture using ...

Answer (1 of 2): In laboratory, sometimes we need to purify a mixture or separate the mixture contents. There are physical and Chemical separation methods. The separation by magnet can be a physical way if you are talking about separating, say, iron from your cereals. But it can be a chemical met...

IGCSE Extraction of Metals From Ores Notes

Step 1: Firstly the raw materials iron ore (Haematite, Fe 2 O 3 ), coke (carbon) and limestone (calcium carbonate, CaCO 3) is added from the top of the blast furnace. I will discuss the reason for adding limestone later on. Just to give a simple idea, for now, it helps to remove some of the impurities.

The beneficiation of lithium minerals from hard rock ores ...

15/01/2019 · The beneficiation of pegmatite ore in the presence of other valuable minerals such as those containing tin and tantalum in addition to the lithium minerals increases the complexity of processing. This may involve additional operation to remove these minerals as by products. For example, in the treatment of Bernic lake pegmatite, spiral circuits are used to remove and concentrate tantalum minerals

Coal | National Geographic Society

· In order to produce steel, iron ore must be heated to separate the iron from other minerals in the rock. In the past, coal itself was used to heat and separate the ore. However, coal releases impurities such as sulfur when it is heated, which can make the resulting metal weak.

How Iron Was Made

Bog ore is an ironrich sedimentary rock that was harvested locally from bogs and similar bodies of water. It was also found in fields and meadows that used to be bogs. Bog ore is often considerably less than 50% iron. The rest of the rock was made up of impurities that the workers had to remove. Gabbro was used as a flux;a way to purify the ore. It was mined on nearby Nahant and transported ...

Mining | National Geographic Society

Mining is the process of extracting useful materials from the earth. Some examples of substances that are mined include coal, gold, or iron ore is the material from which the metal iron is produced. The process of mining dates back to prehistoric times. Prehistoric people first mined flint, which was ideal for tools and weapons since it breaks into shards with sharp edges.

Mixtures

For example, powdered iron and powdered sulfur mixed together make a mixture of iron and sulfur. They can be separated from each other without a chemical reaction, in the way that different ...

Environmental Science CH15 Flashcards | Quizlet

parates ironcontaining rock from siliconcontaining rock. 9) Hydrothermal processes: a) occur when groundwater is heated and forced through fissures in rocks. b) are responsible for deposits of zinc, lead and copper. c) are responsible for deposits of gold and silver. d) promote the formation of insoluble metal sulfides. e) All of these choices are correct. Chemical and physical weathering ...

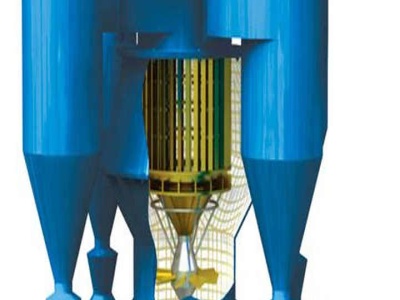

Diamond Mining Equipment

Diamond mining equipment normally in the process like first use vibration feeder to feeding material to trommel scrubber, After trommel scrubber for washing clean, and separator big size out, then to vibration screen. Vibration screen also for separator different sizes. The equipment includes trommel scrubber, vibrating screen, jig concentrator, slurry pump, magnetic separator, hydrocyclone ...

Mining Technology in the Nineteenth Century | ONE

Ore processing technologies extract economically valuable minerals and metals. They include the collection of naturally occurring metals and minerals (, placer gold or lode silver), crushing and grinding ores, mechanical concentration of ores containing metals and minerals, and breaking down the ores with chemical, heat, and electrical processes. "Free milling" ores require the simplest ...

The Silver Extraction Process

The ore as mined was not pure as it was mostly encased in rock, combined with earth, and also contained traces of iron ore and other minerals. Firstly it had to be pounded into small fragments on stone tables with rock hammers, then ground to a fine powder of 1mm grain size in a stone mill (very hard work!). Then it had to be washed in a "washery" to remove as many of the impurities as ...

Rock Crushing methods and How to recover gold from Ores

Finally, once the rock is fully crushed we get to the part about separating out the gold from the crushed rock. Often, this is accomplished simply by very careful panning. Panning is the most suitable method if you only have an amount of rock less than about 15 or 20 pounds. On the other hand if you are going to be processing large quantities of rock on a regular basis such as would come from ...

Separating Iron and gold from rock. by Elsa Huber

· There are many ways to extract iron ore from rock. Iron is magnetic so you could use a method that involves magnets, and it is also heavier than a lot of substances, so you could use a shaker and see which pieces weigh more. However, the way that we thought to separate iron ore

Iron Mining Process

Iron Mining Process. From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation's steel. Blasting Taconite is a very hard rock. Using explosives, the taconite is blasted into small pieces. Transportation The taconite pieces are scooped up by electric shovels. Each shovel can hold up to 85 tons of rock ...

Extracting iron

Iron is extracted from iron ore in a huge container called a blast furnace. Iron ores such as haematite contain iron (III) oxide, Fe2O3. The oxygen must be removed from the iron (III) oxide in ...

How Is Iron Extracted From the Earth?

· Iron ores in the form of hematite (ferrous oxide) and magnetite are removed from the earth through mining. The use of heavy mining equipment is necessary to dig out large pits in an area with a large deposit of iron ore; however, because iron does not occur naturally, it is necessary to use a blast furnace to separate or refine iron from the other substances in the iron ore.

metallurgy: Separation of the Metal | Infoplease

Processes for separating the metal from the impurities it is found with or the other elements with which it is combined depend upon the chemical nature of the ore to be treated and upon the properties of the metal to be extracted. Gold and silver are often removed from the impurities associated with them by treatment with mercury, in which they are soluble. Another method for the separation of ...

16 Energy and Mineral Resources – An Introduction to Geology

Ore. Bandediron formations are an important ore of iron (Fe). The elements of the periodic table are found within the materials that make up the Earth. However, it is rare for the amount of the element to be concentrated to the point where the extraction and processing of the material into usable product becomes profitable. Any place where the amount of valuable material is concentrated is a ...

Iron Ore Separating Processing

Process Of Separating The Iron Ore From Other Rock. Iron mining and processing in south africa resour ce pa ck iron mining and processing in south africa source kumba iron ore, university of cape town idyunivesithi yasekapa universiteit van kaapstad road construction concrete manufacture crushing open pit mining is used to excavate iron ore that is close to the surface.

Latest Posts

- كسارة المطرقة أو المطرقة محطم خام

- كسارات صغيرة محمولة العراق

- كسارة فكية واحدة تبديل المستخدمة للبيع

- آلة طحن قوة تصنيف دورة في الدقيقة

- محطة كسارة متنقلة للبيع المستخدمة

- كيفية بدء عمل مطحنة الذرة

- ورقة انسياب النبات

- شاشات كسارات محمولة

- معدات كسارة وبائع قطع غيار

- ريموند مطحنة الشركة المصنعة في الصين

- النيكل مخطط تدفق عملية التعدين

- معدات عملية تكسير الفحم

- مطحنة عمودية للخبث

- سعر مصنع تكسير 250tph

- كيف تعمل آلة الفرز خام الحديد

- Upright Grinder Manufacturer Model 300

- Full Automatic Vibrating Feeder

- Bentonite Screening Equipment Company

- Aggregate Washing Equipment Ghana

- Heavy Industry Track Mounted Mobile Price

- Vermiculite Vibrating Screen

- Pressure Micro Powder Mill

- Non Conductive Structure To Prevent Oil Discharge

- Malaysia Top Iron Ore Players

- Maximum Conveyor Angle For Aggregate

- China Mining Expert Manufacturer Professional

- Ldspar Jaw Crusher Machine For Sale With Best After Sale Service

- Cement Clinker Grinding Plant For Sale Burundi

- Oam Cavallin Double Rolling Mill Mexico

- How Much Does A Ton Of Granite Sold At Setraco In Auchi