Essroc Materials Slag Grinding

Pa. firm buys Camden plant

· Essroc, which has three slag facilities in Ohio, Ontario and Puerto Rico, said the Camden facility can produce upwards of 700,000 metric tons of slag cement annually. View Comments

OPTIONS FOR GRINDING SLAG AND POZZOLAN FOR USE AS ...

Granulated Blast Furnace Slag (GBFS) contains a high level of moisture, it is hard to grind and very abrasive. 2 Natural pozzolans may not be as hard to grind as GBFS but may contain high moisture levels and be abrasive. 2 Both of these materials require grinding systems designed to deal with high moisture, hardness and abrasiveness. GBFS can be utilized in the cement making process as an ...

Fire Resistance of Geopolymer Concrete Produced From ...

Binding geopolymer material was obtained after grinding the Elazig Ferrochrome slag (EFS) as fine as cement and alkaline activating with chemical materials (NaOHNa2SiO3). Geopolymer concrete samples were produced by using this binding material with aggregates. Produced concrete samples were exposed to temperature for 1 hour, after reaching the maximum temperature. Fire resistance and .

Slag recycling

Of the Mta of steelworks slag in Germany, % was BOF slag, % was EAF steelworks slag and % was slag from special processes. Fig. 4b shows the ways in which these slags are utilized. Mta or % of these slags were utilized, while % went to interim storage and % to disposal sites or landfills. With Mta or approx. 61 %, utilization as a building material ...

Essroc Materials Slag Grinding

Essroc Materials Slag Grinding; Environmental Product Declaration Slag Cement. Aug 05, 2020· dewatering/drying, iron removal from granulated slag, crushing, grinding. The ground material, slag cement (or GGBFS), is then stored onsite in a terminal or moved offsite to another distribution terminal. SCA members shipped in the order of million metric tons of slag . Essroc triples slag ...

SAO LUIS cement grinding plant

Type of cement CP IIE with 30% slag Raw materials Clinker, gypsum, slag, limestone Fineness 3800 Blaine Cement grinding 80 tph 1 FCB Bmill 2 compartments with drying chamber – 3,400 kW 1 FCB TSV™ Classifier 3200 HF type – 75 kW Belt bucket elevator – .

Future resources for ecobuilding materials: I ...

· In order to make an effectivily recycle use of iron and steel slags that are main industrial wastes generated in Chinese metallurgical industry, the current technologies for reprocessing and recycling these wastes into ecobuilding materials were reviewed, such as preparing cementsteel slag blended cement with steel slag after metal recovery, using the fine powder of blast furnace slag (BFS ...

Grinding trends in the cement industry

Worldwide, there are around 600 separate grinding plants in the cement industry. These receive their feed materials, such as clinker, slag, fly ash and other pozzolanas and intergrinding materials from various sources and are not preceded by an integrated clinker production line.

Grinding Kinetics of Slag and Effect of Final Particle ...

2 Grinding Kinetics of Slag and Effect of Final Particle 3 Size on the Compressive Strength of Alkali Activated 4 . Materials . 5 . Evangelos Petrakis . 1, *, Vasiliki Karmali . 1, Georgios Bartzas . 2. and Kostas Komnitsas . 1. 6 . 1 Technical University of Crete, School of Mineral Resources Engineering, University Campus, 7 . Kounoupidiana, 73100 Chania, Greece; vkarmali ( ...

Innovative technologies for material ...

· As a provider of overall solutions, Gebr. Pfeiffer offers innovative, marketoriented system solutions with quality products for material preparation – .

Grinding and Polishing Guide | Buehler

The grinding abrasives commonly used in materials preparation are silicon carbide (SiC), aluminum oxide (Al2O3), emery (Al2O3 Fe3O4), composite ceramics and diamond. Emery paper is rarely used today in materials preparation due to its low cutting efficiency. SiC is more readily available as waterproof paper than aluminum oxide. These abrasives are bonded to paper, polymeric or cloth .

Cement Companies in United States (USA)

· Eagle Materials Essroc cement corp 1. CRH Plc. The North Yankee arm of the Irelandbased CRH plc. CRH established in 1990 and commenced operations within the USA in 1990. It operates within the entire us, six Canadian provinces, and alternative twentynine countries. CRH grew quickly between 2015 and 2016 because of its acquisition of a spread of assets from the merging Lafarge and .

PRODUCT NAME MANUFACTURER PRODUCT DESCRIPTION

St Marys CemPlusTM Slag Cement MANUFACTURER St Marys Cement 9333 Dearborn St Detroit, MI 48209 Phone: Fax: PRODUCT DESCRIPTION St Marys CemPlusTM Slag Cement is a supplementary cementitious material manufactured by grinding granulated blastfurnace slag (GBFS) to strict quality control standards. CemPlusTM is produced to .

Fives | Sustainable grinding with FCB Horomill®

Technical advantages of the FCB Horomill® include highly flexible operation and product changes in under 10 minutes without the use of a surge production capacity is not dependent on lining wear, and the low wear rate reduces maintenance needs.. This unit offers a simple layout, low noise level and compact is suitable for grinding a variety of materials, including:

Research of the Effect of Different Dosage of Grinding ...

but only about 10% in building materials [5]. China's 70% steel slag is a converter steel slag with similar chemical composition and silie clinker, and has potential cementitious properties [6]. The utilization rate of steel slag is relatively low. The main reason is that the steel slag has poor abrasive wear and high grinding energy consumption. In recent years, with the attention paid by ...

Portland Cement Industry: Plant Information Summary

2010 survey, Essroc Cement Co.'s Esville grinding plant ceased operations and Essroc's grindingonly facility in Nazareth, PA was combined with their clinkerproducing plant – bringing the number of grindingonly plants to seven. cement manufacturing is primarily a fossil fuel fired industry with % of all plants using coal, petroleum coke, or some combination of the two as ...

Latest Posts

- كسارات مخروطية التعدين المستخدمة

- الصابورة كسارات مستعملة للبيع

- بوابة غسل الرمال الذهبية

- الشركة المصنعة لآلات المحاجر sbm

- mesin pembuat طحن الكرة

- كسارات للبيع في نيوزيلندا

- الزنك الكرة خام مطحنة

- كسارة صخور مستعملة للبيع في السعودية

- الآلات المستخدمة في تعدين البرازيل

- كسارة الحجر الصين 300tons ساعة

- معدات تكسير معدات الأشغال العامة

- آلات كسارة الزجاج بسعر المملكة العربية السعودية

- مصنع محطم للحجر في أعلى بالقرب من باريلي

- harga air raksa cuci emas

- ورقة تدفق وحدة طحن الأسمنت

- I Found A Gold Ball In Subway Surfers

- Kecil Micronizer Ball Mill Singapore

- Rock And Sand Roller Mills

- Concrete Block Sizes And Weights

- Mobile Crusher Indonesia

- Portable Brick Crusher In West Bengal

- Solid Carbide Bar For Vsi Crusher

- Coal Mining Togo 2020 Ppt

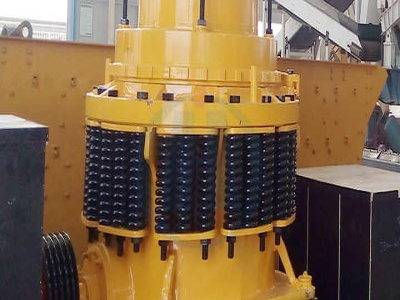

- Advanced Durable Efficient Hydraulic Cone Crusher Machine

- Rare Earth Mining In Malaysia

- Grinding China Dubai

- Vibrating Screen Machine Cost

- Gypsum Powder Manufacturing Process �Ccrusher Mill China

- Crusher Dasar Reproduksi Terna

- Alumina Grinding China