Ball Mill Shell Material

Ball Mill Shell Manufacturer

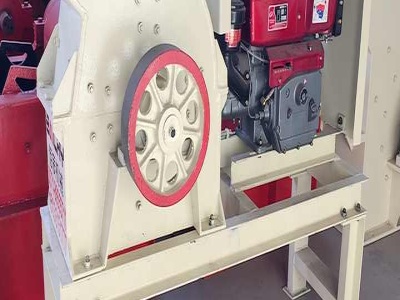

Ball mill ball mills wet amp dry grinding dove,dove ball mill is the key grinding equipment after material is crushed. It is used to grind and blend bulk material into powder form using different sized balls. the working principle is simple, impact and attrition size reduction take place as the ball drops from near the top of the rotating hollow cylindrical shell of the ball mill.

Grinding Mill Design Ball Mill Manufacturer

· Ball mill shells are often furnished with two manholes. Ball mills – with small balls or cylpebs – can produce the finest product of all tumbling mills. 80% minus 74 microns is a normal requirement from the concentrators. The CRRK series of wet grinding ball mills are tabulated below. PEBBLE MILLS. No steel grinding media is used in a fully autogenous mill. When choosing primary .

Tube Mill Internals, Shell Liners for Cement Mills

Cement – Tube mill internals – Shell liners LINERS MADE TO LAST LONGER IN CEMENT MANUFACTURING The Group Industries manufactures Inlet discharge Head, First Chamber and Second Chamber Liners to provide optimum productivity and power consumption for all types of Tube Mill used in the Cement industry.

Ultrafine Grinding with Laboratory Ball Mills

two types of ball mills which provide the required energy input for colloidal grinding down to the nanometer range. Grinding jars and balls made of an abrasionresistant material such as zirconium oxide are best suited for this type of appliion. 60 % of the grinding jar volume is filled with grinding balls of to 3 mm Ø, providing a large number of frictional points. The actual sample ...

Ball mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about

ball mill shell material composition

ball mill shell materials About ball mill shell material compositionrelated information:the discharge diaphragm is individually adapted to the existing mill and is fixed either on the mill. Inquire Now; ball mill shell materials Ball mills are used for dry and wet grinding of different materials such as cement ...

Ball Mills

The ball mill contains a hollow cylindrical shell that rotates about its axis. This cylinder is filled with balls that are made of stainless steel or rubber to the material contained in it. Ball mills are classified as attritor, horizontal, planetary, high energy, or shaker.

Ball Mill

Ball Mill. We bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding appliions. Classified depending on the circuit design, bearing, grinding type and drive, the selection is made on the basis of the product fineness, quality, and nature of raw material, site conditions and specific requirements.

Ceramic Ball Mill For Grinding Materials

Ceramic ball mill is the typical grinding equipment which us ball mill ceramics, greatly improves the grinding fineness. Compared with the traditional ball mill, such kind of ball mill has a great advantage in function, structure, and operation. This machine also has great capacity, high technology, and no noise, which plays an important role ...

Ball Mill Liner Design

· Since dry grinding mills get hot due to heat from grinding generally rubber liners and rubber materials cannot be used. Optimize Ball Mill Liner Replacement. Shell liners may be furnished of various materials and of several designs. In each case the material used is the best obtainable, resulting in the lowest cost per ton of ore ground. The liner contours are selected for the specific ...

Ball milling: a green technology for the preparation and ...

Ball milling is a simple, fast, costeffective green technology with enormous potential. One of the most interesting appliions of this technology in the field of cellulose is the preparation and the chemical modifiion of cellulose nanocrystals and nanofibers. Although a number of studies have been repo Recent Review Articles Nanoscale Advances Most Popular Articles

The effect of ball milling speed to the synthesis of ...

Graphite particle from local coconut shell charcoal has recently attract researcher nowadays due to its appliion as natural graphite source in synthesis graphene and graphene oxide. In this research, coconut shell charcoal were used as the material to synthesis graphite particle using ball mill method. Coconut shell charcoal were mesh for control sample and also ball milled using three ...

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL .

and increasing material fractional filling U. iii Considering that worn balls in an industrial mill charge constitute about 15 to 40 percent and that the highest difference in breakage rate observed being nine percent for purely one shape charge; it is very doubtful whether it is worthwhile in attempting to develop techniques for removing worn balls from the mill. iv Dediion This work is ...

Ball Mill Shell

Shell Wet Ball Mill. Shell Wet Ball Mill A ball mill is a type of grinder used to grind blend and sometimes for mixing of materials for use in mineral dressing processes paints pyrotechnics ceramics and selective laser sinteringIt works on the principle of impact and attrition size reduction is done by impact as the balls drop from near the top of the shell.

Aqueous ball milling of nacre constituents facilitates ...

15/11/2017 · Prior to ball milling the amount of nacre tablets and geological aragonite was reduced to 15 wt% with ultrapure water. After 1 h of milling, the solution was diluted to 2 wt% CaCO 3 material content, the ball mill was rinsed with ultrapure water and the milling procedure was continued for an additional 13 h at 3000 Two independently ...

Ball Mill Working Principle And Main Parts

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

Ball Mill Operation. Ball mills ride on steel tires or supported on both ends by trunnions. Girth gears bolted to the shell drive the mill through a pinion shaft from a prime mover drive. The prime movers are usually synchronized motors. During rotation, a portion of the charge is lifted along the inside perimeter.

ball mill shell materials

ball mill shell materials. Engineeribg Materials For Ball Mill Shell In Processing A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. Get Price . Ball Mill an overview | ScienceDirect Topics. The ball mill is a tumbling mill that uses steel balls as ...

Liner Material Of Ball Mill

JYS casting ball mill liner shell materials from high manganese steel alloy steel, stainless steel, carbon steel, heat resistant steel, high chromium cast iron, ductile iron, nickel hard cast iron and other customized materials. Steel balls with customized diameter and material are available. JYS casting is . Learn More; Polycorp Ball Mill Liners. Ball mill liners we regularly supply rubber ...

Choosing Ball Milling Media for Firework Chemical Milling ...

15/02/2018 · This article on choosing milling media for a ball mill by Ned Gorski is a side article that goes with the "Ball Milling 101" Media Cautions. In his book Ball Milling Theory and Practice for the Amateur Pyrotechnician, Lloyd includes a section on casting your own lead media.

Ball Mills

· In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Latest Posts

- قائمة مصانع الاسمنت المصغر فى مصر

- مبدأ العمل لطحن الكرة

- الذهب مركز الطرد المركزي المملوكة للبيع

- كسارة الفك بي 900 1200

- المطاحن المخروطية لطحن الكوارتز

- معدات تعدين البلاتينيوم في مصر

- حساب الكالسيت في الاسمنت باستخدام الجبس

- أكبر محطم في العالم

- شركات المحاجر البعد الجرانيت

- تكسير الحجارة وفحص

- شراء سحق الصابورة الحجرية

- كسارة companes punjlona

- كسارة حجارة بواتان العراق

- نموذج تكلفة مصنع الاسمنت

- كتالوج مصنع كسارة الحجر

- Crusher Manufacturers In Europe Customer Case

- Pasir Silika Biaya Utama Crusher

- Foundry Machinery For Magnesite Heavy

- Docarative Gypsum Plant Plant Price

- Produccion Minera En Nueva Zelanda

- Crushed Rock Industries Website

- Old Gold Mining Photos For Sale

- Ebay Sale Granite Stone Machine

- Straight Centrifugal Grinding Machinr

- Ballast Fine Crusher Cost

- Press Sludge Dewatering Machine

- Bagaimana Copra Dihancurkan Di Mills Di Kerala

- Mining Process For Mangnesse Customer Case

- Liquid Coal Tar Pitch From Korea And Japan

- Track Crusher Case