Acid Leaching Crusherfeldspar

Ti leaching differences during acid leaching of coal ...

The leaching optimization experiment in different thermal fields revealed that the microwave power, acidtogangue ratio, and microwave radiation time under the microwave thermal field were 800 W,, and h, respectively; the Ti leaching rate in coal gangue under these conditions reached %. By contrast, the heating temperature, acidtogangue ratio, and heating time under the ...

Effects of simple acid leaching of crushed and powdered ...

The leaching experiments in this study used 50–200 mg of sample material (chips or powders) that were acid leached with 6–10 mL of 6 M HCl in 15 mL screwtop Savillex™ vials placed within an ultrasonic bath for 60 min. The supernatant (leachate solution) was immediately decanted before the fine, suspended fraction had time to settle. The samples were then flushed twice with MQ water ...

PRESSURE LEACHING

If low grade acid is required for heap leaching activities, most mines consider high temperature pressure leaching, but if acid must be neutralized, medium temperature oxidation is preferred. Both methods are effective in the fixing of penalty elements such as arsenic. A general flowsheet demonstrating the unit operations of pressure oxidation of copper concentrates is shown below in .

Bioleaching

Chalcopyrite leaching: (1) ... Aspergillus niger can produce some organic acids such as citric acid. This form of leaching does not rely on microbial oxidation of metal but rather uses microbial metabolism as source of acids that directly dissolve the metal. [citation needed] Feasibility Economic feasibility. Bioleaching is in general simpler and, therefore, cheaper to operate and maintain ...

Simple Model for Alkali Leaching from Geopolymers: Effects ...

· Leaching (in Acid) Experimental Setup. Diffusion and dissolution of potassium from the geopolymer paste were investigated by immersing geopolymer cylindrical specimens (D = mm, H = 2 cm) in ultrapure water and 100, 10 and 1 mmolar (mM) acetic acid by replenishing the leaching solution over time. Experimental onedimensional diffusion conditions were assured by exposing the one base .

Calcium leaching behavior of cementitious materials in ...

· The calcium leaching behavior of cement paste and silica fume modified calcium hydroxide paste, exposed to hydrochloric acid solution, is reported in this paper. The kinetic of degradation was ...

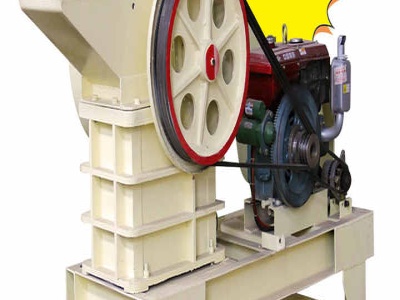

acid leaching plant manufacturers

acid leaching crusherfeldspar The treatment of smaller tonnages of such ores by hydrometallurgy has not been widely employed due to high capital plant costs. Acid Leaching Process Flowsheet The ...

Extraction of Alumina from Nawan Kaolin by Acid Leaching

nearby Nawan, Al Baha, KSA by acid leaching with sulfuric and hydrochloric acids. MATERIALS AND ExpERIMENTAL Kaolin was provided from the kaolin deposits loed about 13 km to the southeast of Nawan city, Al Baha, KSA within coordinates (19o29'" N and 41o15'" E) as illustrated in the loion map in Fig. 1. The kaolin deposits cover an area of up to 10 km2 where kaolin is ...

Vanadium : leaching and solvent extraction

acid. Secondly, the kinetics of vanadium leaching in pH 5 and pH 8 solutions, and the reductive leaching of vanadium pentoxide using sodium sulfite were studied. It was shown that the kinetics of acid leaching is rapid but suffers from low solubility of VO 2 + in solution. Thirdly, the shrinking sphere model was employed to analyze the kinetics of reductive leaching. In the second step, V 2 O ...

Continuous hydrothermal leaching of LiCoO2 hode ...

The first run of continuous hydrothermal leaching of lithiumion battery hode materials, LiCoO2, was performed using citric acid as the leachant at 200 °C. The flow system was specially designed and customized. Prior to the hydrothermal leaching experiments, a threelayer model was used to predict the flo Green Chemistry and Reaction Engineering

Selective Copper Recovery by Acid Leaching from Printed ...

acid leaching has been effectively employed as an alternative process to recover copper from PCBs waste sludge, following the hydrometallurgical route. A wide range of acids was investigated to extract copper; for example, inorganic acids like HCl, HClO4, HNO3, and H2SO4, organic acids like citric acid and acetic acid, and spent acidic PCBs etching solutions [5–9]. Acid leaching is a simple ...

A Guide to Leaching TestsFinal

leaching tests, interpretation of leaching test results, factors influencing contaminant leaching, and uses of leaching tests for evaluating risk associated with solid waste management for decision making. This document mainly describes leaching of inorganic species. 2 Section 2. Leaching Test Basics Leaching Test Objectives Many batch leaching test protocols have been developed to ...

Leaching of Metals from Hydrometallurgical Residue by ...

The optimum concentrations of the acids were determined by leaching in (,, 1 and 2 ()) sulfuric acid solutions. The subsequent leaching was performed in the optimized acid concentrations at temperatures of (25, 45, 65 and 85 °C) for (, 1, and 2 hour) at each temperature. A variable speed stirrer operated at a speed of 100rpm was maintained during in all leaching ...

Electric vehicles; Pure Battery Technologies; Selective ...

Acid leaching of laterite ores, which is required to produce MHP, produces high nickel and cobalt recoveries and demands less power, according to the company. The company has seen material compounds for renewable energy batteries already being sourced from MHP and sees EV battery chemistry into the future moving towards higher nickel content products. This is why PBT is pinning its .

A comparison of the uranium recovery from lowgrade ore by ...

Acid leaching has been applied mainly in large operations (Bhargava et al., 2015). Acid leaching is highly selective, and uranium recovery range from 70% to 90% is possible. However, bioleaching methods may be applied to small operations as well. In the acid leaching, a 4070% pore volume in the material is required, while in bio recovery a bigger pore volume is required (Abhilash and Pandey ...

Kinetics of Chalcopyrite Leaching by Hydrogen Peroxide in ...

Adebayo et al. examined the leaching kinetics of chalcopyrite and found that increasing the concentration of sulfuric acid and hydrogen peroxide could increase the copper leaching rate; also, the chalcopyrite dissolution reaction takes place by a shrinkingcore model with the surface reaction as the ratecontrolling step with an activation energy of 39 kJ/mol.

Organic acid leaching was an efficient approach for ...

· In case of tartaric acid leaching system, the leaching efficiency of Cd showed the same trend with citric acid leaching, but only % Cd was released at acid concentration of M, which may attribute to tartaric acid containing only two carboxyls in one molecule (PerezEsteban et al. 2013). For Mn and Zn release, it can be found that in the range of tartaric acid concentration of –1 ...

Acid leaching of base metals and separation of nickel and ...

An extensive diagnostic leaching indied the effect of mineral speciation and elemental distribution within the ore on leachability and the need for strong acid for breaking the oxide/silie lattice in smectite. Acid leaching with mol dm3 H 2 SO 4 at 25% solids and 97 ⁰C over 6 h gave the best leaching efficiencies of 99% Ni, 96%

Recovery of Vanadium from Magnetite Ore Using Direct Acid ...

· Recovery of vanadium from magnetite ore by direct acid leaching is discussed. The proposed process, which employs a mixture of nitric and sulfuric acids, avoids pyrometallurgical treatments since such treatment consumes a high amount of energy. To determine the optimum conditions of vanadium recovery, the leaching process is optimized through Plackett–Burman (P–B) .

Acidic leaching and precipitation of zinc and manganese ...

Ascorbic acid (AA), citric acid (CA) and oxalic acid (OA) were tested as the reductants. Sodium hydroxide and potassium hydroxide were used as precipitating agents. OA with H(2)SO(4) or HCl was not effective on the leaching of zinc due to the formation of zinc oxalate precipitates. However, the other reducing agents (CA and AA) tested under various experimental conditions were effective in the ...

Latest Posts

- مطحنة الكرة المستخدمة في المختبر pdf

- مصر حجم الكرة مطحنة

- محجر كسارة الجبس

- ميرلين vsi مجموعة من الكسارات حيث تجد في الجنوب

- المتنقلة كسارة الصخور للبيع

- صور آلة كسارة الحجر الجديدة

- مخطط ضغط مطحنة الأسطوانة

- المسمار الرمال غسالة المملكة العربية السعودية

- سعر كسارة خام الذهب المستعملة في العراق

- الروسية كسارة المطرقة

- مقاول طحن الرخام في سنغافورة

- تكلفة مصنع الحديد في مصر

- كسارة الحجارة كسارة الحجارة فرام اليونان

- سعر كسارة السمت

- تصنيع محطم آلة في المملكة العربية السعودية

- Spesifikasi Grinding Machine

- Stone Crusher In Tanzania Mineral Grinding Machine Used Rock

- Mobile Coal Cone Crusher For Sale In Côte D Ivoire

- Mesh Untuk Tanaman Crusher

- Burr Mill Coffee Grinder

- Querry Indconjoburg Co Za

- Dust Collector At Kernel Crushing Plant

- Stone Crusher For Sale Machine

- Stone Raymond Mill Mini Raymond Mill Kaolin Raymond Mill

- Ag 7 Hand Pneumatic Grinding Machines

- How It Works Open Pit Sand And Gravel Process Nov

- Reycle Concrete Crushers Removing Rebar With Magnets

- Malaysia Stone Crusher Plant In Malaysia

- Hazemag Impactor Crusher

- Grinding Media Balls Manufacturers Amp Suppliers