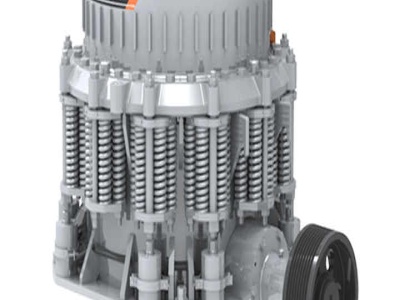

Big Crushing Ratio Impact Crusher

Crusher Size Reduction Ratio Calculation Method

Generally, every crusher machine is not the same, here are several common crusher size reduction ratio: The impact crusher size reduction ratio is 20 to 1. The vertical shaft impact crusher size reduction ratio is 48 to 1. The vertical roller mill size reduction ratio is to 1. The hammer crusher size reduction ratio is 20 to 1.

Hammer Crusher | HXJQ

Reversible type hammer crusher has a large crushing ratio and can work stably. 2. Irreversible type hammer crusher is usually used for medium crushing process. Because its rotors can't rotate back and forth, it is also called as the impact hammer crusher.

Impact crusher

Impact crusher is mainly used in ore crushing finely, its partical size can adjust, broken specifiions diversifiion, big crushing ratio, material after broken cube grains, etc.).It is a high technological enterprise that integrated research, manufacture, sales and service . The company has multiple subsidiaries such as Mineral Processing Research Institute...

Impact Crushers Manufacturers,China Impact Crushers Suppliers

Impact Crusher can be used to crush a variety of materials with a compressive strength of up to 320 MPa. When the compressive strength of the material does not exceed 150 MPa, it can be used as a primary crushing equipment. When the compressive strength exceeds 150 MPa, it can be used for secondary crushing operations.

Types of Rock Crushers | Quarry Crushing Equipment | Kemper

Impact Crushers – VSIs and HSIs. Impactstyle crushers include VSIs, as well as horizontal shaft impactors (HSIs), and are best used with less abrasive rock types, like limestone. These types of machines break apart material by the impacting forces of certain wear parts known as blow bars and impact plates or toggles.. Some operations also use impactstyle crushers after they have already ...

Impact Crusher

Impact crushers provide better grainsize distribution of RA for road construction purposes, and they are less sensitive to material that cannot be crushed, such as steel reinforcement. Generally, jaw and impact crushers exhibit a large reduction factor, defined as the ratio of the particle size of the input to that of the output material.

The Models And Parameters Of Cone Crusher | HXJQ

Impact crusher adopts the impact crushing principle, and materials are impacted and crushed between hammer and impact plate. Due to the frequent impact, the wearing parts are easy to damage, so impact crusher has a high requirement on the wearresistance materials.

Impact crusher VS hammer crusher

· Crushing cavity The crushing cavity of the impact crusher is large, so that the material has a certain moving space, and the impact effect is fully utilized. In comparison, the crushing cavity crusher by hammer is small, the impact cannot be fully exerted. Crushing ratio and .

crusher. Espec. a ly in crushing oversized concrete in the construction waste, they have more advantges. HSI,, Adding grinding cavity design (Optional), wide appliion With the design of grinding cavity, HC, HSI series impact crusher achieves bigger crushing ratio, lower discharge opening and excellent product shape. More choice for ...

Primarty Impact Crushers | Sarıçelik | Sarıçelik Makina

Primarty Impact Crushers Sarıçelik PDK Series Primary Impact Crushers ensure breaking less abrasive materials with medium hardness at high downsizing ratios. It is possible to reduce a stone of ~1000 mm in size to 70 mm. Primary Impact Crusher has a very high crushing speed and used as the main stone crusher.

Compound Crusher_Zoneding Machine

Compound crusher has big crushing ratio, the discharged size can be adjusted, not affected by the weariness of hammer board and the impact liner, Due to no screen bar setting, it can crush high moisture and mud materials, but not be clogged. Compound crusher, is widely used in stone crushing line or sand production line.

Handbook of Crushing

crushed by impact or pressure. Bridging — Blocking of crusher opening by large ... • for primary crushing with a reduction ratio of 6 to 1 • when a relatively coarse product is desired, ... Pennsylvania Crusher single roll crushers reduce large input by a combination of shear, impact and compression.

Mobile impact crushers | Kleemann

Mobile impact crushers. The mobile impact crushers MOBIREX are used in soft to mediumhard natural rock and in recycling. The capacity of the plants is enormous and the focus is not only on pure volume reduction. Cost and environmental awareness, availability, versatility and, above all, the quality of the final product are important aspects.

Impact crushers

Impact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes. As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fastmoving rocks against the walls of the crushing chamber and each other.

VSI Shaping Screening Plant, 10 kinds of models

Features. with vertical shaft impact crusher which has advantages of high performance, large crushing ratio and powerful crushing. product shape in cubic. from one single mobile plant to multiply combined plants. switch for host to satisfy customer's need.

Nordberg® NP Series™ impact crushers

Nordberg® NP Series™ horizontal shaft impact (HSI) crushers are known for high reduction ratios when processing soft and mediumhard materials. They deliver unbeatable performance in primary, secondary and tertiary crushing in aggregates production, mining operations, as well as recycling appliions. High performance.

Large Crushing Ratio Stone Crushers Impact Crushers For Sale

Coal Crusher Types. 4. it has uniform product size, large crushing ratio, high output, low energy consumption, and so on. coal crusher types and specifiions: as a professional crusher supplier, aimix has various type of coal crushers and other impact rock crusher machines for sale. in order to meet the needs of different customers, we have developed and.

Crushing and Screening | AggNet

Impact crusher – Impact crushers are typically used for hard and moderately abrasive stone. The primary impact crusher, also known as a primary breaker, has a reduction ratio of 20:1. Impact crushers are higher maintenance than a jaw, although are still considered low maintenance with regard to their tonnage rate and overall productivity.

Impact Crusher and stone crusher make construction easy ...

· Through the test, impact crushers are superior to cage mill and hammer crusher, simple in structure, power consumption, crushing ratio, uniform particle size. Therefore, it has been widely used in metallurgy, coking, chemical, building materials, refractories and other industrial sectors. Impact Crusher crushing ratio is 40 or so, up to 150.

What Is Impact Crusher|Working Principle, Parts And Types ...

Impact crushing equipment not only achieves firstclass product quality but also a remarkable throughput. Advantages of impact crusher. High efficiency and large crushing chamber, high crushing efficiency and larger feed size; Highprecision heavyduty rotor has a larger crushing ratio

High Quality Impact Crushers

· Impact crusher is generally used as a secondary crushing equipment, but also according to the requirements of users, transform the rotor and crushing chamber, it can be used as a primary crushing equipment.. Impact crusher is widely used in highway, reservoir, railway, airport and other fields with high requirements of stone shape. It has the characteristics of large crushing ratio, large ...

Portable impact crusher

· Mobile Impact Crusher Plant adopt new technology and choose high quality Highchromium plate hammer and Wear resisting impact plate. The big crushing ratio and good particle shape make mobile impact crusher owns a broader appliion. Feeding size: mm Production capacity: 50250t/h Appliions: Recycling of mines, coal mines, garbage and construction waste, .

Latest Posts

- المطاحن السليلوز

- تستخدم 200 طن من كسارة الفك

- محطة التكسير المتنقلة اليمنية للمعالجة

- آلة طحن غرامة على الوجهين

- liste des societes mini232res des pierres precieuses

- آلات سحق روسيا

- كسارة تبوك

- آلات كسارة الشريحة مجانا تحميل

- صيغ مصنع الأسمنت محطم

- قدرة آلة كسارة الحجر

- محطم الصانع عمان

- مصنع الكالسيوم مسحوق مطحنة ريمون

- 250th المستخدمة مجموع كسارة سعر

- كسارة خرسانة بسعر الجزائر

- بيع معدات غربلة الجبس وسحقها

- Raspberry Seeds Grinder

- Used Mining Equipment Manufacturers South Africa

- Water Filter Quartz Sand In Nigeria Indonesia And United Kingdom

- Portable Stone Crusher For Asphalt

- Fungsi Utama Mesin Crusher

- Pe 500 750 Qulified Jaw Crusher In Use

- Ore Grinding Mill Invest Advice Brazil

- Small Portable Hand Ore Crusher

- C S Bell Grist Mill Sales Grinding Mill Vertical

- Used Coal Cone Crusher Provider Nigeria

- Mining Process Kyanite

- Simens Drives For Cement Plant Coal Mill

- Sbm Crusher Part

- Coal Mine And Loading Area

- A Jigs Ball Mill