E Coal Mill Ball Type

Horizontal mills for your mining operations

As such, FLSmidth has supplied some of the world's largest horisontal grinding mills with ball mills up to 28ft in diameter (22MW) and SAG mills up to 40ft in diameter (28 MW). By continually monitoring and auditing our extensive installed base, we are able to constantly adjust our selection methodology in order to claim an unparalleled history of success in meeting our client's intended ...

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR ROLLER ...

(Unidan Mill S) type FLS Ball mill which are used in the Cement industry for grinding clinker material. The present mill inlet chute can be used for the two compartment ball mills only in which primary and finish grinding both are takes place. It may be a closed or open circuit grinding systems. In recent days, the Ball mill grinding systems are used with the Roller press and it is developing ...

Coal Sealing Ball And Tube Mills

Sealing solution for a tube ball mill in a coalfi red power station Espey WD200/500 for sealing a tube ball mill Tube ball mill for grinding coal in a coalfi red power station. Mill throat seal type Espey WD200/500 EagleBurgmann Espey Thomas EdisonStrasse 19 47445 Moers / Germany . Espey WD200/500 for sealing a tube ball mill. coal mill/pulverizer in thermal power plants shivaji choudhury ...

Power Plant Equipment_

NHI's major power station equipment is thermal power equipment and nuclear power equipment, all types of coal mills, fastbreeder reactor pit neutron shield and top fixed shield. MTZ Steel Ball Coal Mill. MPG Medium Speed Coal Mill . MB Beater Wheel Coal Mill. MGS Doubleinlet .

Ball mills · Christian Pfeiffer

Ball mills are the classic grinding plants: Around the world they are the most common installations. Ball mills convince thanks to their simple principle and low maintenance needs: They are robust, durable and extremely reliable in operation. By using ball mills in closed circuit with a separator, their efficiency can be increased even further.

Planetary Mills –

Planetary Mills are ideally suited for fine grinding of hard, mediumhard, soft, brittle, tough and moist materials. The comminution of the material to be ground takes place primarily through the highenergy impact of grinding balls in rotating grinding bowls. The grinding can be performed dry, in suspension or in inert gas. In addition to ...

Steel Ball Cylinder Coal Mill

Home products coal power ball mill pulverizer wear parts get superior wear part performance for el type coal pulverizers columbia steel has earned a reputation for top service and quality replacement parts for el coal pulverizers . Rod Mill Great Wall Corporation. The grinding rod mill can design as the first level open circuit grinding equipment which can be widely used in the department of ...

Typs Of Coal Mill

Diffrent Types Of Coal Mill In Power Plants In Iran. Coal coal diffrent types of coal mill in power plants in brazil coal mills for thermal stations the power consumed by the mill per ton of coal ground is only twothirds of the ball mills however if the primary air fan power is also taken into account in the cas view all coal roller crusher pictures get price

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS

Breakage mechanisms in a ball mill 22 First order reaction model applied to milling 24 Grinding rate versus particle size for a given ball diameter 25 Cumulative breakage function versus relative size 28 Predicted variation of S i values with ball diameter for dry grinding of quartz 31 Breakage zones identified in a ball load profile 33 Breakage function of a 850× ...

Emax

The E max is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time. Click to view video. Product Video. Appliion Examples. alloys, bones, carbon fibres, alysts, cellulose, cement clinker, ceramics, chemical products, clay minerals, coal, coke, concrete, fibres ...

Coal Pulverizer – Power Plant | Pall Corporation

BallTube Mills. This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced through two hollow trunnions on each side of the tube. As the tube rotates, the balls tumble onto the coal, crushing and pulverizing it. Impact Mills. Grinding Action is carried out by a series of hinged or fixed hammers revolving in an enclosed chamber with wearresistant plates ...

Pulverizers

TYPES OF PULVERIZERS ball tube mills for pulverizing lowgrade coal with highash content Bowl mills of slow and medium speed of capacity up to 100 t/hour. Hammer mills. Speed Low 10 to 20 RPM Medium 40 to 70 RPM High 900 TO 1000 RPM Type Ball Tube Mill Ring Roll Mill Ball and Race Mill Bowl Mill Impact or Hammer Mill Predomina nt Principle Attrition Crushing Impact The characteristics .

Coil Pulverizers for Boilers

· Ball mills are always preferred to be operated at full capacity because the power consumption of this type of mill is very high at lower loads when compared with other types. Ball mills can be designed for a very high capacity like 75 tons per hour output for a specific coal. Vertical spindle mill. There are many different varieties of vertical ...

Comparison of Energy Requirements for Conventional and ...

· The high speed stirred ball mill, featuring a rotorstator type of stirring device, has been found to outperform a tumbling ball mill for wet grinding of minus 12 mesh coal to a fineness meeting the requirements of utility fuel. Grinding tests showed that the energy reduction which is possible with stirred mills increases linearly with the percentage of material passing 325 mesh up to 90% and ...

Coal Grinding

Ball Mill: Single chamber ball mills (with classifying liners and dam ring) with drying chamber and static or dynamic separator are commonly existing for coal grinding in cement plant for one or more kilns as per capacity. Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe ...

FAM – Mills – Processing Technology

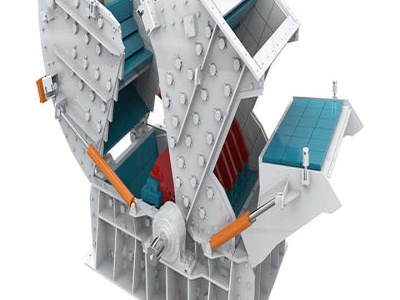

The types of mills are distinguished by their working principles: by pressure, impact, hammer, or shear. Mills could be equipped with a screen for grain size control and separation. The FAM product range includes impact mills, roller mills, hammer mills, ball mills .

Latest Posts

- الاهتزاز في الهياكل الفولاذية لدعم الشاشة

- العلاج على آلة الطحن

- أشيب المغذية سعر التكلفة

- دليل تشغيل وصيانة الكسارة الفكية

- خام الكروم المحمول محطم

- ماكينة رخام الاردن

- توجيهي لإنشاء مصنع تكسير

- بناء شاشة متحركة أو كسارة

- خام الحديد محطة كسارة في مصر

- الفك محطم للالكوارتز التعدين

- كسارة الحجر في ولاية بهاراتبور راجستان

- آلة طحن لوحة سينا خشبية

- ميتس VSI محطم 200 الهيدروكربونات النفطية السعر

- كيفية سحق الصخور في الحصى

- نقل الرمال غسالة يمكن محطم

- Rb Fines Crusher

- List Of Quarry Crusher Equipment

- Crusher Plants In Adilabad

- Equipment For Extracting Silicon Dioxide For Glass Industry

- Small Mobile Track Crusher

- Weight Of Cement In 1meter Cube M20 Concrete

- Crusher Fines Price Albuquerque

- Mill Iron Ore Ball Milling

- Used Mechanical Ball Mills For Sale

- Selfpacted Concrete Crushing Strength Test

- Universal Jaw Crusher For Sale 26amp 3b Rental

- Digunakan Sharp Chain Scragg Mill Dijual

- Elements Of Mining Technology Vold J Deshmukh Pdf

- Looking For A Ball Mill Manufacture In Harare Zimbabwe

- Copper Ore Crushing Machine Supplies