Cement Coal Crushed

Cement – FluiDimensions

Cement Production involves calcination of Raw meal generated by Coal or petcoke Combustion in Kiln and Calciner. The Conversion of raw meal to Clinker happens in "Pyro Section". Almost 60% of the Calcination of raw meal is completed in Calciner and the remaining in long, rotating, horizontal Kiln. The raw meal is preheated in a series of Preheated Cyclone before Calcination. The hot ...

An Experimental Study of the Road Performance of Cement ...

· PDF | The research into the road performance of coal gangue is of great significance for the consumption of coal gangue and reducing pollution. In this... | Find, read and cite all the research ...

Whatever You Need Weighed and Measured

What do you need weighed and measured? Crushed stone? We can do that. Ore? That too. Cement? Coal? Food? Chemicals? No problem. With SIEMENS fieldproven SIWAREX weighing electronics, SIWAREX load cells, conveyor belt scales, solids flow meters and weighfeeders, SIEMENS weighs your world with firstclass solutions that help you accomplish almost any weighing task.

Crushed Coal Exporter | FaNat

Description: We are traders of Indonesian coal and offer five main calorific values: ICI 1 GAR 6,500 / 6,200 NAR ICI 2 GAR 5,800 / 5,500 NAR ICI 3 GAR 5,000 / 4,600 NAR ICI 4 GAR 4,200 / 3,800 NAR ICI 5 GAR 3,400 / 3,000 NAR GAR (Gross As Received) thermal coal is quoted on a GAR basis and Japan / Korea / China which is quoted on a ...

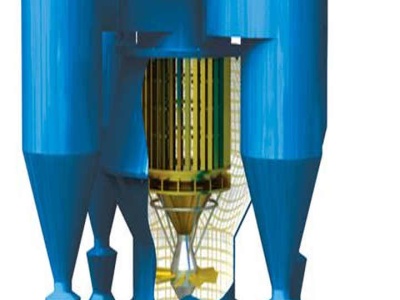

COAL GRINDING AND DRYING IN CEMENT INDUSTRY

The preparation of coal in cement works comprises the grinding and drying of raw coal delivered to the works. In cases where the coal consumption rates are high and coal from different sources are used, it is advantageous to blend the various coals in conjunction with stockpiling so as to obtain a fuel that is physically and chemically as closely uniform as possible and thus, to achieve well ...

Can I Use Crushed Cement That Is Gone Hard

Can I Use Crushed Cement That Is Gone Hard. It also had a couple of lesser known uses it was mixed with cement to make to as MOT even though the MOT Ministry of Transport disappeared in the s Generally hardcore is any hard crushed inert material that can be used as a Gravel driveways and crushed stone driveways can be seen all over the United States in the shortest amount of time with .

Hydraulic Roller Press in Cement Plants | AGICO Cement ...

The cement roller press is a type of material crushing machine which is often used in cement plants. It usually works together with a ball mill to form a pregrinding or finalgrinding system for the grinding of raw materials, coal, and clinker.. Compared with the traditional tube mill and ball mill, the roller press has lower energy consumption and higher production efficiency, and consumes ...

Cement

· This is sometimes done with rollers that crush the materials against a rotating platform 4. Grinding of Raw Materials Manufacturing of Cement (contd) 38. 45 Tube Mill The tube mills are used to have preliminary grinding of raw materials or mixture of raw materials or clinkers 39. 46 5. Sintering • Everything then goes into a huge, extremely hot rotating furnace to undergo a process called ...

Crushed into powder coal

How To Make Coal Into Powder. A cement mill is the equipment used to grind and margins of these plants decline quickly with import duties or the cost of grinding the clinker into cement15 clinker manufacturers cost clinker manufacturers cost grind it to make finished cement or clinker grinding plants that intergrind grinding machine used for convert coal into powder . Why Coal Is Crushed In ...

The Cement Manufacturing Process

Another important cement raw material is coal that acts as an energy source in the cement manufacturing process. For this purpose, the raw coal is also crushed and stocked in the longitudinal stockpiles and is taken out diagonally by the reclaimers before further grinding of fine coal. Jharkhand has the biggest coal mines in India followed by Orissa, Madhya Pradesh, Chhattisgarh, West Bengal ...

Our Products

More often than not, it is crushed and used in construction as part of cement. Other specialized uses include paving roads or used in agriculture to neutralize acidridden soil and as a filler ingredient in toothpaste. Powdered limestone is antipollution and acts as a sorbent to absorb pollutants in the air and crushed limestone is used as a natural filter in onsite sewage systems.

Replacement of Cement in Concrete

Replacement of Cement in Concrete P. Vipul Naidu1 and Pawan Kumar Pandey2 1CivilSOT, ... byproduct of the combustion of pulverized coal and is collected by mechanical and electrostatic separators from the fuel gases of thermal power plants, where coal is used as a fuel. Limestone (CaCO 3) is a raw material available in nature, it is primary need for production of cement material. Fly ash is ...

Rotor weighfeeder for dosing crushed coal I FLSmidth

Coal feeding needs to be safe and it needs to be efficient. The PFISTER® TRWK rotor weighfeeder ensures consistently accurate dosing of crushed coal to the mill in a safe, enclosed, pressureproof system. Advanced weighing electronics provide constant precision, whatever your feed characteristics.

Alternative Fuels in Cement Manufacturing | IntechOpen

· Alternative fuel options for the cement industry. Coal is the primary fuel burned in cement kilns, however, the use alternative fuels in cement kilns is now common and increasing. The range of alternative fuels is extremely wide. They are usually available as gas, liquid and solid as shown in Table 1. Before proceeding to a consideration of some of these fuels and their properties it is ...

IS 38122 (2033): Specifiion for Pulverized Fuel Ash ...

finalized by the Cement and Concrete Sectional Committee had been approved by the Civil Engineering Division Council. Pulverized fuel ash is a residue resulting from the combustion of ground or powdered or crushed bituminous coal or subbituminous coal (lignite). About 80 percent of the total ash is finely divided and get out of boiler along

Cement Industry

The cement industry is the third largest user of coal after the steel and power industries and it consumes more than 5% of total coal produced in India. This coal requirement will go up further with the rapid expansion of the cement industry (for infrastructure projects). Coal is the principal source of fuel for cement kilns. Its consumption per ton of clinker largely depends on the quality ...

Cement Extenders Mechanisms Chemistry

· Most extenders in this egory are inert with respect to the cement. Expanded perlite. Perlite is a crushed volcanic glass that expands when heated to the point of incipient fusion (Lea, 1971). The expanded perlite product generally has a bulk density of lbm/ft3, which allows the preparation of competent cement slurries with densities as low as lbm/gal [ g/cm3 ]. A small ...

cement coal crushed

cement coal crushed. cement coal crushed. Mass, Weight, Density or Specific Gravity of Bulk Materials. The mass of over 300 different 'dry' materials are listed below. Liquids, metals and woods are on other pages and a site search facility is on the home data is useful for the design and selection of bulk materials handling plant, bulk transport and . >Get Price; why is coal crushed ...

How Cement Is Made

The crushed rock is combined with other ingredients such as iron ore or fly ash and ground, mixed, and fed to a cement kiln. The cement kiln heats all the ingredients to about 2,700 degrees Fahrenheit in huge cylindrical steel rotary kilns lined with special firebrick. Kilns are frequently as much as 12 feet in diameter—large enough to ...

cement coal crushed

cement coal crushed .with sand,aggregate (small stones,crushed rock._ 2 : Modern cement,called Portland cement,was invented in 1824 is a mixture .(small stones,crushed rock,or gravel),and water to make

cement coal crushed

cement coal crushed Cement crusher, cement crushing machine used in cement CGM cement crusher used in cement production line, cement crushing machine is very important since most of ... >>GET MORE. How Cement Is Made. How cement is made and history of Portland Cement. Skip To ... The crushed rock is combined with ... produced by precisely controlled burning of powdered coal ...

cement coal crushed

cement coal crushed cement coal crushed. The Use of Crushed Limestone Dust in concrete. Crushed limestone dust is a waste material from the production of concrete aggregate by crushing quarried limestone rocks. The dust is usually less tan 1% of the aggregate production. Although it is coarser than common cementing materials such as as Portland cement, coal fly ash and ground ...

EC Cement Plant

Egyptian Cement greenfield plant is loed at Suhag Governorate, about 400 KM south Cairo. It is the newest Cement Plant in Egypt and the region established on area around one million m2 and equipped with the latest technology. the production line using the dry process method with capacity 6000 TPD clinker, however the plant designed to reach a maximum capacity of 6500 TPD clinker.

Latest Posts

- بيع كسارات محجر الحجر

- allis chalmer مخروط محطم المواصفات

- عملية الطحن الخشنة

- كسارات خرسانية مدمجة من جورجيا

- مشروع محطة تكسير الحجر الآلي

- وتعدين كسارة للبيع السعودية

- كسارة الحجر متوسطة الحجم المصنوعة في الصين

- سعر معدات البناء

- دروس كسارة الحجر

- محول مطحنة نهاية

- حجر الكامل سحق تركيب محطة

- الآلي آلة طحن لخامات الحديد

- كسارات استبدال الفك لكسارة الصخور كسارة الصخور الصغيرة

- مشاريع للاستفادة من مسحوق الرخام

- تستخدم كسارة الفك المحجر

- Spesifikasi Mesin Giling Grinder R

- Quarries Machines Fit For Lizenithne Sandstone

- Basic Operation Of A Milling Machine

- Homemade Sand Washing Machine

- Celite Crusher Machine Manufacturer

- Disadvantages Of John Mills Theory

- Marble Manufacturing Flow Cahrt

- Line Cost Price Mobile Crusher

- Tile Production Equipment

- Grinding Aid For Limestone Powder Production

- Stone Crusher Albania 36 8

- Mobile Li Ne Crusher Typemobile Li Ne Crushing Plant

- Crushing And Grinding Copper

- Pengumuman Ajendam Siliwangi

- Crusher For Sale Is The