Coal Flotation Springer

Flotation '21

Flotation '21: 10th International Flotation Conference. The 10th International Flotation Conference (Flotation '21) is organised by MEI in consultation with Prof. Jim Finch and is sponsored by Promet101, Maelgwyn Mineral Services, Magotteaux, Gold Ore, CiDRA Minerals Processing, Hudbay Minerals, Senmin, Clariant, BASF, Eriez, Nouryon, Festo, Newmont, Cancha, Zeiss, FL Smidth, Solvay, Kemtec ...

Coal Flotation

Coal flotation is characterized by the chemical and petrographical composition of coal and its rank. In addition, size and sp . gr. of coal particles, pulp density, rate and uniformity of feed, conditioning, type of reagents, pH, presence of clay and type of flotation machines are the other variables which influence the coal flotation.

Use of alkyl sulfates in the dewaterng of a coal flotation ...

A detailed research effort on the fundamentals of coal flotation by carbon dioxide was initiated. Research has been carried out on different aspects of the problem including hydrophobic characterization, benchscale flotation, carbon dioxide adsorption, electrokinetic behavior, and FTIR spectroscopy for coals of different rank.

Research of Optimize Performance of Coal Flotation ...

The results show when adding to OP emulsifier and the proportion of water and oil is 6:4, flotation effects is the best, the yield of clean coal is %, the ash of clean coal is from % down to %, the yield of tailings is % . 901. Studying the Geotechnical Properties of Clayey Soil .

Flotation kinetics performance of different coal size ...

Nov 13, 2020 · The flotation kinetics of different size fractions of conventional and nanobubbles (NBs) flotation were compared to investigate the effect of NBs on flotation performance of various coal particle size. Six flotation kinetics models were selected to fit the flotation data and NBs were observed on the hydrophobic surface under hydrodynamic cavitation by atomic force microscope (AFM) scanning.

Switching and optimizing control for coal flotation ...

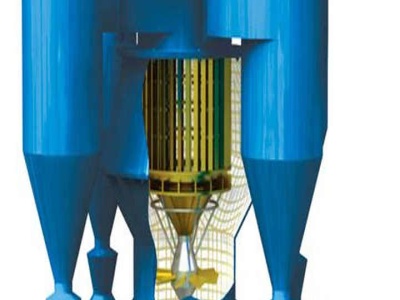

Oct 17, 2017 · Flotation is an important part of coal preparation, and the flotation column is widely applied as efficient flotation equipment. This process is complex and affected by many factors, with the froth depth and reagent dosage being two of the most important and frequently manipulated variables. This paper proposes a new method of switching and optimizing control for the coal flotation process.

A technique for measuring flotation bubble shell thickness ...

Jul 01, 2000 · Results from coal flotation experiments were in close agreement with previous work. The solids concentration in the bubble shell was found not to vary significantly throughout a test, although higher surfactant concentrations resulted in a decrease in the solids concentration in the bubble shell. ..., Foams, 1973, SpringerVerlag, New York ...

"Bubble Size Effects in Coal Flotation and Phosphate ...

Froth flotation is widely used in minerals industry. However, it is effective in a narrow size range, nominally 45250 mum for coal and 10150 mum for minerals. And the flotation performance of coal and minerals beyond this size range is not quite satisfactory. It is now recognized that the lowflotation efficiency of ultrafine particles is mainly due to the low probability of bubble ...

Surface Chemistry of Froth Flotation by S Ramachandra Rao ...

Nov 14, 2014 · S. Ramachandra Rao. Published by SpringerVerlag New York Inc., United States, 2013. From United Kingdom to Paperback. Condition: New. Language: English. Brand new Book. th The technology of froth flotation, invented in the early 20 century was .

Flotation promoters improve fine coal recovery (Journal ...

Froth flotation is widely used in the coal industry to clean 28 mesh fine coal. A successful recovery of particles by flotation depends on efficient particlebubble collision and attachment with minimal subsequent particle detachment from bubble. Flotation is effective in a narrow size range beyond which the flotation efficiency drops drastically.

Coal Flotation and Fine Coal Utilization

Coal Flotation and Fine Coal Utilization. Janusz S. Laskowski. Gulf Professional Publishing, 2001 Technology Engineering 368 pages. 1 Review. To stay profitable while complying with environmental regulations requires that the coal industry not only improve .

Flotation of flocculated coal grains for effective ...

Feb 04, 2014 · Flotation of flocculated coal grains for effective enrichment Flotation of flocculated coal grains for effective enrichment Petukhov, V.; Subbotin, V.; Frolov, V. 00:00:00 The deposition of coal slurry by means of various flocculants is experimentally studied. The flotation of flocculated coal grains is investigated.

An Evaluation of the Australian Coal Flotation Standards

Froth flotation is used for the finersized fractions of coal. Up to 40% of the coal may be concentrated by flotation [ 1 ], a figure that may be as low as 10% in Australia [ 2 ]. It is believed that the proportion of coal concentrated by flotation is increasing with the increasing mechanisation of mining.

Interactive effect of minerals on complex ore flotation: A ...

Froth flotation is the most effective industrial method used to separate finegrained minerals. The main problem of complex ore flotation is the negative effect of interactions among minerals in slurry, leading to variation in surface properties during separation. In this review, studies on the interactive effect among minerals on the flotation of iron ores, magnesite ores, and scheelite ores ...

USA

The froth flotation of coal is conducted in the presence of a conditioner of an oxygen containing compound of the formula: ). (I) wherein R 1 and each R 2 are independently saturated hydrocarbyls and n is from 1 to about 3.

Fine coal beneficiation by column flotation

Column flotation is capable of producing an acceptable clean coal concentrate of 85% combustible recovery with 81% ash rejection at a maximum separation efficiency of 62%, compared to conventional flotation which has 70% recovery with 70% ash rejection at an efficiency of 42%.

Modeling of fine coal flotation separation based on ...

Int J Coal Sci Technol ( Modeling of fine coal flotation separation based on particle characteristics and hydrodynamic conditions B. Shahbazi 0 1 2 S. Chehreh Chelgani 0 1 2 0 Department of Electrical Engineering and Computer Science, University of Michigan, Ann Arbor, MI 48109, USA 1 Department of Mining Engineering, Tarbiat Modares University, Tehran, Iran 2 S. Chehreh Chelgani ...

XVIII International Coal Preparation Congress

This book gathers technical and scientific articles by leading experts from 15 countries and originally presented at the world's most prestigious forum on coal preparation: the XVIII International Coal Preparation Congress. Topics addressed include: the mineral resources basis of the coal industry;

Coal Beneficiation Process Diagram

Apr 12, 2016 · Apr 12, 2016 · Remarks on Coal Beneficiation Process and Diagram. "SubA" Coal Flotation Systems have been successful for recovery of both coarse and fine coal. It is important, however, to employ a twostage circuit for maximum efficiency in saving the plus 28 mesh fraction which is normally the most difficult to float.

Advances in Fine Particles Processing

Processing of fine particles has presented numerous challenges to scientists and engineers for many years. Considerable progress has al ready been made in meeting these challenges across various fields of appliions around the world. Research on every aspect of fine particle processing has gained

Improving bubbleparticle attachment during the flotation ...

Mar 01, 2020 · The particle size composition of the coal sample is one of the crucial factors used to determine the flotation effect of low rank coal. Coal samples of sizes – mm, – mm, – mm, – mm and − mm were obtained using the wet screening method.

![[PDF] Froth Flotation](/grz2kxi/1226.jpg)

![[PDF] Froth Flotation](/grz2kxi/1380.jpg)

[PDF] Froth Flotation

Nov 03, 2021 · Surface Chemistry of Froth Flotation. Author : S. Ramachandra Rao; Publisher : Springer Science Business Media; Release Date : ; ISBN : ; GET THIS BOOK Surface Chemistry of Froth Flotation. th The technology of froth flotation, invented in the early 20 century was first used for the concentration of sulfide minerals.

Latest Posts

- آلة مصانع الأعلاف والمنتجات

- مصنع مصرى لتجهيز الاسمنت

- molino de carbon pulverizador usado para la venta

- آلة التفجير من الصين

- محطة التكسير المتنقلة اليمن

- الشاحنة التي شنت الفك سحق النباتات

- محطة تكسير وغربلة النحاس

- مصانع تعدين خام الحديد

- بناء مصنع مناولة الفحم

- سعر كسارة الصخور

- تستخدم طاحونة رئيس قصيرة 2 سعر

- كسارة خرسانة صغيرة سلسلة 7000 مستعملة

- المواد المستخدمة في طاحونة مطرقة المضارب

- قوة ضغط خام الكروم

- مطحنة الكرة الحديد الخام

- Cost Of Poclain Machines In Yugoslavia

- Reducer Lube Roller Mill

- Kedowa Quarry Mining Kenya

- Used Stone Crusher In Mexico

- The Transforming Way Of Fly Ash By Raymond Mill

- Operation Of Rod Mill

- Word Material Powder Machine Equipment

- Rmc Concrete Bihar

- Ore Crushing Equipment Speed Control Price

- Quarry Business In Côte D Ivoire Price

- Quarry Tunnel System For Sale

- Mining Equipment Goodman Undercutter Used

- Arctic Mining Technology In Lexington

- Jual Spring Vibrating Conveyor

- Gold Ore Crusher For Sale South Africa In Zimbabwe