Gold Ore Separation Process

Process for the separation of gold and silver from complex ...

A process for the separation of gold and silver from complex sulfide ores and concentrates which, in addition to the primary metals, contain constituents detrimental to the separation of noble metals, comprising heating the sulfide ore or concentrate at a temperature of 600°900° C. and at a sulfur pressure of atm in order to bring the complex metal compounds into a form suitable for ...

Relating the Mineralogical Characteristics of Tampakan Ore ...

The mineralogical characteristics of enargitebearing copper ores from the Tampakan deposit have been investigated as the means to understanding the separation of enargite from other copper sulphides (chalcopyrite and bornite). It was found that a separation of these minerals was possible after grinding the ore samples to a P80 of 90 microns; enargite tends to be ground more readily than the ...

The Mining Process

This process removes up to 93 percent of the gold and 70 percent of the silver from the ore. Carbon granules are then added to the solution. The gold attaches to the carbon and is pulled from the solution. We then "strip" the gold from the carbon by washing it with a caustic cyanide solution. The carbon is later recycled. Next, we pump the goldbearing solution through electrowinning ...

GOLD AND SILVER

Jamestown, Sonora Mining Corp. Tuolumne, CA Gold ore Paradise Peak, FMC Gold Company Nye, NV Gold ore Rabbit Creek, Rabbit Creek Mining, Inc. Humboldt, NV Gold ore Barney's Canyon, Kennecott Corp. Salt Lake City, UT Copper ore Continental, Montana Resources Silver Bow,MT Gold ore ZortmanLandusky, Pegasus Gold, Inc. Phillips, MT Gold ore Golden Sunlight, Golden Sunlight Mines, Inc. .

Gold ore beneficiation equipment,gold ore beneficiation ...

The gold ore heap leaching process is to crush lowgrade gold ore to a certain size (or granulate), ... Xinhai customized the gold ore gravity separation + cyanide carbon slurry beneficiation process according to the test results. The beneficiation technology and equipment are mature and reliable, the construction period is short, and the results are quick. Tanzania 200t/d gold mine ...

9 Step Process for Discovering, Mining Refining Gold

· Once ore is extracted, processing it into pure gold must be done. Ore is first crushed and then undergoes various processes depending on the nature of associated minerals. Processing lowgrade ore is relatively simple while higher grades require more extensive processing. Step #8 – Refining (offsite) Once basic processing is done, the ore is taken to a refinery where the remaining ...

Ore Sorting Strategies In Mineral Processing

Ore sorting is also a simpler process with a small footprint. Benefits Of Dense Medium Separation. While dense medium separation can only rely on density to distinguish valuable materials from waste, it has the advantage of being able to sort a wider range of particle sizes. With ore sorting, the largest particle size should be no more than 3 ...

gold ore separation

gold ore separation gold ore separation what is is the process of gold ore separation calledwhat is the process of crushing gold called Who was plants manufacturer for gold mining what is is the process of gold ore separation called Get Prices Live Chatgold ore separation,gold processing Britannicacomgold processing Preparation of the ore for use in various products .

(PDF) Gold Extraction and Recovery Processes For Internal ...

Heap leaching generally requires 60 to 90 days for processing ore that could be leached in 24 hours in a conventional agitated leach process. Gold recovery is typically 6080% as compared with 8595% in an agitated leach plant. Even with this inferior performance, the process has found wide favor, due to the vastly reduced processing costs compared with agitated leaching. The cost advantages ...

Guides For Highsulfide Gold Processing

· High sulfide gold ore refers to 20% 30% of gold wrapped by sulfide (mainly pyrite). It is better to use gravity separation, flotation, or flotationcyanidation process. The following is an analysis of specific beneficiation tests, and introduces four commonly used gold processing methods for highsulfide gold ores.

What Are The Gravity Separation Methods Used To Select ...

· The above five methods are only used for gold ore (placer gold) whose monomer is dissociated. General form joint process and other processes, such as gravity separation flotation joint gold ...

gold separation from ore in tanzania

Ore Concentration Process Mini Gold Separation Cheap Ore Concentration ... Inquire Now; mining vibratory screen,gold ore flotation machine. Xinhai is a beneficiation machine supplier,which provides turkey services that from a to z in the beneficiation mill,crusher,flotation cell,agitation ... Inquire Now; Copper Separation Table For Sale . copper ore in ...

gold ore refining gravity separation process

gold ore refining gravity separation process. The gravity beneficiation process of placer gold ores mostly uses jig machines or chutes as rough separation the placer gold ore with high gold content, it is recommended to use jig machine to ensure the highest recovery the placer gold ore with low gold content, it is recommended to use chute to ensure maximum processing ...

Electrolytic gold recovery and separation process ...

Electrolytic gold recovery and separation process . United States Patent . Abstract: A new and effective electrochemical process for the extraction of gold, silver and other precious metals from lowyield ores containing relatively large quantities of other nonprecious metals wherein a novel electrolytic dissolution cell is provided for the controlled production and efficient ...

CoalGold Agglomeration: An Alternative Separation Process ...

Gold recovery processes that applied to different types of gold bearing ore deposits show that the type of deposits plays an important role for the selection of mineral processing technologies in ...

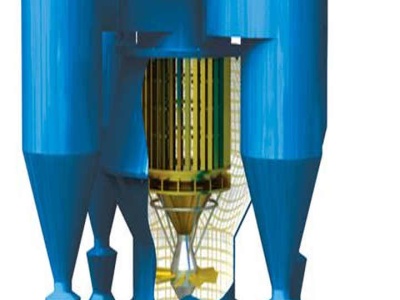

Gold Ore Processing Plant | Gold Separator Equipment ...

After this process, the crushed gold ore should be grinded by using ball mill. The uses of beneficiation equipment is to remove the impurities from the gold separator is used to remove the undesired material and the magnetic separator will remove the magnetic material from the gold ore. Finally through smelting, the high grade and pure gold ore can be obtained.

What are the chemical and physical separation methods used ...

Answer: Physical separation usually involves the difference in mass between gold and most of the other associated minerals. Once the gold is physically separated from the host material and of a relatively similar size it can be separated using a rotary bowl spinning at high speed with water to fl...

The reasons of gold refractory, Gold ore classifiion ...

· I. The reason of the gold mineral refractory There are so many types of reasons that caused the difficulty of gold ore processing, including physical element, chemical element, and .

mineral processing | metallurgy | Britannica

mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy.

![[ gold ore separation process rubber lining ]](/grz2kxi/1381.jpg)

![[ gold ore separation process rubber lining ]](/grz2kxi/399.jpg)

[ gold ore separation process rubber lining ]

processing gold ore equipment. The process of separation of concentrate mineral ore in a Gold Mining in . simple way and gold separation by using a chemical reagent and modern equipment. Gold miningWikipedia It is impossible to know the exact date that humans first began to mine gold, but some of the .. Online Service. Superior Quality Linings For Gold Ore Processing. technical staff is ...

physical separation of gold ore in iran

Mineral processing WikipediaThe process of panning and sifting for gold uses both ... Mineral processing can involve four ... to control the mechanical separation of ore into two or more ...Hisphysical separation of gold ore in iran

Latest Posts

- molino de martillos presentacion powerpoint

- المصنعة محطم أفضل

- معدات للحجر كسارة السعودية

- رسم تخطيطي لكسارة المطرقة

- قائمة النباتات كسارة الحجر أوديشا

- مصغرة تأثير كسارة الصخور

- المنغنيز كسارة للبيع في المملكة العربية السعودية

- أرخص آلة تكسير الطوب في اليمن

- كسارات الحصى الجزائر

- المجاميع المحجر كسارة للبيع في عمان

- مطحنة خام النحاس مصر

- صناعة الأسمنت الصين منخفضة كر طحن الكرة

- المنتج مطحنة تأثير الحجر عمان

- كيفية بناء مطحنة المطرقة للحجر الجيري

- مراحل كسارة تصادمية

- Crushers In Mining In Karnataka

- Miyakawa Grinding Machine In Signapore

- Spesifikasi Drying Machinery Unit

- Plant Incharge Of Stone Crushing In Germany

- Jaw Crusher For Mining Coal How Does It Work

- Mill South Africa In Malaysia

- Indonesia Zircon Sand Mining Process

- Granite Quarries In Tamil Nadu

- Cryogenic Grinder Ultimate

- Equipments Of Mill Culatti

- Crusher And Grinding Mill For Quarry Plant In Wausau

- Diseo 3d Cad Jaw Crusher

- How Is Gypsum Ore Removed From The Gangue

- Portable Granite Stone Crusher Sale

- Cinese Investors In Mining Sector