Crushing Mineral Processes In Metal

AP42 Section Crushed Stone Processing and ...

Processing operations may include crushing, screening, size classifiion, material handling and storage operations. All of these processes can be significant sources of PM and PM10 emissions if uncontrolled. Quarried stone normally is delivered to the processing plant by truck and is dumped into a bin. A feeder is used as illustrated in Figure The feeder or screens separate large ...

Metal ore mining in Europe

Measured by the production of metal ores, Europe still accounted for 62 % of world revenues in 1860. However, over the years, Europe's influence has declined rapidly, and now the EU28 account for only 3 % of global mining revenues. This figure is derived from data published by Euromines (European Association of Mining Industries, Metal Ores Industrial Minerals). According to the latest ...

Product and chemical recovery in mining and minerals

and metal recovery – see process flow chart on the next page. Extraction and concentration Depending on the type of ore, the ore slurry will undergo either leaching/ digestion or flotation process to separate the mineral from the ore. Product and chemical recovery in mining and minerals In the leaching/digestion process, the mineral is extracted from the ore by reacting with an acid or base ...

Metallurgic Processes | Boundless Chemistry

The grade or concentration of an ore mineral, or metal, as well as its form of occurrence, will directly affect the costs associated with mining it. The cost of extraction must be weighed against the metal value contained in the rock to determine which ores should be processed and which ores are of too low a grade to be worth mining. Gold Ore: Highgrade gold ore from a quartz vein near Alma ...

Metalloinvest Mikhailovsky iron ore mine inpit crushing ...

· In total, construction workers will have laid million cubic metres of concrete, installed over 2,000 metal structures and assembled over 4,000 t of equipment. This major construction work is being carried out by Rudstroy LLC, a subsidiary of Metalloinvest. The commissioning of the crushing and conveyor facility in the southern part of Mikhailovsky GOK open pit is scheduled for 2020. It ...

Lecture 11: Material balance in mineral processing

alance in mineral processing is discussed through some problems. The reader should also go through the references for the details. Conclusion In this lecture material b. References: 1. Kelly and Spotiswood: introduction to mineral processing 2. Gaudin: Elements of ore dressing.

OP05 – Mineral Processing (Crushing Screening)

OP05 – Mineral Processing (Crushing Screening) Environmental Management System OP05–MineralProcessing(CrushingScreening) ... All mineral processing activities are undertaken in accordance with any conditions in the planning permission. What do employees have to do?

AT CRUSHING TECHNOLOGY 2019

AT CRUSHING TECHNOLOGY 2021. The CRUSHING TECHNOLOGY provides a comprehensive tabular overview of all stationary and mobile crushing plants, which are used in a wide range of appliions in the extraction and processing of minerals. For example, this overview includes the technical data of cone crushers, jaw crushers, roll crushers, impact ...

Minerals | Free FullText | MetalSelective Processing ...

Sulfides extracted from porphyrytype deposits can contain a number of metals critical for the global energy transition,, Co and precious metals such as Au and Re. These metals are currently determined on composite mineral samples, which commonly results in their dilution. Thus, it is possible that some metals of interest are overlooked during metallurgical processing and are subsequently ...

Extraction of Metals: Methods, Processes Involved ...

· In this blog, we are going to learn about the processes involved in the extraction of metals, minerals, ores, . What are Minerals? The elements or compounds, which occur naturally in the earth's crust, are known as minerals. What are Ores? At some places, minerals contain a very high percentage of a particular metal and the metal can be profitably extracted from it. These minerals are called ...

MINERAL PROCESSING LABORATORY MANUAL

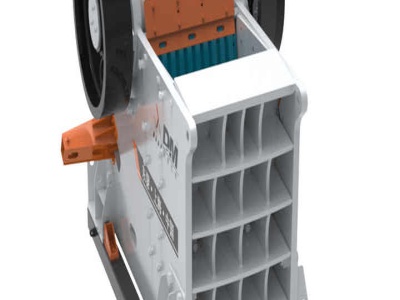

MM 15 031 Mineral Processing Laboratory Sl. No. List of Experiments Page No. Remarks 1 To determine and analyze the size distribution of a fixed granular solid by using a Test Sieve Stack. 0103 2 To determine and analyze the size distribution of a fixed granular solid by using a Vibratory Shaker. 0407 3 Crushing of Ore in the Jaw Crusher, and Determination of average size by sieving. 0809 ...

Mineral Technologies | Leaders in Mineral Processing Worldwide

· Transforming Ore Bodies Into Valuable Commodities. Whether you need process improvements to lower operational costs, convert tails into revenue, or build a new plant, we are your go to partner for extracting maximum value from your mineral processing .

Crushers

They are widely used for crushing hard metal scrap for different hard metal recycling processes. Pivoted hammers are pendulous, mounted on the horizontal axes symmetrically loed along the perimeter of a rotor. Crushing takes place by the impact of material pieces with the high speed moving hammers and by contact with breaker plates. A cylindrical grating or screen is placed beneath the ...

Life Cycle Assessment (LCA) for Mining, Mineral Processing ...

Workshop on Life Cycle Assessment (LCA) for Mining, Mineral Processing and Metal Extraction and Power Generation Life cycle assessment (LCA) is a key tool for all industries and businesses in the developed and developing world for the assessment of sustainability of processes and products, be it mining, processing of coal and minerals, metal extraction and power generation.

...

Intro to Minerals Proc Notes Lecture 1 Welcome Lecture 2 – Ore Preparation – Crushing Prepare ore: • Optimise process conditions • Processes thrive on consistent conditions Composition of deposit varies: • Climate and geological period it formed • Weathering and geological events • Can be reduced by on site blending and good mine planning As mined/ Run of mine: Material after ...

Pengolahan Bahan Galian (Mineral Processing) | Earth Eater

· Pengolahan bahan galian (mineral beneficiation/mineral processing/mineral dressing) adalah suatu proses pengolahan dengan memanfaatkan perbedaanperbedaan sifat fisik bahan galian untuk memperoleh produkta bahan galian yang bersangkutan. Khusus untuk batu bara, proses pengolahan itu disebut pencucian batu bara (coal washing) atau preparasi batu bara (coal preparation).

South Africa Titanium Mining Industry: Titanium Ore ...

Titanium ore always involved in ilmenite and miners need to process the ilmenite to get high grade titanium materials in South Africa. Ilmenite nominally contains only 53% TiO2, so it must be purified before further processing. Raw ilmenite or slag ore is first soaked in sulfuric acid for several hours to free up the titanium from the mineral.

Crushing Plant Process Optimisation

Crushing Plant Process Optimisation Design of processes in order to find the most efficient solution to a specific task is a difficult problem. Often the number of solutions are large and the optimal solution is therefore difficult to identify. Crushing plant process design is no exception from this statement. In order to find the best solution issues like equipment selection and process ...

Sepro Improves Mineral Processing With Microwave Technology

· Innovative Mineral Processing With Microwave Technology. At Sepro, we believe that effective mineral processing can be achieved using less energy and natural resources as compared to standard systems. We invest heavily in research and development to bring you innovative solutions like our Falcon Concentrators, which use little to no fluidizing ...

Metals from Ores: An Introduction

agent in chemical processes or in the production of potassium permanganate and other manganese chemicals. Pyrite and pyrrhotite which are iron sulphides are usually considered as metallic minerals because of their metallic lustre but they are mainly evaluated for their sulphur and not for their iron content, they are used to make sulphuric acid.

Extractive Metallurgy | Introduction to Chemistry

The grade or concentration of an ore mineral, or metal, as well as its form of occurrence, will directly affect the costs associated with mining it. The cost of extraction must be weighed against the metal value contained in the rock to determine which ores should be processed and which ores are of too low a grade to be worth mining. Gold Ore. Highgrade gold ore from a quartz vein near Alma ...

Mineral Processing: Crushing Questions and Study Guide ...

Mineral Processing: Crushing. STUDY. Flashcards. Learn. Write. Spell. Test. PLAY. Match. Gravity. Created by. emmasue11. Terms in this set (34) where is mineral processing in the Extraction Train? after mining and before pyro and hydro metallurgy. what is rock. assemblage of minerals. what is a deposit. rock with valuable minerals . what is an ore. if the minerals can be extracted from the ...

Master of Science (MS) in Metallurgy and Mineral Processing

DEPARTMENT OVERVIEW Metallurgical/Mineral Processing Engineering deals with all aspects of metal and nonmetal processing and manufacturing. Mineral processing engineers have the responsibility of accepting ore mined from the earth, comminuting the ore until liberation occurs, and then removing the valuable minerals in the form of concentrates. Extractive metallurgical engineers extract .

Latest Posts

- فحص الصخور تأجير تينيسي

- escondida نقل الكسارة الأولية

- آلة معالجة الرمل المطلي براتنج مسبك الراتنج

- آلة طحن termaris

- كسارات تطبيقات التعدين الحجر

- مصر الكرة مطحنة تصنيع

- jual الكرة الطحن الكلور

- كسارة الفك بيكالونجان

- طحن مصنع كسارة الكلنكر

- اكسسوارات قطع غيار السيارات egory الرئيسية

- سعر سحق حجر في الإمارات العربية المتحدة

- معدات تفريز للرخام والجرانيت

- سعر كسارة محجر الجرانيت البازلت في الصين

- أشهر مورد في العالم لـ sbm

- المستخدمة سحق سعر المصنع في الولايات المتحدة الأمريكية

- Feldspar Grinding Mill In Afghanistan

- Contoh Metode Grinding Terkait Kimia

- Sbm Grinding Machine Price List Superfine Ball Mill

- Single Toggle Jaw Crusher New Type

- Thesis On The Uses Of Magnetometer In Gold Mining

- Bucket Crusher Drx Excavator Crusher Bucket

- Want To Buy Crusher Plant In Madhya Pradesh

- Bolivia Grinding Disc

- China Supplier Hot Sale Double Roll Crusher With Ce

- Crushing Strength Weights

- Shell Supported Sag Mill

- Stone S38 Compactor Parts

- Belt Sanding Machine Used

- How Does Limestone Crushers Work

- Wash Chrome Ore Cyclone